Frozen processing method for pignolia

A processing method, matsutake technology, applied in the direction of freezing/refrigerating fruits/vegetables, etc., can solve the problems of nutrient loss and short storage period, and achieve the effect of long storage time and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A freezing processing method of matsutake, comprising the following steps:

[0020] Select fresh matsutake, wash and dry, cut into 1-3cm thick slices;

[0021] Quick-freeze the matsutake and stop when the central temperature of the matsutake reaches -18°C;

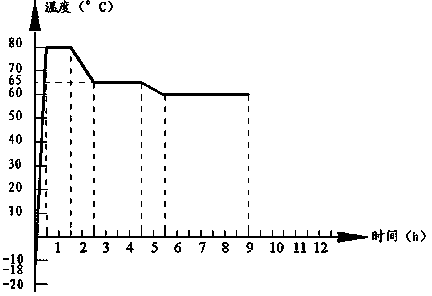

[0022] Quick-freezing stops when the central temperature reaches -18°C; the drying process is to raise the temperature to 80°C at a uniform speed within 0.5h and keep it for 1.0h; drop the temperature to 65°C at a uniform speed within 1h and keep it for 2.0h; let the temperature drop at a uniform speed within 1.0h To 60 ℃, keep 3.5h.

[0023] Optionally, vacuum or nitrogen-filled packaging of the dried matsutake is also included.

Embodiment 2

[0025] A freezing processing method of matsutake, comprising the following steps:

[0026] Select fresh matsutake, wash and dry, cut into 1-3cm thick slices;

[0027] Quick-freeze the matsutake, and stop when the central temperature of the matsutake reaches -20°C;

[0028] The drying process was as follows: within 0.4h, the temperature was raised to 78°C at a constant speed and kept for 1.3h; for 0.8h, the temperature was dropped to 68°C at a constant speed, and kept for 1.5h; for 0.8h, the temperature was dropped to 62°C at a constant speed, and kept for 4.0h.

[0029] Optionally, vacuum or nitrogen-filled packaging of the dried matsutake is also included.

Embodiment 3

[0031] A freezing processing method of matsutake, comprising the following steps:

[0032] Select fresh matsutake, wash and dry, cut into 1-3cm thick slices;

[0033] Quick-freeze the matsutake, and stop when the central temperature of the matsutake reaches -16°C;

[0034] The drying process was as follows: within 0.6 hours, the temperature was raised to 82°C at a uniform rate and kept for 0.8 hours; for 1.2 hours, the temperature was dropped to 62°C at a constant rate, and kept for 2.5 hours; for 1.2 hours, the temperature was dropped to 57°C at a constant rate, and kept for 3.0 hours.

[0035] Optionally, vacuum or nitrogen-filled packaging of the dried matsutake is also included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com