Method for preparing quicklime by continuously calcining limestone in shaft kiln

A technology for calcining limestone and quicklime, applied in lime production and other directions, can solve the problems of difficult to guarantee product quality, high production cost, unstable operating conditions, etc., and achieve the effects of improving product quality, saving fossil fuels and lowering production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

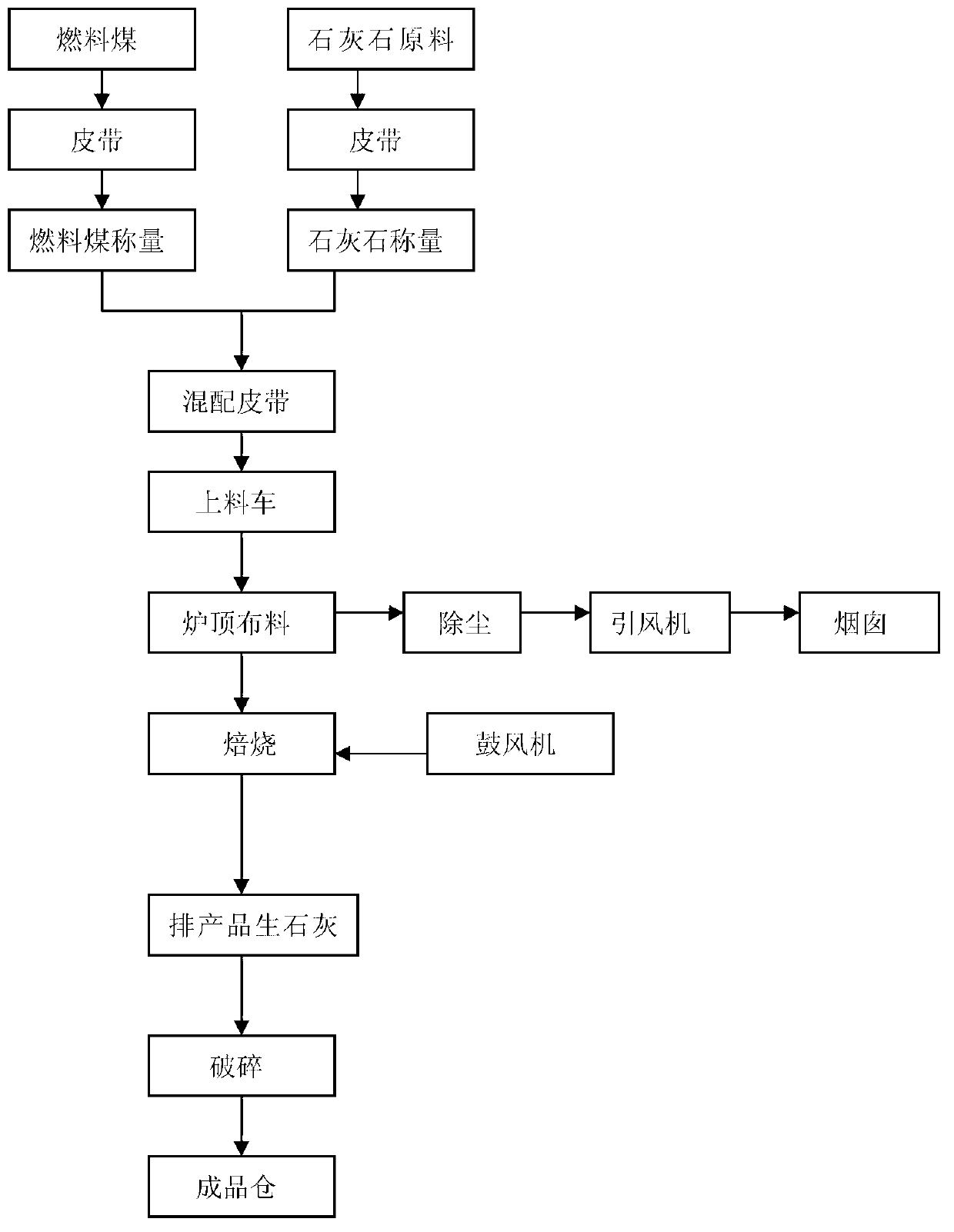

[0041] The quicklime product of the present invention is prepared according to the following methods and steps

[0042] Equipped with a computer centralized control system, through the preset program, the following operations are realized:

[0043] ①. The gas flow and pressure of the furnace bottom combustion air blast and the furnace top exhaust air are automatically controlled, and the continuous calcination is performed;

[0044] ②. Periodic intermittent automatic discharge of calcined qualified product quicklime

[0045] ③. The raw material limestone and fuel coal shall be mixed uniformly according to the proposed ratio, synchronized with the discharged products, and automatically replenished periodically and intermittently;

[0046] It includes the following steps:

[0047] a. Original driving

[0048] Qualified raw material limestone and fuel coal are automatically measured, conveyed and fed to the set height, ignited, and calcined until the quicklime product is quali...

Embodiment 2

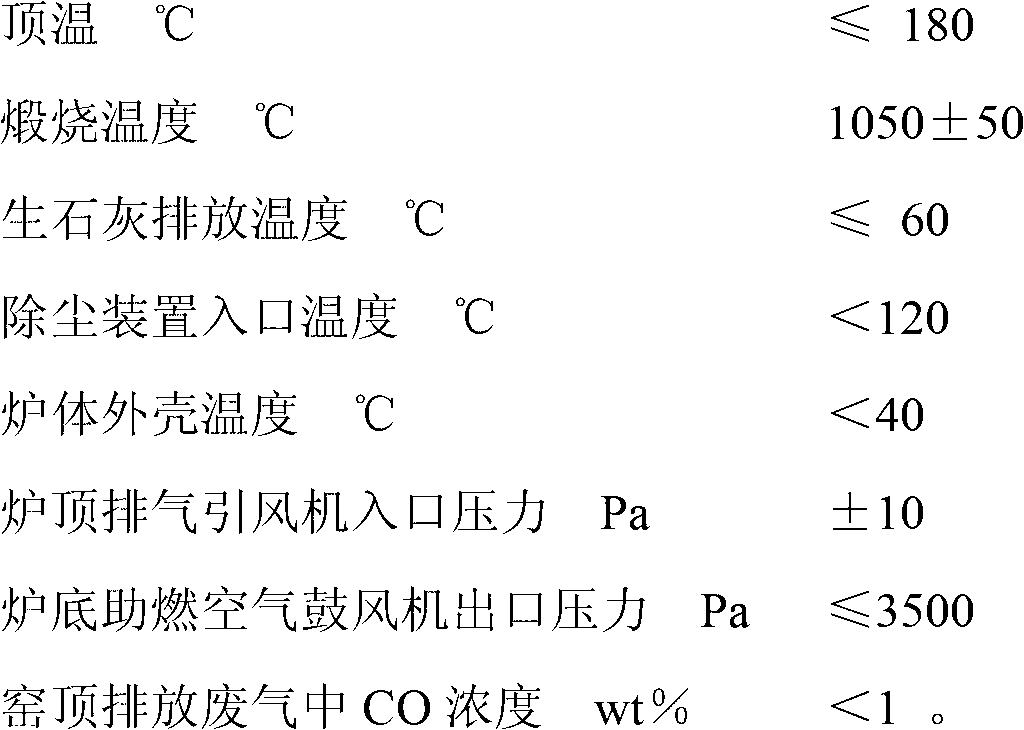

[0055] Prepare the quicklime product of the present invention according to the method and steps of Example 1

[0056] Other technical indicators are as follows:

[0057]

[0058]

[0059] The thermal efficiency of fuel coal is 90%. Product Quicklime Quality Index CaO≥94%, MgO≤3%, SiO 2 ≤1.5%, reduced by ≤10%. 115 kg of fuel coal is consumed per ton of product quicklime.

Embodiment 3

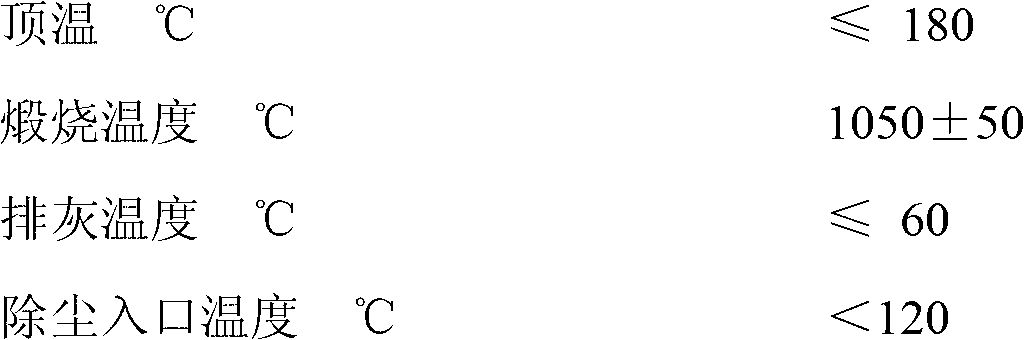

[0061] Prepare the quicklime product of the present invention according to the method and steps of Example 1

[0062] Other technical indicators are as follows:

[0063]

[0064] The thermal efficiency of fuel coal is 85%. Product Quicklime Quality Index CaO≥90%, MgO≤4%, SiO 2 ≤2%, reduce ≤10%. Each ton of product quicklime consumes 120 kilograms of fuel coal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com