Cigarette formula grouped designing and processing method

A processing method and formula technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problem of not fundamentally improving the formula, reduce the amount of tar in the product and the amount of carbon monoxide in the flue gas, have strong flexibility, and improve the utilization rate of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

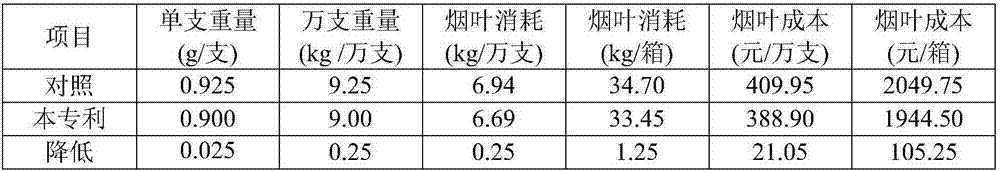

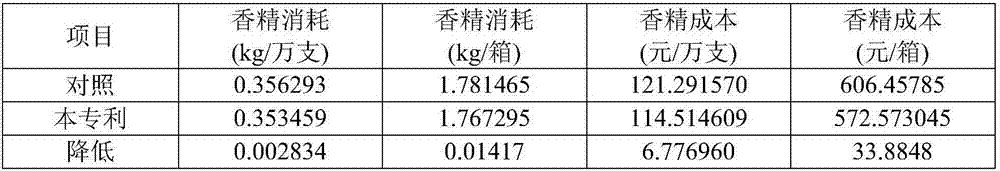

[0017] Embodiment: Group design and processing method of A brand cigarette formula

[0018] 1. Production process:

[0019] 1) Screening of auxiliary formula raw materials: According to the improvement needs of product formula design, several kinds of tobacco leaf raw materials are selected, and air-flow drying and tube-sheet drying tests are carried out respectively, and several kinds of tobacco leaf raw materials suitable for air-flow drying process are initially selected for use.

[0020] 2) Auxiliary formula composition design: carry out formula composition experimental design on the primary selected tobacco leaf raw materials to form an auxiliary formula, which is composed of 20 types of tobacco leaves in different proportions.

[0021] 3) Auxiliary formula material liquid design: Combined with the quality characteristics of the auxiliary formula, the material liquid formula is designed. The material liquid formula is composed of 3 kinds of material bases and 3 kinds of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com