High-temperature solid fuel gasification device

A fuel gasification and high-temperature solid technology, which is applied in the manufacture of combustible gas, energy input, petroleum industry, etc., can solve the problems of tar generation, achieve the effects of preventing surface carbon, promoting tar cracking, and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

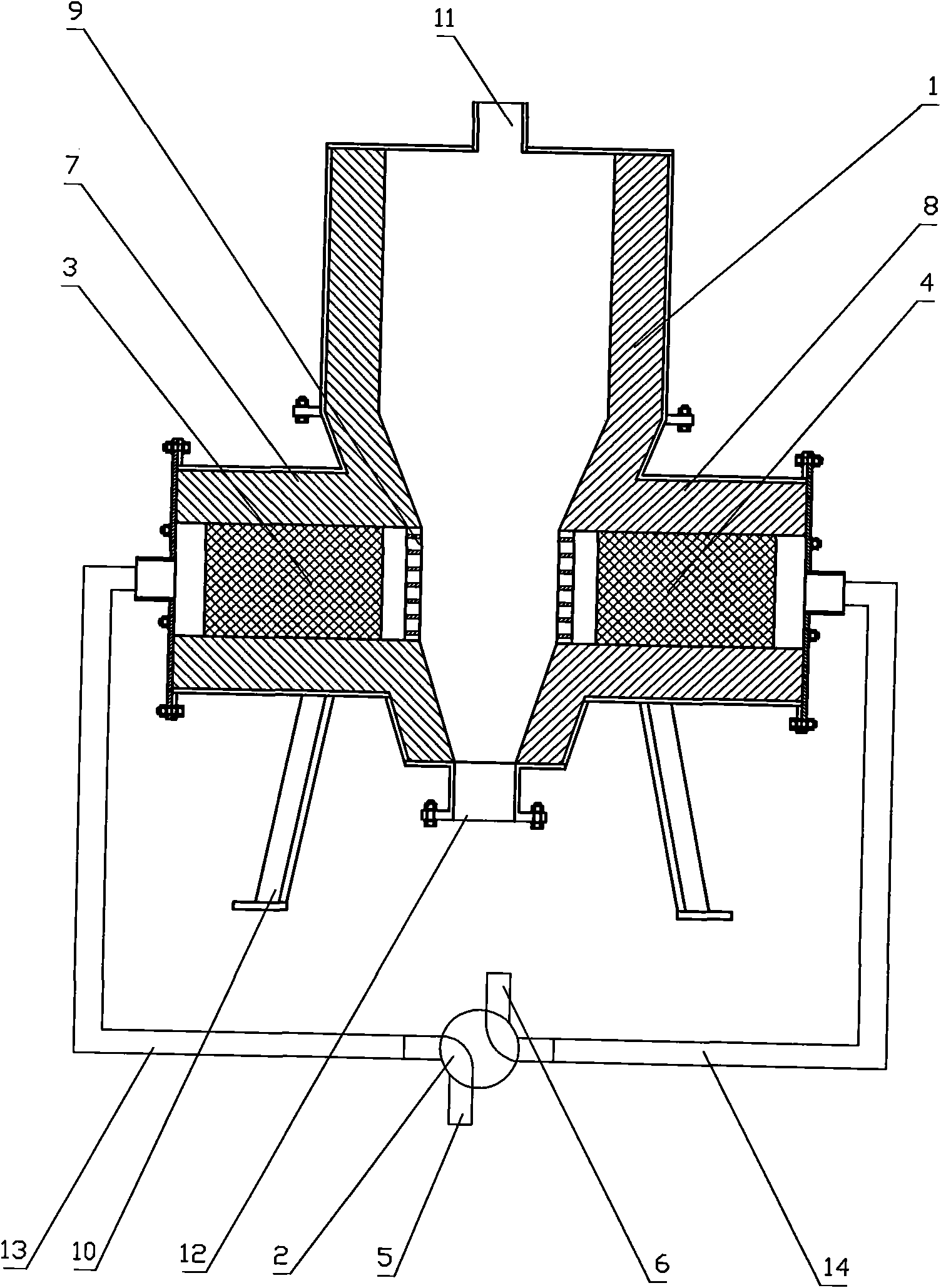

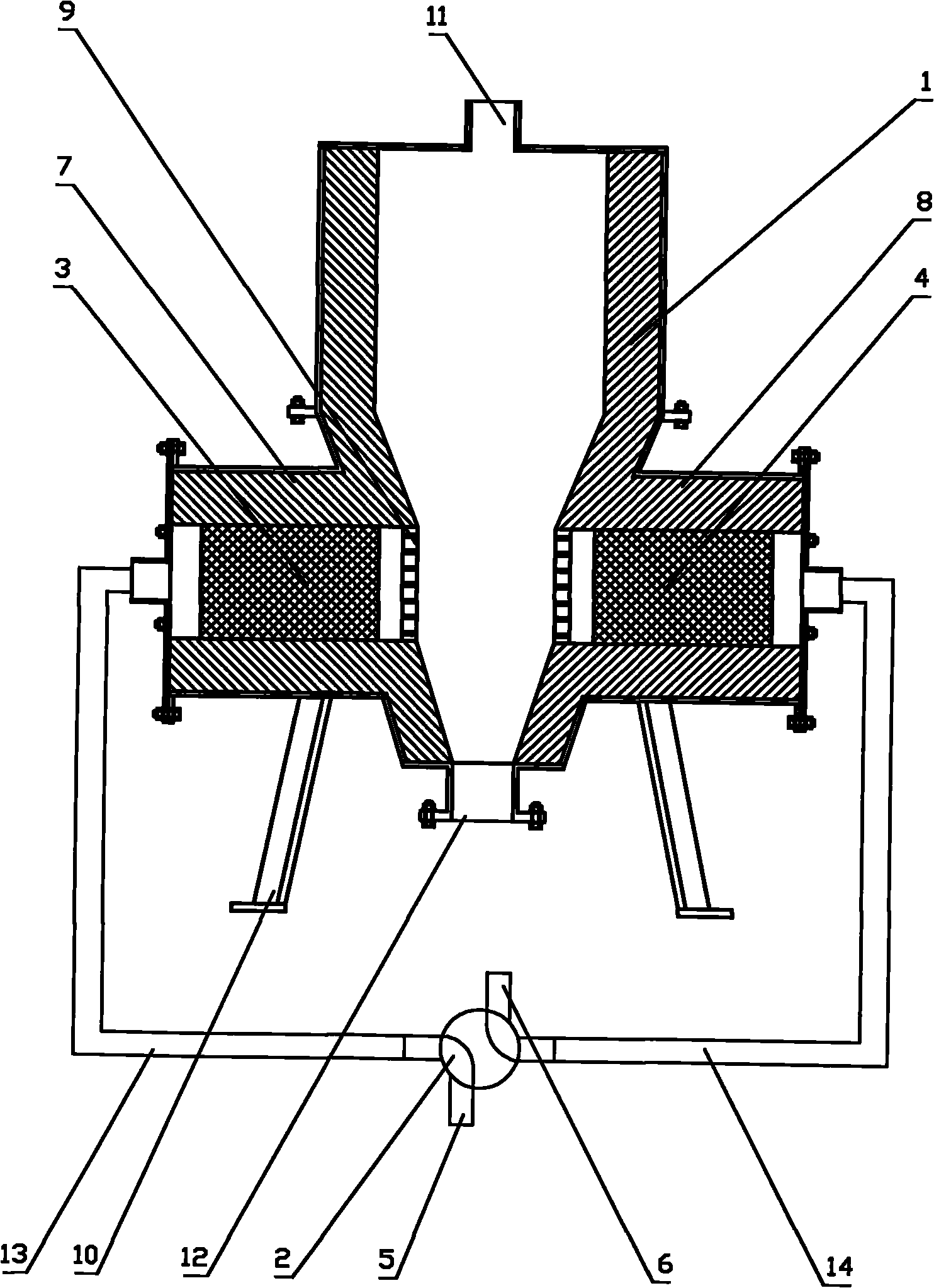

[0018] Accompanying drawing is the sectional view of the present invention, as shown in the figure: high-temperature solid fuel gasification device comprises furnace body 1, four-way switching valve 2, left honeycomb ceramics 3, right honeycomb ceramics 4 and symmetrically arranged at the bottom of furnace body 1 And the left regenerator 7 and the right regenerator 8 of the hollow structure communicated with the furnace body 1 . The furnace body 1 is supported on a bracket 10 , the top of the furnace body 1 is provided with a feed valve 11 , and the bottom is provided with an ash discharge valve 12 . The axes of the hollow holes of the left regenerator 7 and the right regenerator 8 are vertically arranged with the furnace wall of the furnace body 1, the left honeycomb ceramics 3 are arranged in the left regenerator 7, and the right ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com