Gas kitchen ranges burner

A technology for burners and gas stoves, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of low energy consumption and heat efficiency, tempering and popping, unstable combustion, etc., and achieve high thermal efficiency and smoke The effect of low emission and sufficient supplementary air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

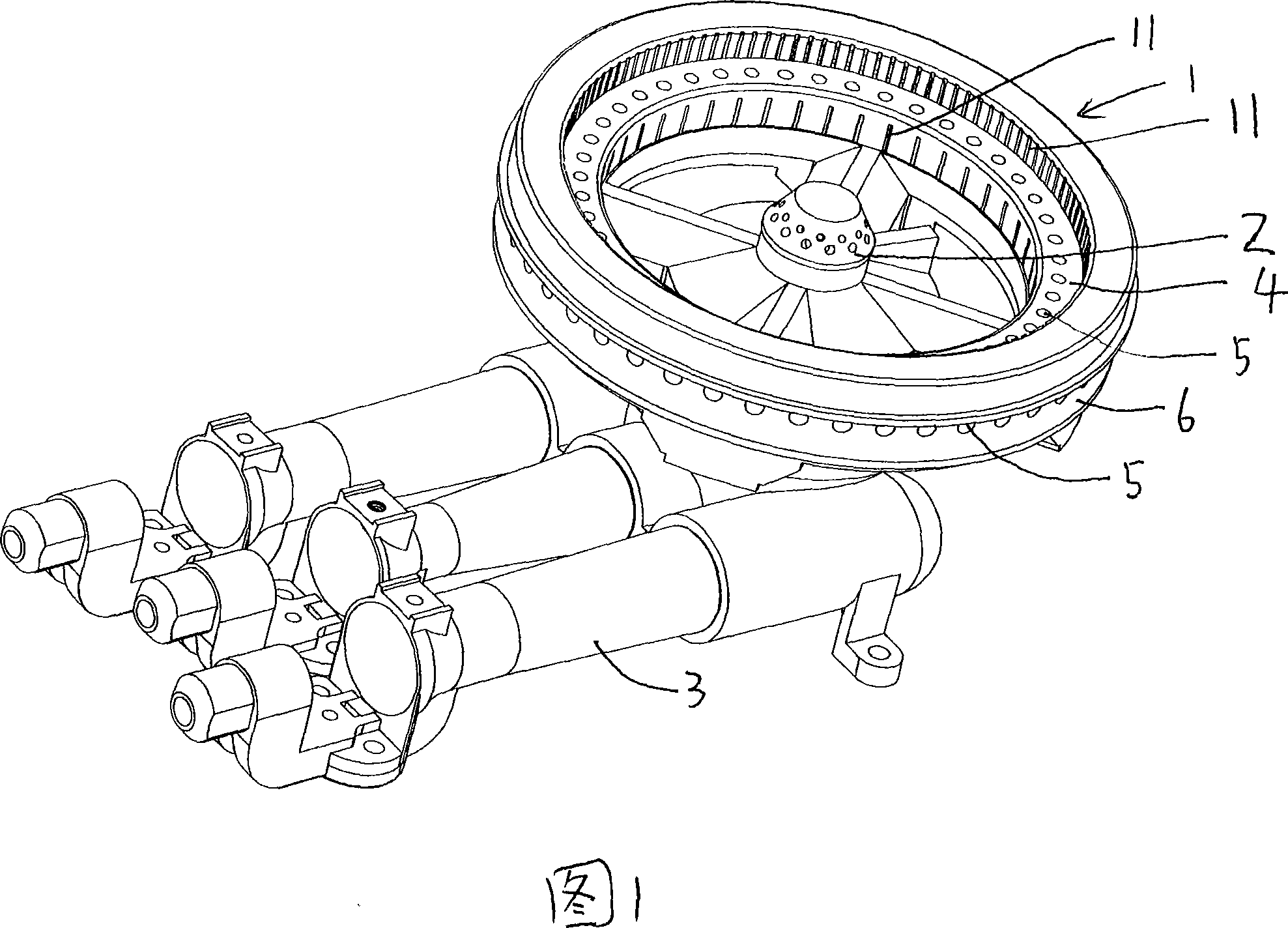

[0011] Embodiment: a gas stove burner, including a fire cover and an ejector tube. The fire cover includes an outer ring fire cover 1 and an inner ring fire cover 2. There are at least two rows of upper and lower rows facing the fire cover on the inside of the outer ring fire cover The outer ring fire hole 11 of the center is provided with three injection pipes 3 at least again, and one of them communicates with the inner ring fire hole on the inner ring fire cover, and the remaining injection pipe communicates with the outer ring fire hole.

[0012] The two rows of outer ring fire holes 11 on the outer ring fire cover are arranged on the inside elevation of the outer ring fire cover. The opening of the ring fire hole is facing the center of the fire cover.

[0013] The shoulder 4 between the two rows of outer ring fire holes is provided with several secondary air intake holes 5, one end of the secondary air intake hole opens upward, and the other end of the secondary air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com