Process for preparing magnetic resonance visibility strengthened film based on layered assembly technology

A technology of magnetic resonance visibility and layered assembly, applied in coatings, medical science, diagnosis, etc., can solve problems such as the difficulty of modifying magnetic nanoparticles, and achieve the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the preparation of polymer microgel

[0051] Add 1 mL of chromium trioxide aqueous solution (5 mg / mL) to 4 mL of hyaluronic acid (HA) aqueous solution (concentration: 40 mg / mL), and stir for 12 hours at room temperature in the dark. Then 10 mL of polyvinylimine (PEI) aqueous solution (concentration of 40 mg / mL) was added thereto, and sodium hydroxide was gradually added to the solution until the pH value was 10 (use a pH meter to detect the pH value of the solution). At this time, the aldehyde groups obtained after hyaluronic acid oxidation will directly chemically cross-link with the amino groups of polyvinylimine in aqueous solution to form polyvinylimine-hyaluronic acid microgels (PEI-H microgels). The product PEI-H microgels aqueous solution was dialyzed for three days using a dialysis bag with a cut-off molecular weight of 8000 to remove impurity ions (impurity ions include: sodium ions, chromium ions, etc.), and diluted to 100mL with deionized water ...

Embodiment 2

[0054] Embodiment 2: Preparation of microgel containing ferric oxide nanoparticles

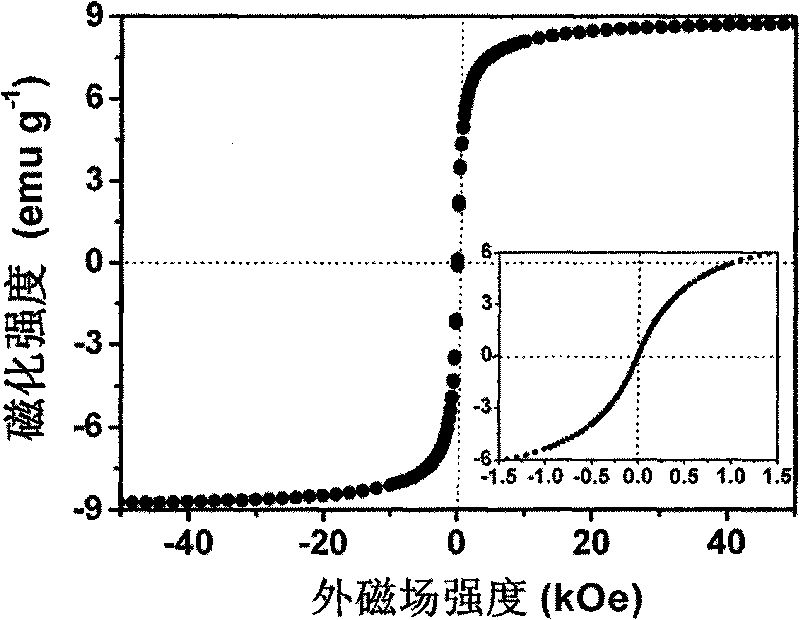

[0055] Mix 0.016g ferric chloride (0.1mmol), 0.0064g ferric chloride (0.05mmol) and the polyvinylimine-hyaluronic acid microgel (5.6mg / mL) that 10mL embodiment 1 prepares, stir 20min . Add 0.5mL ammonia water (14mol / L) to the above mixture for hydrolysis, and continue stirring for 10min to obtain a uniform black magnetic microgel aqueous solution (Fe 3 o 4 @PEI-H microgels). The concentration of the synthesized magnetic microgel aqueous solution is 6.8mg / mL, and the mass content of ferric iron tetroxide nanoparticles in the magnetic microgel is 17%. Nitrogen protection was always used during the reaction. The solution must be sealed and stored at 4°C. Such as figure 1 As shown, Fe 3 o 4 @PEI-H microgels do not show magnetism when the external magnetic field is zero, and show magnetism when the external magnetic field is not zero, so the microgel containing ferroferric oxide nanoparticl...

Embodiment 3

[0059] Example 3: Preparation of microgel multilayer film containing ferric oxide nanoparticles

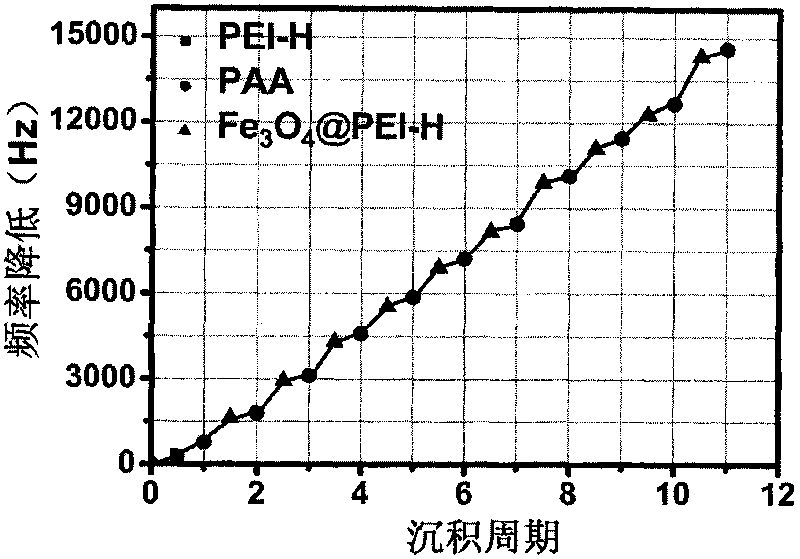

[0060] Precursor film preparation was achieved by soaking polyethylene substrates in PEI-H microgels (1 mg / mL, pH = 10) and polyacrylic acid (PAA) solution (1 mg / mL, pH = 10) for 15 min each. Then alternately soak in Fe 3 o 4@PEI-H microgels (1 mg / mL, pH = 10) and PAA solution (1 mg / mL, pH = 10) for 15 minutes each, repeating this step to obtain a multilayer film containing ferric oxide nanoparticles. After each step of soaking, it is washed with water and N 2 The process of drying. figure 2 The growth process of multilayer films containing Fe3O4 nanoparticles was monitored using a quartz microweight balance. It shows that the multilayer film shows a linear growth trend, that is, the quality of the multilayer film increases linearly with the increase of the deposited layers.

[0061] In this example, the concentrations of PEI-H microgels and PAA solutions are both 1 mg / mL an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com