Method for adsorbing tobacco-specific nitrosamines in tobacco power of snus

A nitrosamine and snus technology, applied in the directions of tobacco, tobacco treatment, application, etc., can solve the problems of long time, difficulty, and difficult control of the distribution of adsorbent materials, so as to improve the utilization rate, promote uniform adhesion, and improve the The effect of adsorption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The water content of the used tobacco powder is generally about 10% (weight ratio, the same below) after determination. In view of this, 2 g of distilled water was added to 4 g of Burley tobacco powder and mixed thoroughly to obtain tobacco powder with a water content of about 40%, which was sealed and left to stand for more than 24 hours for later use.

[0025] At room temperature, weigh 300mg of tobacco powder A with a water content of 40% and 8mg of UK-made coconut shell activated carbon, and the prepared fine powder is 400 mesh adsorption material, fully mix in a closed container for 2min and let stand for 6h. Then, 20ml of distilled water was added to seal it, and it was shaken on a shaker-absorbed for 20min. Decant the upper layer solution into two 10mL syringes, and filter each 10mL syringe with three 0.45μm water filter membranes until the liquid can no longer be decanted, and the solution to be tested is sent to the LC-MS / MS instrument to detect its TSNA conten...

Embodiment 2

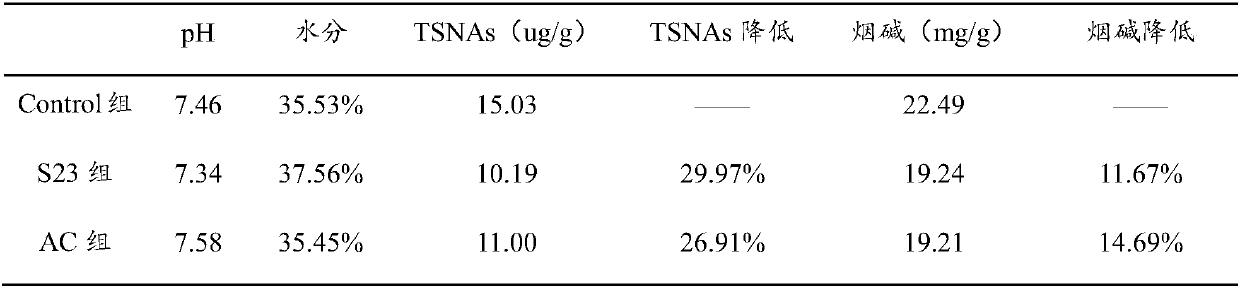

[0031] At room temperature, weigh 300 mg of tobacco powder C with a water content of 40% and 8 mg of French Picca activated carbon S23-NaOH fine powder (400 mesh) as adsorption materials, mix them in a closed container at room temperature for 1.5 min and let stand for 6 h. Then, 20 mL of distilled water was added to seal it, and it was shaken on a shaker-absorbed for 20 min. Decant the upper layer solution into two 10mL syringes, and filter each 10mL syringe with three 0.45μ. .

[0032]The original TSNA content of tobacco dust C was about 50.97 μg / g. After "in-situ adsorption" of 400 mesh fine powder of French Picca activated carbon S23-NaOH with 4% added amount, the TSNA content of the tobacco powder was reduced to 29.74μ9.7, and about 42% were removed by adsorption.

[0033] The 400-mesh fine powder of French Picca activated carbon S23-NaOH with 4% addition was still used to carry out "in-situ adsorption" on the tobacco dust C, but after the addition of activated carbon, t...

Embodiment 3

[0040] At room temperature, weigh 300 mg of smoke dust C with a water content of 40% and 8 mg of British coconut shell activated carbon fine powder (400 mesh) adsorption material, mix in a closed container at room temperature for 1.5 min and let stand for 6 h. Then, 20 mL of distilled water was added to seal it, and it was shaken on a shaker-absorbed for 20 min. Decant the upper layer solution into two 10mL syringes, and filter each 10mL syringe with three 0.45μm water filter membranes until the liquid can no longer be decanted, and the solution to be tested is sent to the LC-MS / MS instrument to detect its TSNA content.

[0041] The original TSNA content of tobacco dust C was about 50.97 μg / g. After the 400-mesh fine powder of British coconut shell activated carbon with 4% added amount was left to stand for "in-situ adsorption", the TSNA content of the tobacco powder was reduced to 35.54μ5.5, and about 30% was removed by adsorption.

[0042] After "in situ adsorption" treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com