Tobacco moistening agent and application thereof

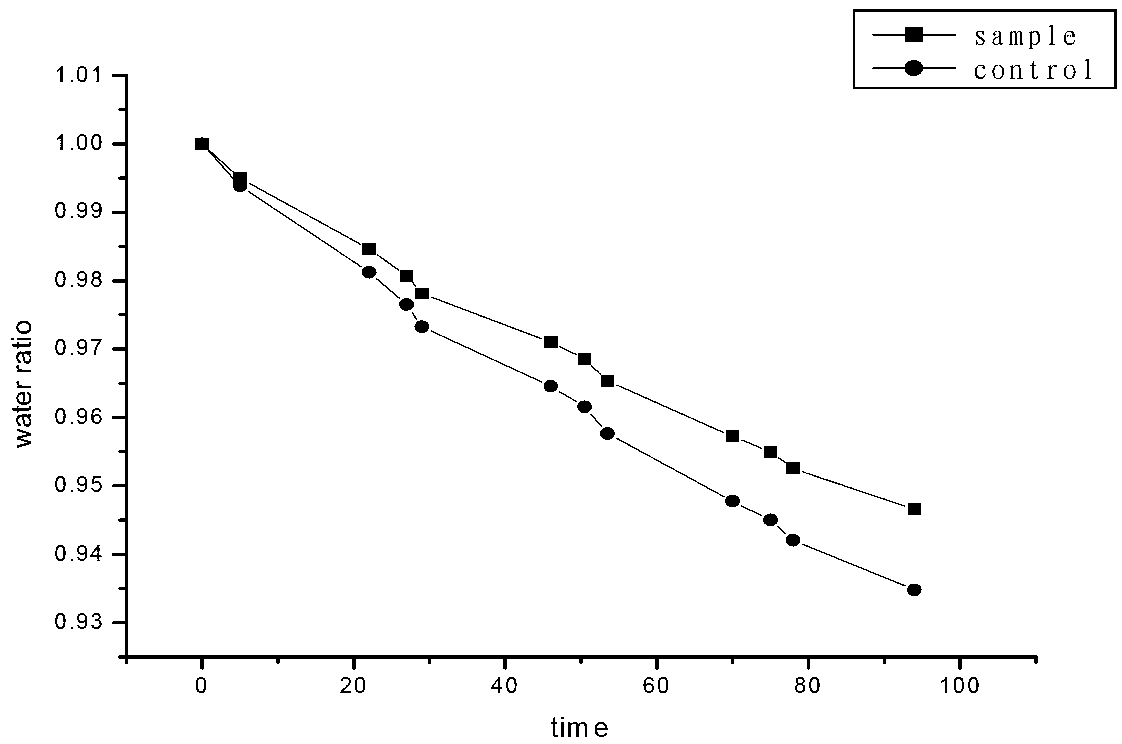

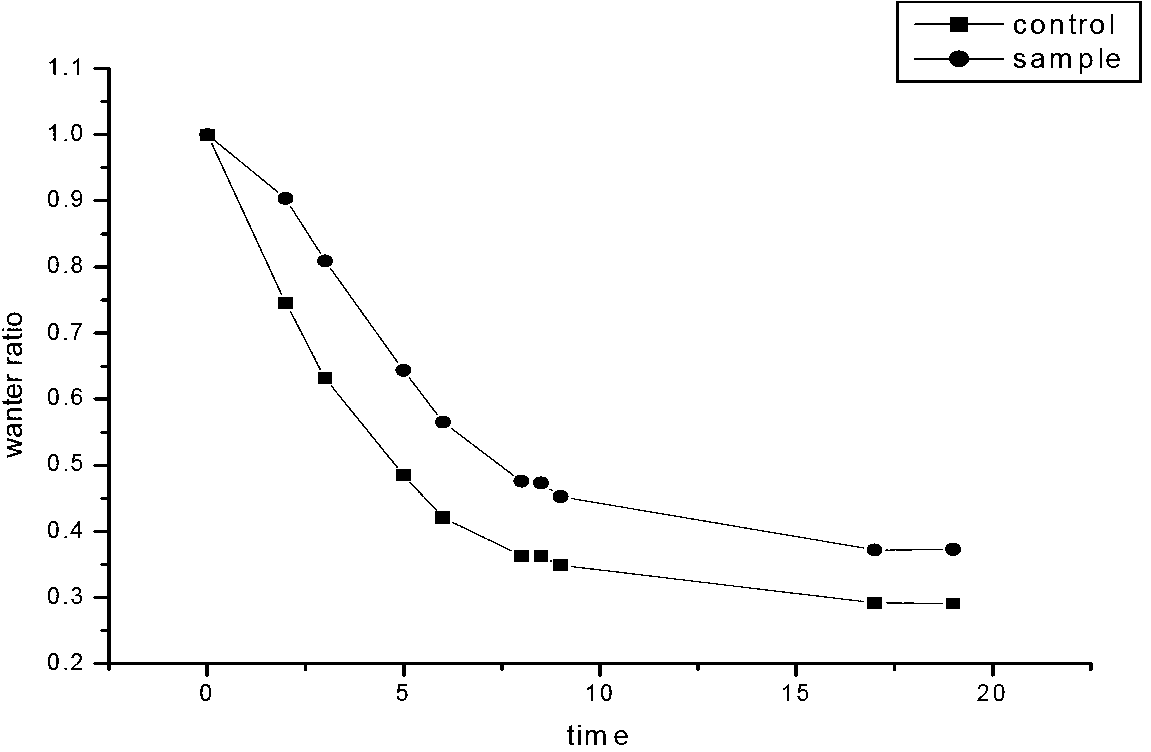

A moisturizing agent and tobacco technology, applied in the fields of tobacco, application, and treatment of tobacco, can solve the problems of moisturizing performance not as good as glycerin and propylene glycol, increased cost of cigarettes, bad taste, etc., to achieve moisture retention, smoldering The effect of good firepower and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

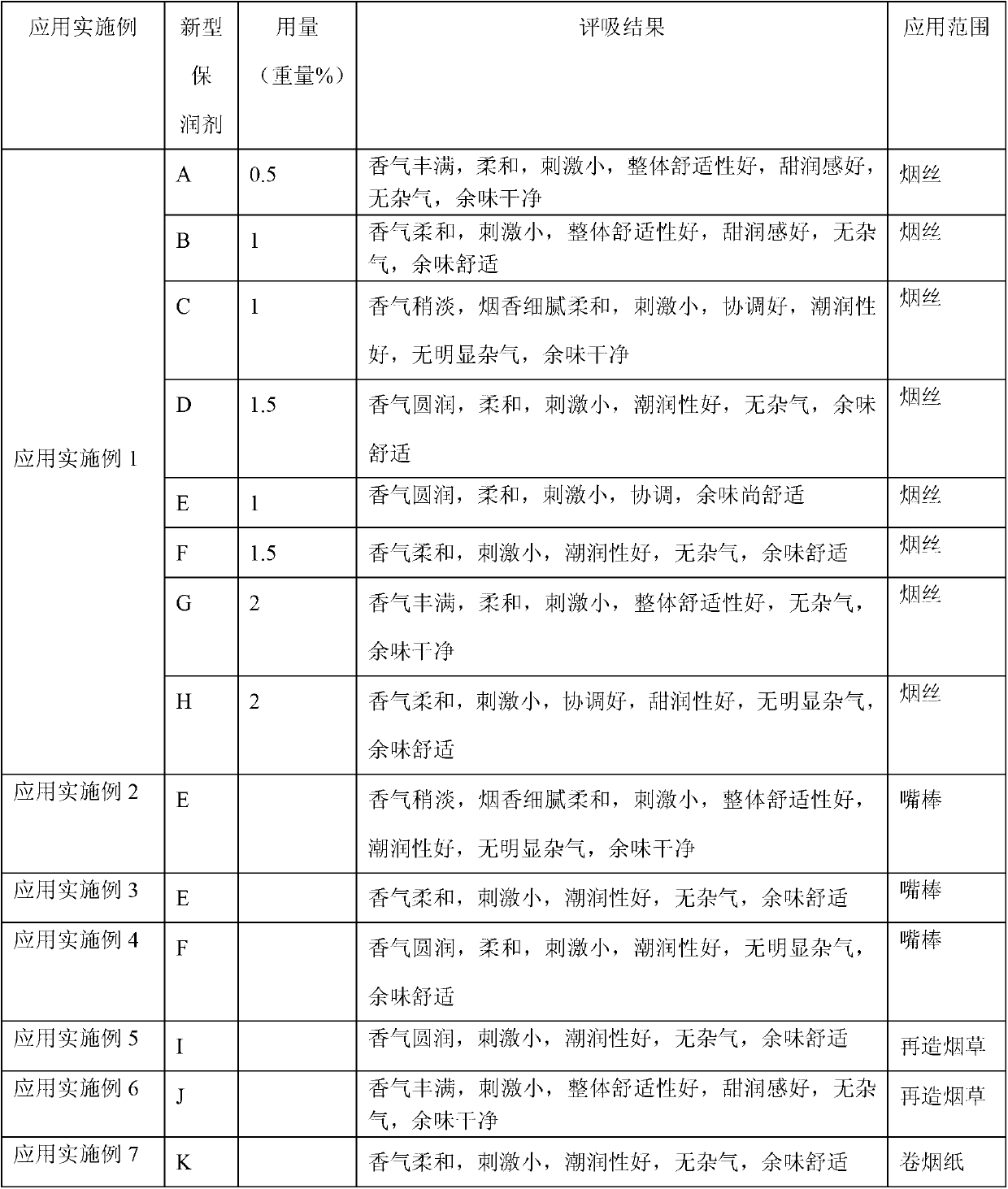

Examples

Embodiment 1

[0027] Dissolve 4.8g of potassium malate, 4.3g of potassium citrate, and 3.8g of potassium carbonate in 990.3g of ultrapure water, heat and stir at a temperature range of 40-60°C. Take trehalose 1.7g, alginic acid 1.6g; hyaluronic acid 1.9g; aspartic acid 1.7g, proline 1.5g, tyrosine 1.2g; xylitol 2.3g, trimethylolethane 1.8g , mixed evenly, added to the alkali metal salt solution, heated and stirred in the temperature range of 50-70°C, mixed and dissolved evenly to obtain the tobacco humectant A.

Embodiment 2

[0029] Dissolve 3.9g of potassium citrate, 3.2g of potassium lactate, and 2.3g of potassium carbonate in 990.3g of ultrapure water, heat and stir at a temperature range of 40-60°C. Take trehalose 1.7g, sulfated polysaccharide 1.7g; aloe vera gel 2.5g; aspartic acid 1.7g, glutamic acid 1.5g, lysine 1.2g; xylitol 2.3g, sorbitol 1.8g, mix well Add it into the alkali metal salt solution, heat and stir in the temperature range of 50-70°C, mix and dissolve evenly to obtain the tobacco humectant B.

Embodiment 3

[0031] Dissolve 3.0 g of potassium malate, 3.0 g of potassium lactate, and 3.0 g of potassium molybdate in 990.3 g of ultrapure water, heat and stir at a temperature range of 40-60°C. Take trehalose 2.1g, fucoidan 1.6g; loofah water 2.7g; aspartic acid 1.7g, tyrosine 1.5g, glutamic acid 1.2g; xylitol 2.6g, pentaerythritol 2.0g, mix well and add to In the alkali metal salt solution, heat and stir in the temperature range of 50-70° C., mix and dissolve evenly to obtain the tobacco humectant C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com