Chinese style pipe tobacco preparation process method

A production process and technology of pipe shreds, which are applied in the fields of tobacco, tobacco preparation, and tobacco treatment, can solve the problems of pipe shreds not conforming to the taste of smoking, poor quality of finished pipe shreds, and extensive and simple preparation methods, so as to achieve simple manufacturing process Controllable, better suction taste, sweet and comfortable taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

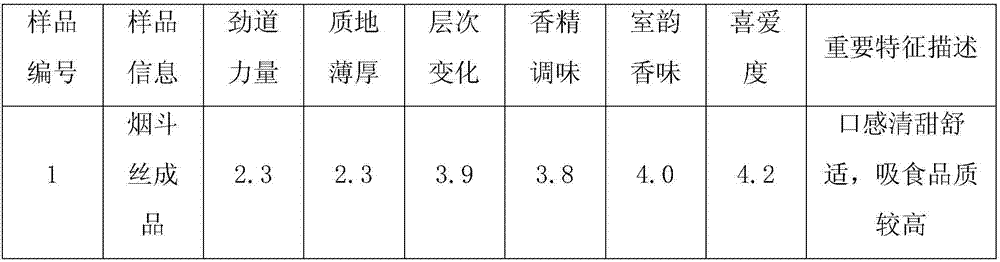

Examples

Embodiment

[0030] A Chinese-style pipe silk manufacturing process, the method is as follows:

[0031] A. Prepare black tobacco shreds: prepare black tobacco leaf mixture according to the following percentage components: 75% tobacco stems, 10% burley tobacco leaves, 6% oriental tobacco leaves, 9% sun-cured tobacco leaves, and add materials to the black tobacco mixture Liquid A, the material liquid A is a mixture of licorice extract, propylene glycol, cocoa essence, firework essential oil, and invert sugar; the preparation method of black smoke tobacco is as follows:

[0032] A1. After uniformly mixing the prepared black tobacco leaf mixture, cut the tobacco leaves into shreds with a shredder to obtain a black smoke tobacco mixture. The cutting width of the tobacco leaves in the black tobacco leaf mixture by the shredder is 2.0 mm;

[0033] A2. Use a sprayer to spray the cut tobacco of the black tobacco cut mixture in step A1 and add liquid A;

[0034] A3. Put the black tobacco shredded tobacco mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com