Mixed flue gas blendedwith air and dimethyl ether and preparation method thereof

A technology of mixing gas and production method, which is applied in the direction of fuel, gas fuel, petroleum industry, etc., can solve the problems of increased transportation cost, difficult pipeline transportation, and large investment, etc., and achieves improvement of residential gas conditions, improvement of kitchen environment, enhancement of safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

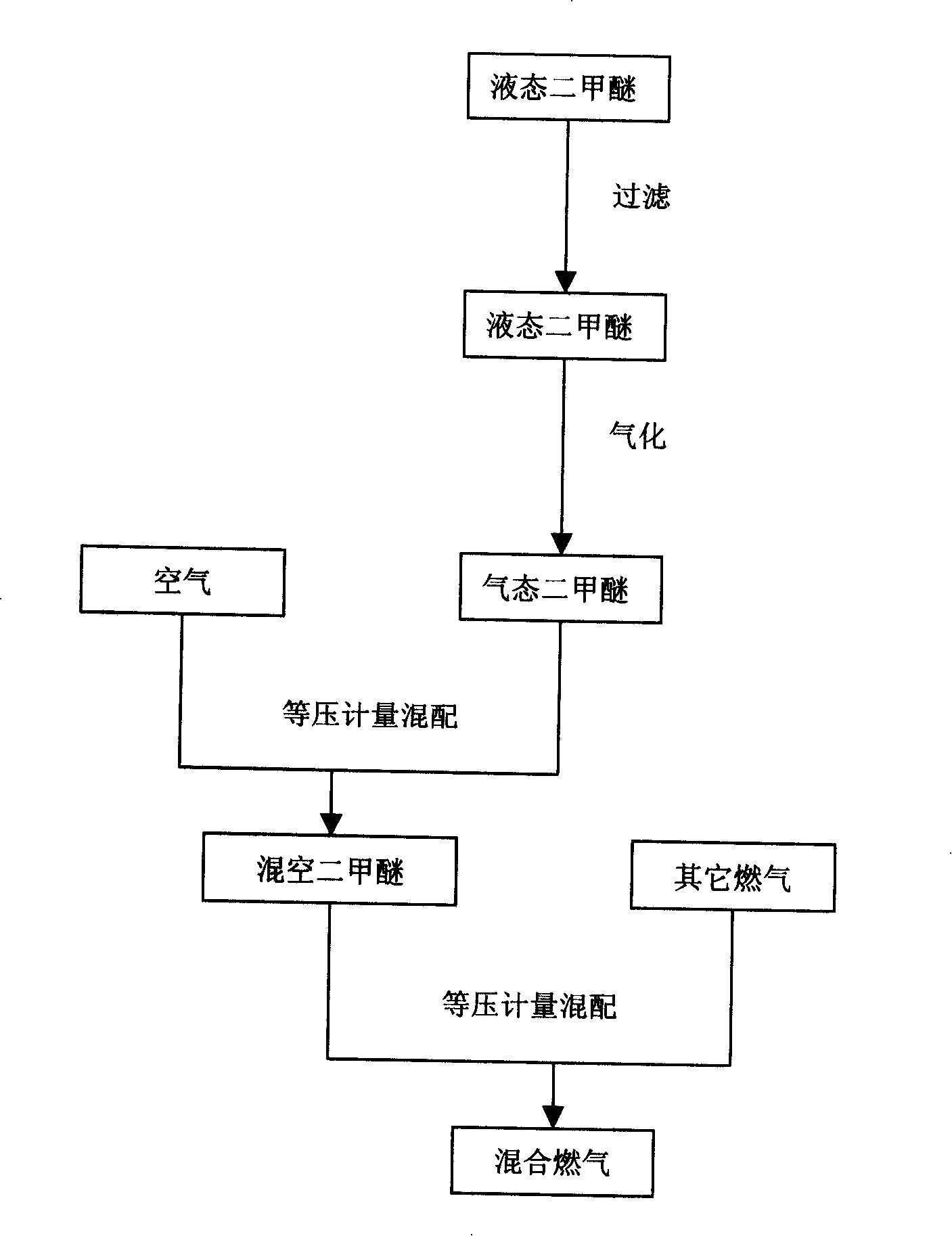

[0035] The basic technological process of the present invention is as figure 1 As shown, the liquid dimethyl ether is firstly filtered to remove impurities, and then the filtered liquid dimethyl ether is introduced into a thermal compensation vaporizer for vaporization, and then the vaporized dimethyl ether is mixed with air at equal pressure to prepare into mixed air dimethyl ether; then the mixed air dimethyl ether is mixed with other gas and other pressure metering to prepare the mixed gas of the present invention. Table 1 has listed 40 specific embodiments of the mixed gas made according to the above method, wherein the mixed gas of embodiment 1-7 meets the 5R city gas standard (Wobai index W is 21.1-24.3MJ / m 3 , combustion potential CP is 55-96); the mixed gas of embodiment 8-18 meets the gas standard of 5R artificial gas (Wobai index W is 21.1-24.3MJ / m 3 , combustion potential CP is 55-96); the mixed gas of embodiment 19-32 meets the gas standard of 6T natural gas; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com