Perfume material of heating incombustible cigarette perfume producing section of pipe tobacco style and its preparation method

A heat-not-burn, raw material technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problem that the overall flavor of the product cannot meet people's requirements, and achieve the effect of improving the effect, the method is simple and easy, and the effect of improving the flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

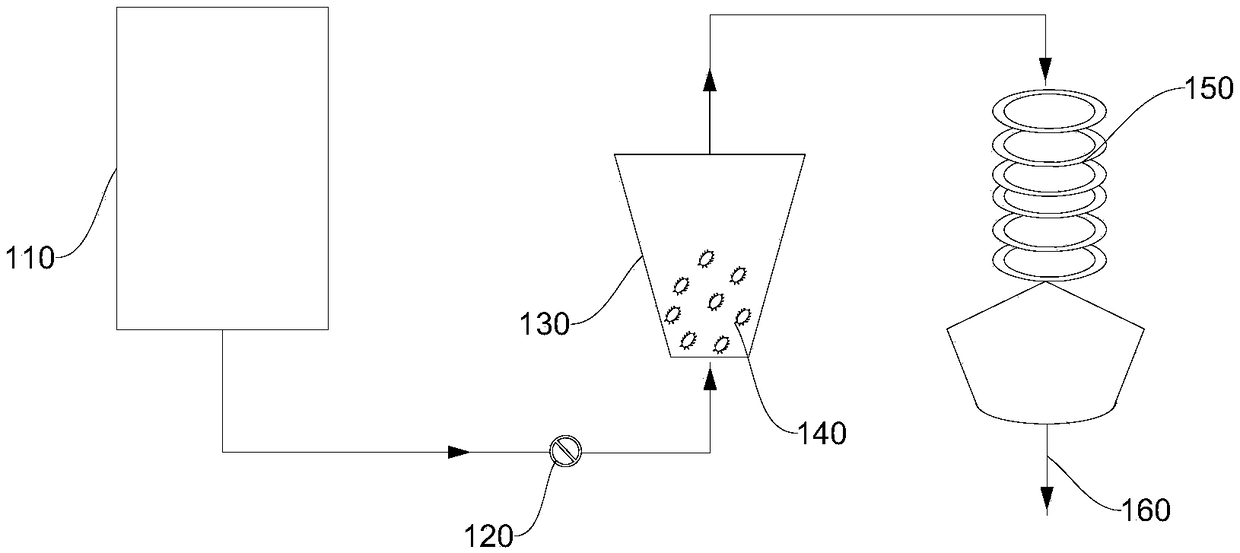

[0031] The embodiment of the present invention also provides a method for preparing an aroma raw material used for the aroma producing segment of pipe tobacco style heat-not-burn cigarettes, comprising the following steps:

[0032] S1. Pulverize the base aroma module, aroma enhancement module, concentration module, mouthfeel module, strength module and flavor module and mix them evenly to obtain a mixed extract.

[0033] Specifically, the following steps are included in the preparation process of the mixed extract: after the above-mentioned aroma raw materials are crushed to 20-40 mesh, they are added to a pretreatment device for pretreatment. The temperature of the pretreatment is 100-200 ° C, and the moisture content of the tobacco leaves It is 15%-25%, and the processing time is 8-24h.

[0034] The pretreatment process makes the ingredients of each module fully fused and undergoes Maillard reaction, increasing the flavor and taste of the aroma raw materials. Therefore, dur...

Embodiment 1

[0041] This embodiment provides an aroma raw material used for the aroma production section of pipe tobacco style heat-not-burn cigarettes. In parts by weight, the above-mentioned aroma raw material includes 30 parts of the base aroma module, 10 parts of the aroma module, 3 parts of the concentration module, and a mouthfeel 1 module, 1 strength module and 1 flavor module; among them, the base fragrance module includes 15 parts of air-cured tobacco and 15 parts of oriental tobacco; the flavor module is vanillin; the concentration module is air-dried tobacco leaves; the taste module includes 0.5 parts of jujube and Luo Han Guo 0.5 parts; the strength module is Burley tobacco; the flavor module includes 0.5 parts of cocoa and 0.5 parts of L-lysine.

[0042] This embodiment also provides a method for preparing an aroma raw material used in the aroma producing segment of pipe tobacco style heat-not-burn cigarettes, which includes the following steps:

[0043] Firstly, after crushin...

Embodiment 2

[0047] This embodiment provides a flavor raw material for pipe tobacco style heat-not-burn cigarette aroma producing segment, in parts by weight, the flavor raw material includes 90 parts of the base flavor module, 40 parts of the flavor enhancement module, 15 parts of the concentration module, taste 8 modules, 8 strength modules, and 8 flavor modules; among them, the base fragrance module includes 60 parts of air-cured tobacco and 30 parts of tobacco stems; the aroma-enhancing module includes 20 parts of rose essential oil and 20 parts of coumarin; the concentration module is air-dried tobacco leaves; The taste module includes 5 parts of jujube and 3 parts of licorice; the strength module is air-cured tobacco; the flavor module includes 4 parts of coffee and 4 parts of L-lysine.

[0048] This embodiment also provides a method for preparing an aroma raw material used in the aroma producing segment of pipe tobacco style heat-not-burn cigarettes, which includes the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com