Hydrogen generator and application thereof

A generator and hydrogen technology, applied in hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as adverse effects, increased surface area, and limited improvement effects, and achieve extremely rich economic value, uniform temperature distribution, and good heat transfer The effect of potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: 200 liters / hour hydrogen production test

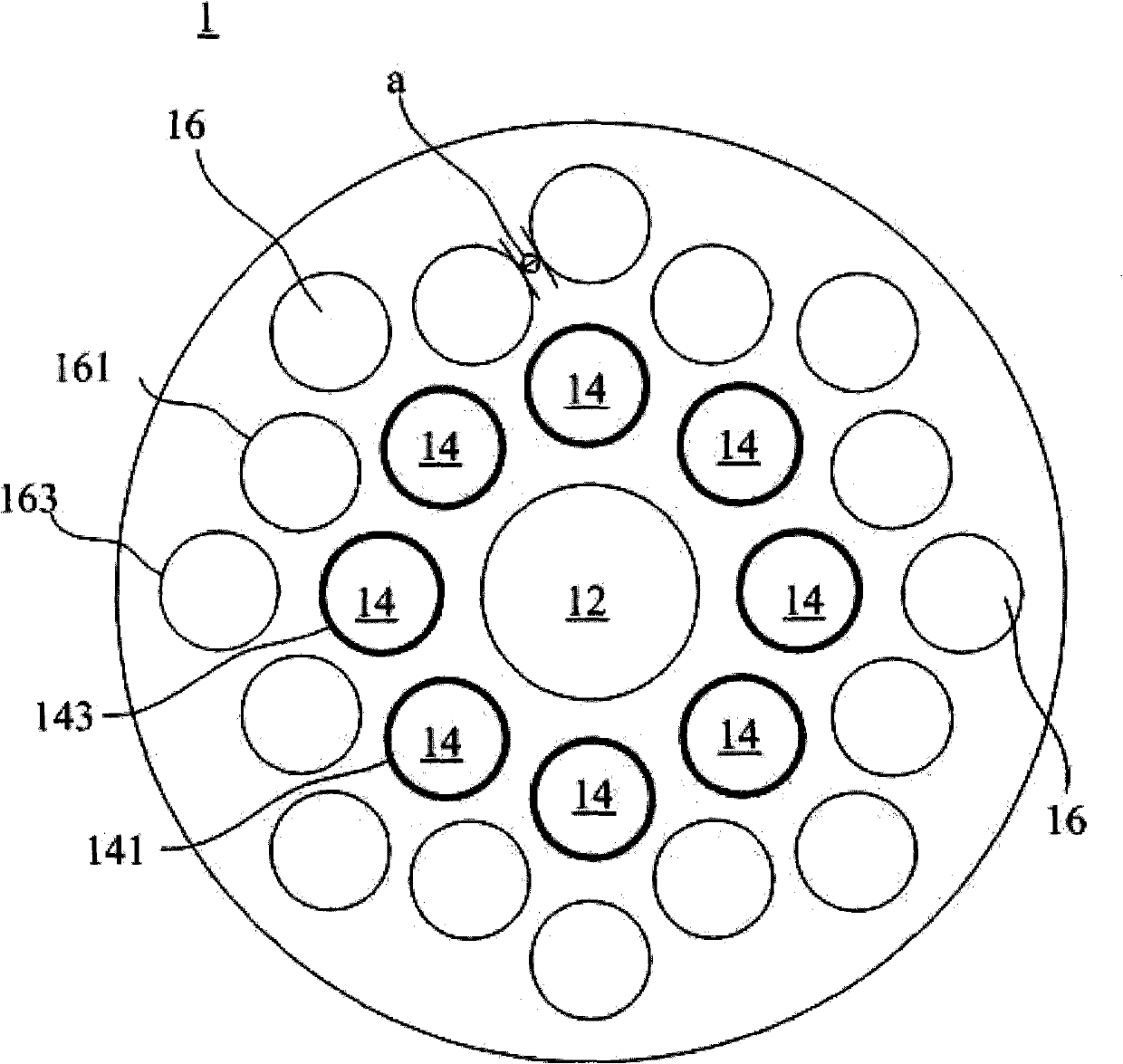

[0060] use as figure 1 In the shown cylindrical hydrogen generator 1, aluminum alloy (AI-6061) is used as the first medium forming the hydrogen generator 1, wherein the diameter of the hydrogen generator 1 is about 51 millimeters, the depth is about 50 millimeters, and each channel The shortest distance a between them is about 1 mm. The diameter of the oxidation zone 12 in the center of the hydrogen generator 1 is about 13 millimeters and the depth is about 50 millimeters, and the PBN oxidation catalyst of about 9 grams is filled in the oxidation zone 12; The diameter of the 8 channels of the preheating zone 14 is about 7 mm and a depth of about 50 mm; the diameter of the 16 channels of the recombination zone 16 is about 7 mm and a depth of about 50 mm, and the channels of the recombination zone 16 are filled with about 43 grams of recombination catalyst JM-51.

[0061] Methanol is used as raw material for hydrogen...

Embodiment 2

[0062] Example 2: 200 liters / hour hydrogen production test

[0063] Carry out methanol vapor recombination reaction with the same hydrogen generator and method as in Example 1. But use brass (70% Cu, 30% Zn, thermal conductivity about 121W / m-K) as the first medium constituting the hydrogen generator 1, and adjust the supply rate of methanol in the fuel so that the hydrogen generation rate reaches 200 liters / hour . Measure the temperature distribution of hydrogen generator 1, calculate the thermal efficiency of hydrogen and total methanol, and analyze the carbon monoxide content in the hydrogen-containing mixed gas obtained, and record the results in Table 1.

Embodiment 4

[0070] Example 4: 200 liters / hour hydrogen production test

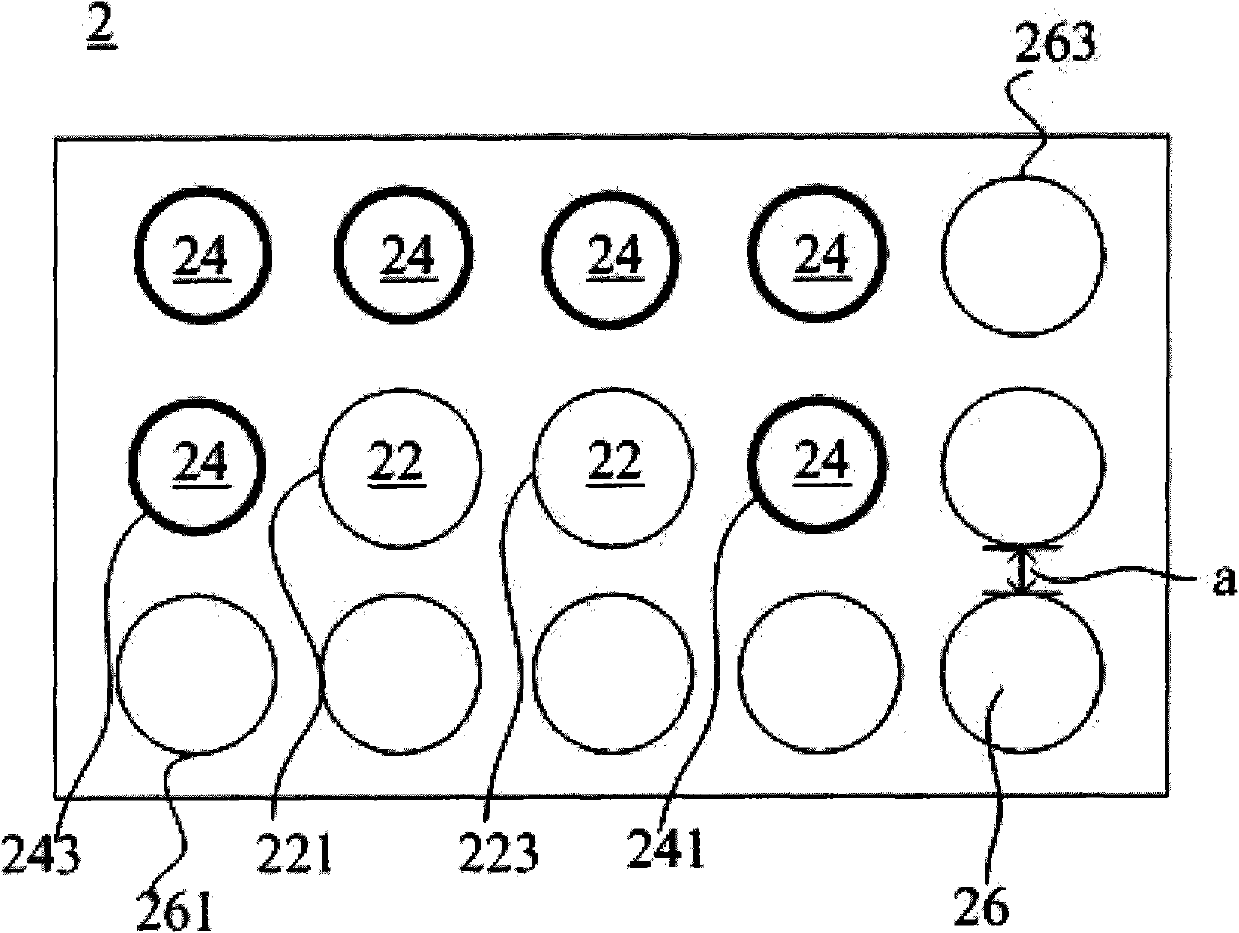

[0071] use as figure 2 The shown rectangular hydrogen generator 2, wherein aluminum alloy (Al-6061) is used as the first medium forming the hydrogen generator 2, wherein the size of the hydrogen generator 2 is about 55 mm × about 34 mm × about 50 mm, And the shortest distance a between the channels is about 1.5 mm. The pore diameter of the oxidation zone 22 of the hydrogen generating device 2 is about 9 millimeters and the depth is about 50 millimeters, and about 4 grams of PBN oxidation catalyst is filled in the oxidation zone 22; the pore diameter of the preheating zone 24 is about 7 millimeters and the depth is About 50 mm; the channel diameter of the recombination zone 26 is about 9 mm and the depth is about 50 mm, and the channel of the recombination zone 26 is filled with about 29 grams of recombination catalyst JM-51.

[0072] Same as Example 1, methanol and water are used as raw materials for hydrogen prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com