Manufacture method of bi-distributed feedback laser double-amplifier based on gamma waveguide

A manufacturing method and double-distribution technology, applied in the direction of semiconductor lasers, semiconductor laser devices, lasers, etc., can solve problems such as the inability to take into account the depth of signal modulation and the reduction of signal tuning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

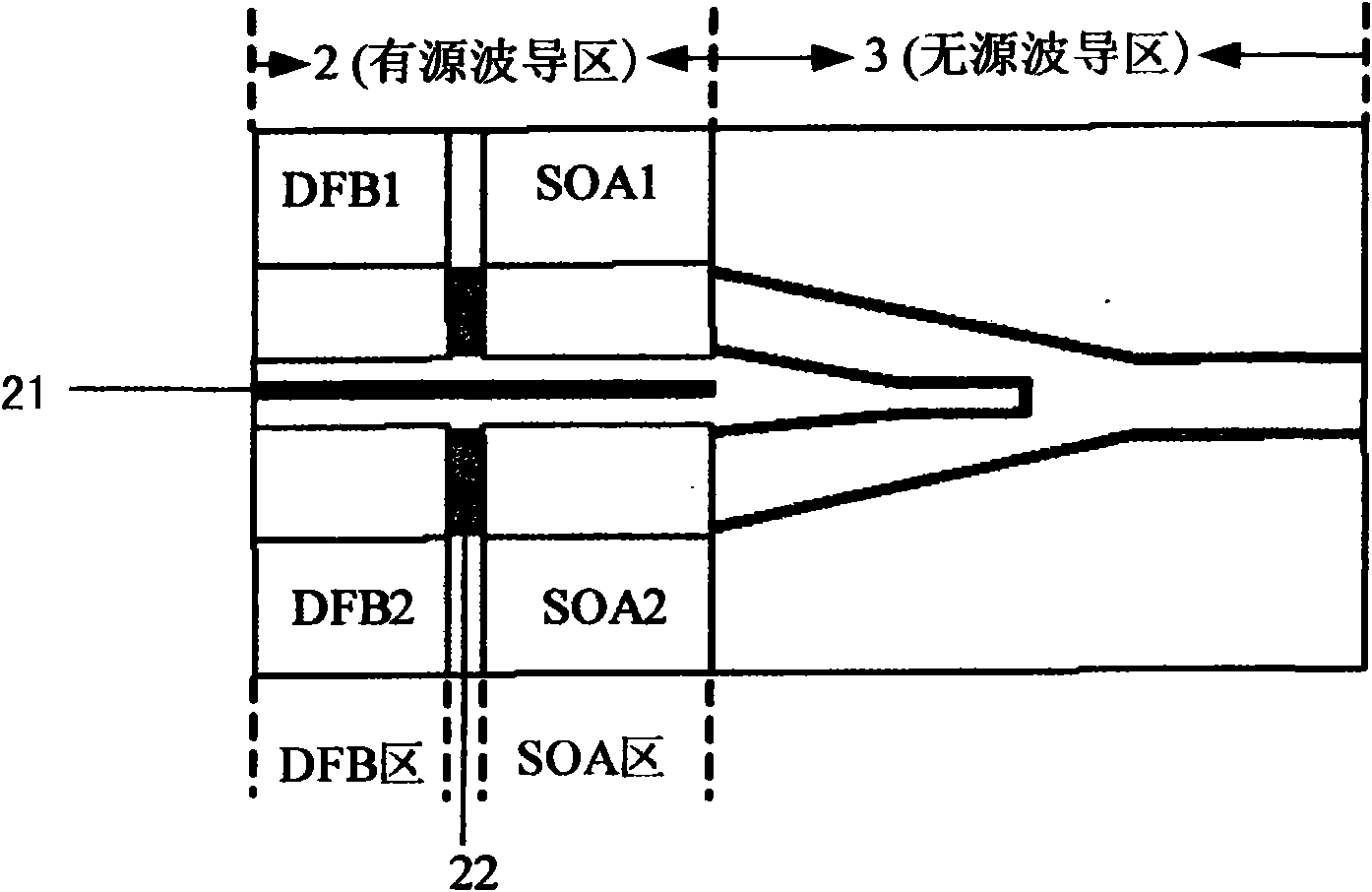

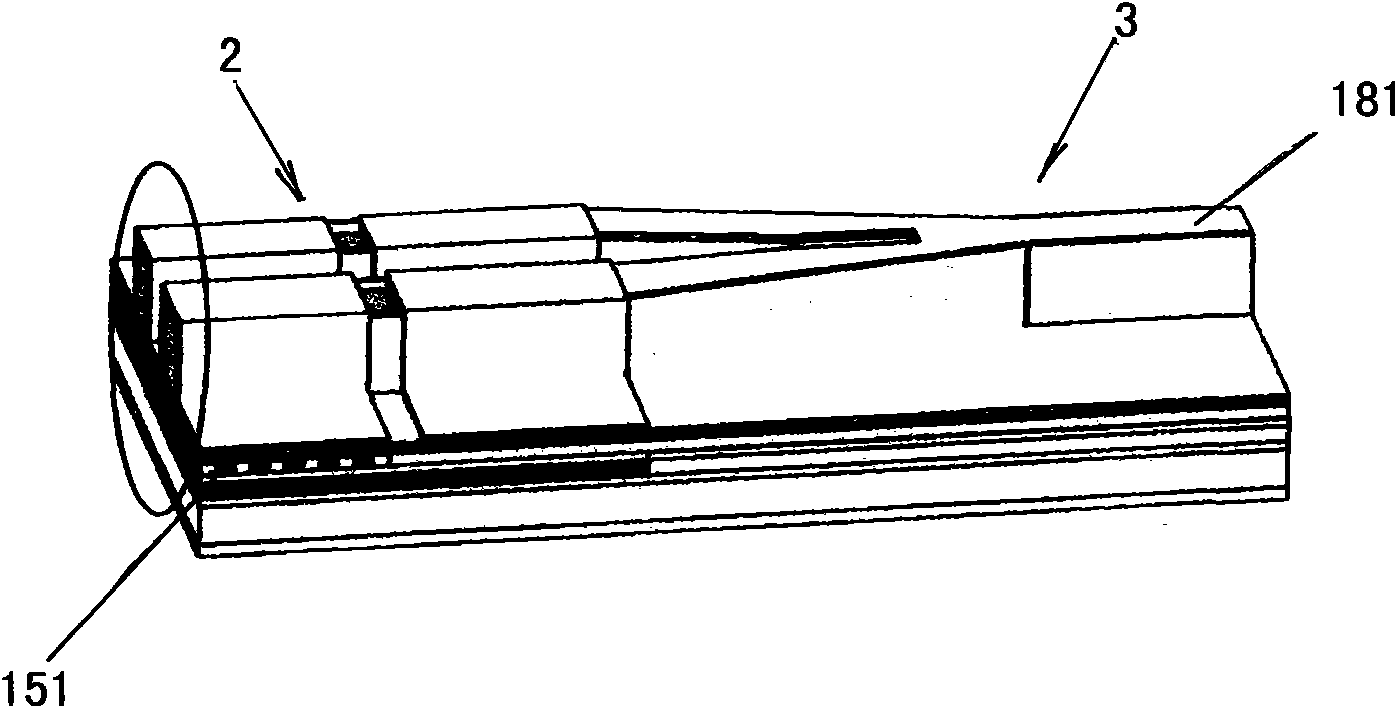

[0037] please refer again figure 1 , figure 2 , image 3 with Figure 4 A kind of manufacturing method based on Y waveguide double distributed feedback laser+double amplifier provided by the present invention, comprises following manufacturing steps:

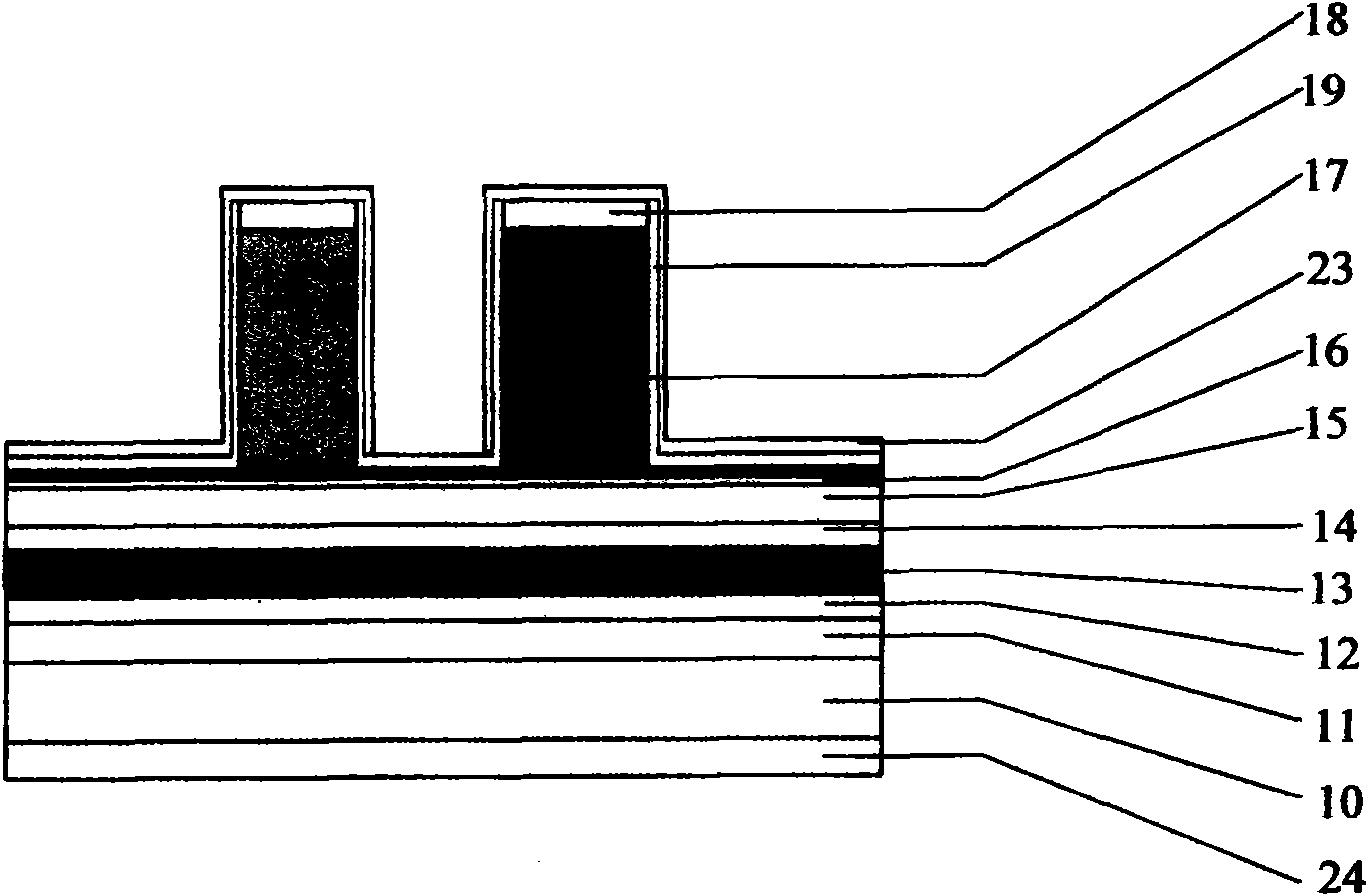

[0038] Step 1: Select an N-type indium phosphide substrate 10;

[0039] Step 2: On the N-type indium phosphide substrate 10, sequentially epitaxially fabricate an InP buffer layer 11 of 1.5 μm, a lower waveguide layer 12 of 100 nm, a multi-quantum well active region 13, an upper waveguide layer 14 of 100 nm and a grating layer 15, Forming a material structure; wherein the multi-quantum well active region 13 is an InGaAsP material, the bandgap wavelength of the material is 1.55 μm, the number of quantum wells is 6, and the total thickness is 90 nanometers;

[0040] Step 3: Fabricate the passive waveguide region 3 on one side of the material structure, and the active waveguide region 2 on the other side; when making the passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com