A comprehensive processing method of bagged Pu'er tea snus

A comprehensive processing and snus technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve the problems of snus product taste comfort, poor sense of satisfaction and excitement, difficult dissolution and transformation of contained ingredients, and limitation of oral tobacco products. To solve problems such as the development of tobacco-containing products, to achieve the effect of improving excitement, flavor quality and health care efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

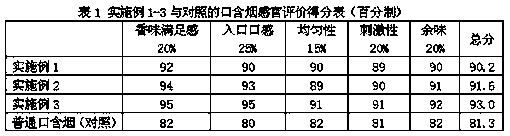

Examples

Embodiment 1

[0024] 1) Collect fresh tea tree leaves according to the standards of three or four leaves per bud and the same tenderness for clipping leaves, add the tobacco leaves that are ground to a particle size of 22 mesh into the fresh tea leaves, stir evenly, and then sprinkle water with the amount of fresh tea leaves and 9% of the weight of tobacco powder, and then it is fixed, the temperature of the fixing pot is 285 ° C, and the amount of leaves per pot is 8 kg;

[0025] 2) The mixture of tea leaves and tobacco powder after greening is first kneaded with a tea kneading machine. The initial kneading time is 14 minutes, the amount of leaves is 21 kg, and the pressurization adopts the method of "light pressure → heavy pressure → light pressure";

[0026] 3) After the initial kneading, the mixture of tea leaves and tobacco powder is taken out from the kneading machine, and then processed into piles. The ambient temperature of the piles is 26°C, the relative humidity of the environment ...

Embodiment 2

[0032] 1) Collect fresh tea tree leaves according to the standards of three or four leaves per bud and the same tenderness for clipping leaves, add the tobacco leaves that are ground to a particle size of 25 mesh into the fresh tea leaves, stir evenly, and then sprinkle water with the amount of fresh tea leaves and 9% of the weight of tobacco powder, and then it is fixed, the temperature of the fixing pot is 295 ° C, and the amount of leaves per pot is 10 kg;

[0033] 2) The mixture of tea leaves and tobacco powder after greening is first kneaded with a tea kneading machine, the initial kneading time is 16 minutes, the amount of leaves is 20 kg, and the pressurization adopts the method of "light pressure → heavy pressure → light pressure";

[0034] 3) After the initial kneading, the mixture of tea leaves and tobacco powder is taken out from the kneading machine, and then processed into piles. The ambient temperature of the piles is 28°C, the relative humidity of the environment...

Embodiment 3

[0040] 1) Collect fresh tea tree leaves according to the standard of three or four leaves per bud and the same tenderness for clipping leaves, add the tobacco leaves that are ground to a particle size of 30 mesh into the fresh tea leaves, stir evenly, and then sprinkle water with the amount of fresh tea leaves and 10% of the weight of tobacco powder, and then it is fixed, the temperature of the fixing pot is 305 ° C, and the amount of leaves per pot is 12 kg;

[0041] 2) The mixture of tea leaves and tobacco powder after greening is first kneaded with a tea kneading machine, the initial kneading time is 15 minutes, the amount of leaves is 23 kg, and the pressurization adopts the method of "light pressure → heavy pressure → light pressure";

[0042] 3) After the initial kneading, the mixture of tea leaves and tobacco powder is taken out from the kneading machine, and then processed into piles. The ambient temperature of the piles is 29°C, the relative humidity of the environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com