Snus barrel packaging device

A technology for snus and box sealing, which is used in packaging, wrapping paper, packaging protection, etc., can solve the problems of good sealing quality, difficult laminated sleeve labeling, poor appearance and sensory quality, etc., to improve the neatness and high market. The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

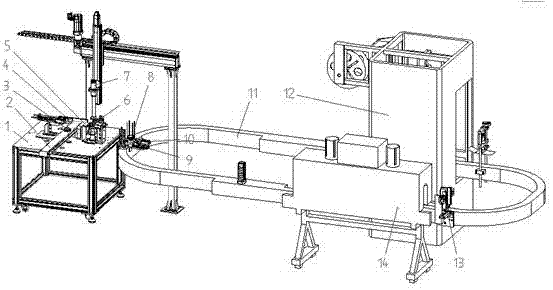

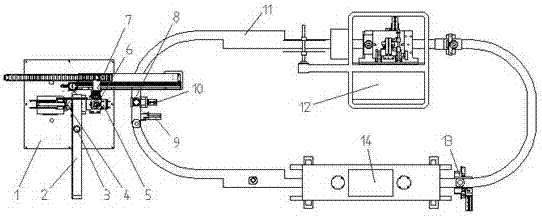

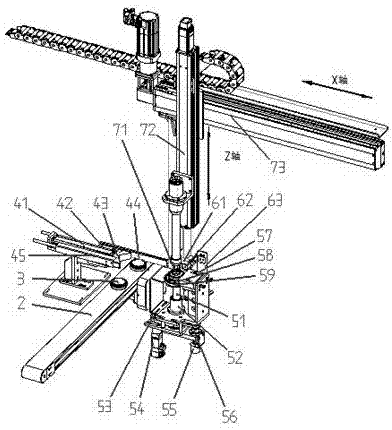

[0034] Such as Figure 1-7 Shown: a packaging device for cigarette packs, including a visual inspection platform and a sleeve label packaging line, on which a visual inspection turntable 5, a visual inspection device 6, a material pushing cylinder assembly 4, and a small box are arranged on the visual inspection platform 1 Conveyor 2 and Cartesian coordinate manipulator 7. The sleeve label packaging line includes a sleeve label machine 12, a heat shrink furnace 14 and a circulation conveying line 11. Several carton transfer molds 8 and positioning components 10 are also placed on the circulation conveying line. Installed on the end of the circulating conveying line close to the detection platform, above it is the stacking station of the Cartesian coordinate manipulator 7, and the distribution component 9 is installed next to the positioning component, which is used to make the transfer mold 8 enter the stacking station orderly one by one;

[0035] The pusher cylinder assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com