Method for applying tobacco flavor extracted from tobacco branches to snus

A flavoring and snus technology for tobacco, applied in the field of snus, can solve problems such as environmental pollution and waste of resources, and achieve the effects of reducing pollution, avoiding waste, and avoiding organic solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for extracting tobacco spices from tobacco branches and applying them to snus, comprising the following steps:

[0026] Step 1. Pretreatment of different types of tobacco: the flue-cured tobacco branches are dried at a low temperature of 40-60°C, more preferably at 50°C, and the Burley tobacco branches and cigar tobacco branches are dried in a ventilated room; In the steps, the temperature of the flue-cured tobacco branch drying refers to the temperature settings of the three stages of the initial curing of the flue-cured tobacco, that is, the yellowing period, the color-fixing period, and the drying period, simulating the conditions of the initial curing of the flue-cured tobacco and the preparation of burley tobacco and cigars. Promote the formation of aroma substances in raw materials. This step may also include links such as screening out foreign matter in the tobacco branches.

[0027] Step 2, sterilizing the pretreated dried tobacco branches with ultravi...

Embodiment 2

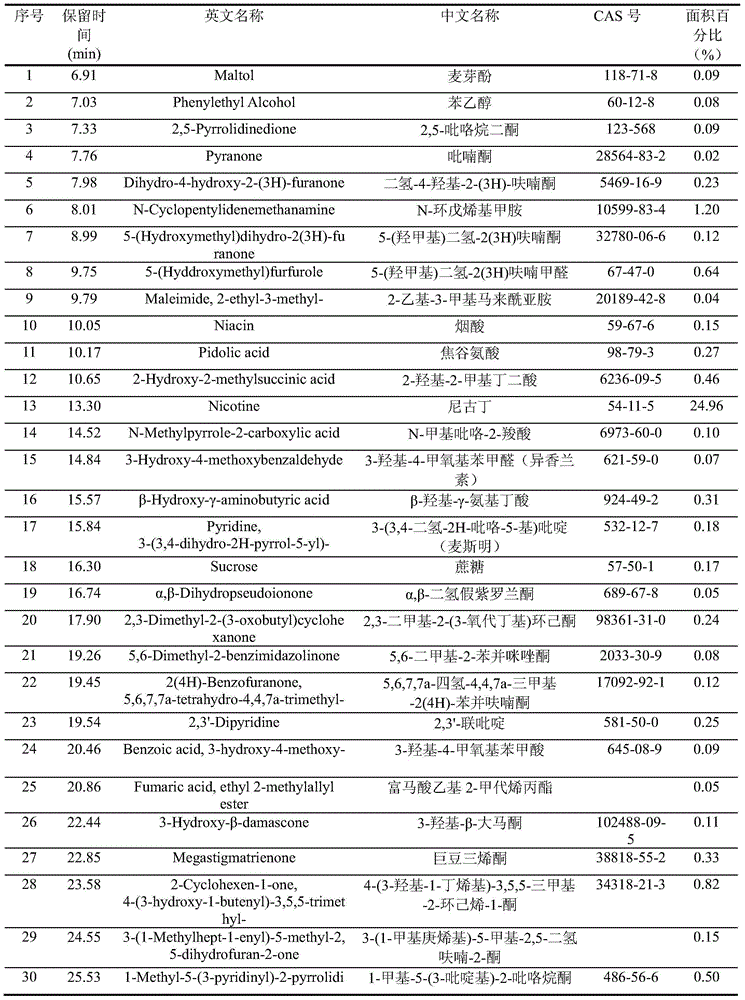

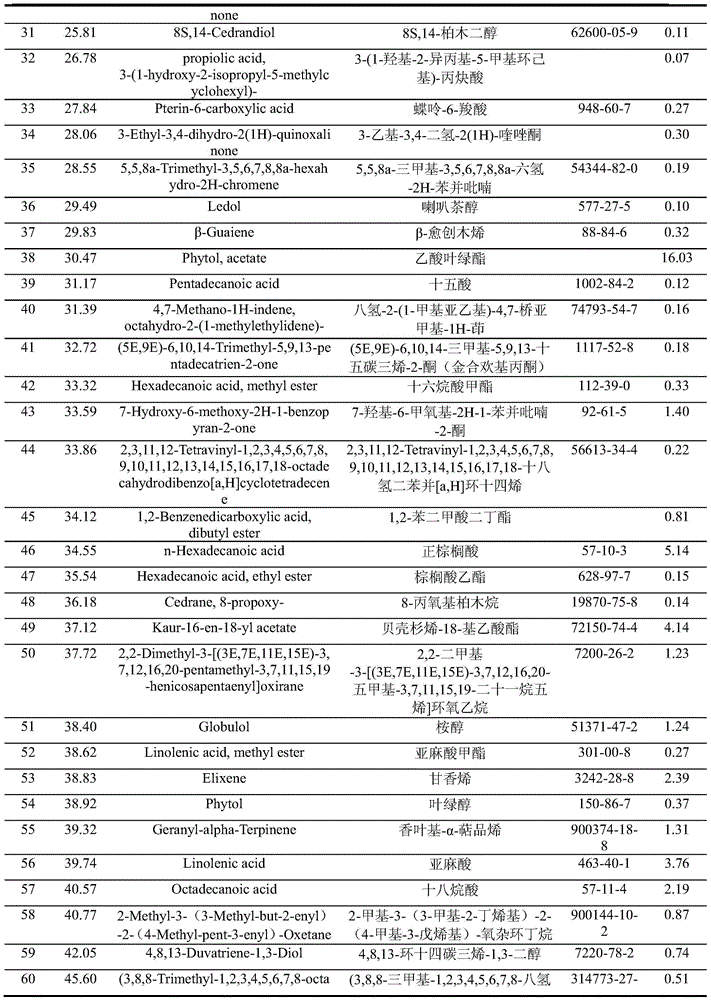

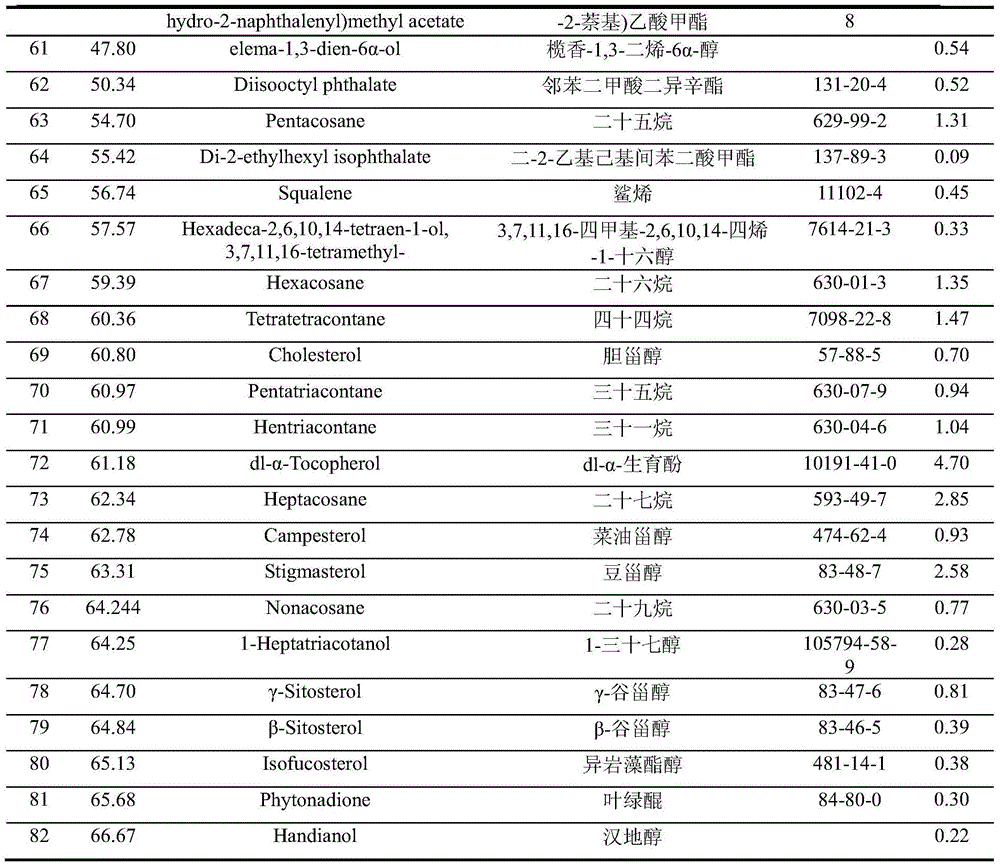

[0035] Collect the flue-cured tobacco smeared by Daejeon, and screen out the foreign matter. Bake at 50°C for 8h, at 30000μW / cm 2 Ultraviolet sterilization for 7s under irradiation intensity, pulverized and selected samples between 20 mesh and 40 mesh sieve. Fill the sample into a supercritical extraction kettle, add 95% ethanol with 10% of the weight of the sample as an entrainer, extract statically for 0.5 h at an extraction temperature of 45 °C and an extraction pressure of 300 bar, and then perform a dynamic extraction for 2 h. The flow rate of carbon dioxide is 2L / min, and the flow rate of 95% ethanol entrainer is 0.5% / min of the sample weight. A dark yellow semi-solid extract was obtained with an extraction rate of 5%. The aroma components of the extract were analyzed, and the results are shown in Table 1.

[0036] Table 1 Analysis results of aroma components of flue-cured tobacco branch SFE extract

[0037]

[0038]

[0039]

[0040] The extract is added to...

Embodiment 3

[0042] Collect the cigar tobacco leaves wiped off by Daejeon, and screen out the foreign matter. Dry overnight in a ventilated room at 50000μW / cm 2Under the irradiation intensity, ultraviolet sterilize for 5s, pulverize and select samples between 10 mesh and 20 mesh sieve. Fill the sample into a supercritical extraction kettle, extract statically for 1 hour under conditions of extraction temperature 40°C and extraction pressure 250 bar, and then perform dynamic extraction for 2 hours. The flow rate of carbon dioxide during dynamic extraction is 1.5 L / min. A light yellow semi-solid extract was obtained with an extraction rate of 2%. The extracts were analyzed for aroma components, and the results are shown in Table 2.

[0043] Table 2 Analysis results of aroma components of SFE extract from cigar tobacco

[0044]

[0045] The extract is added to the snus at a weight ratio of 0.1%, and a qualified cigar-type snus product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radiation intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com