Mechanical draft systems

a mechanical draft and control device technology, applied in combustion control, failure to operate, combustion failure safe, etc., can solve problems such as unnecessarily duplicated components and functions, unnecessary coordination among the various controllers, and complicated coordination between the various controllers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

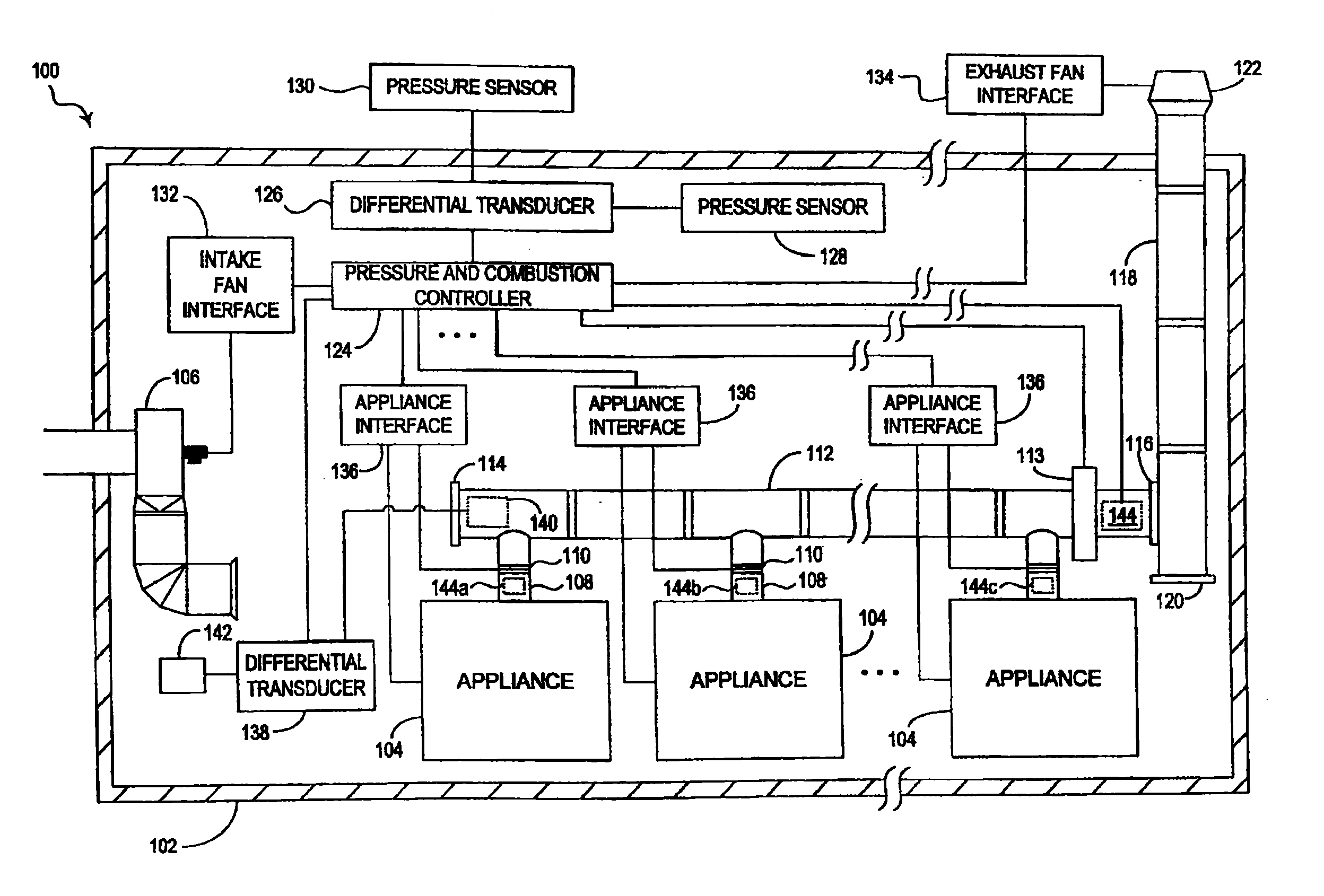

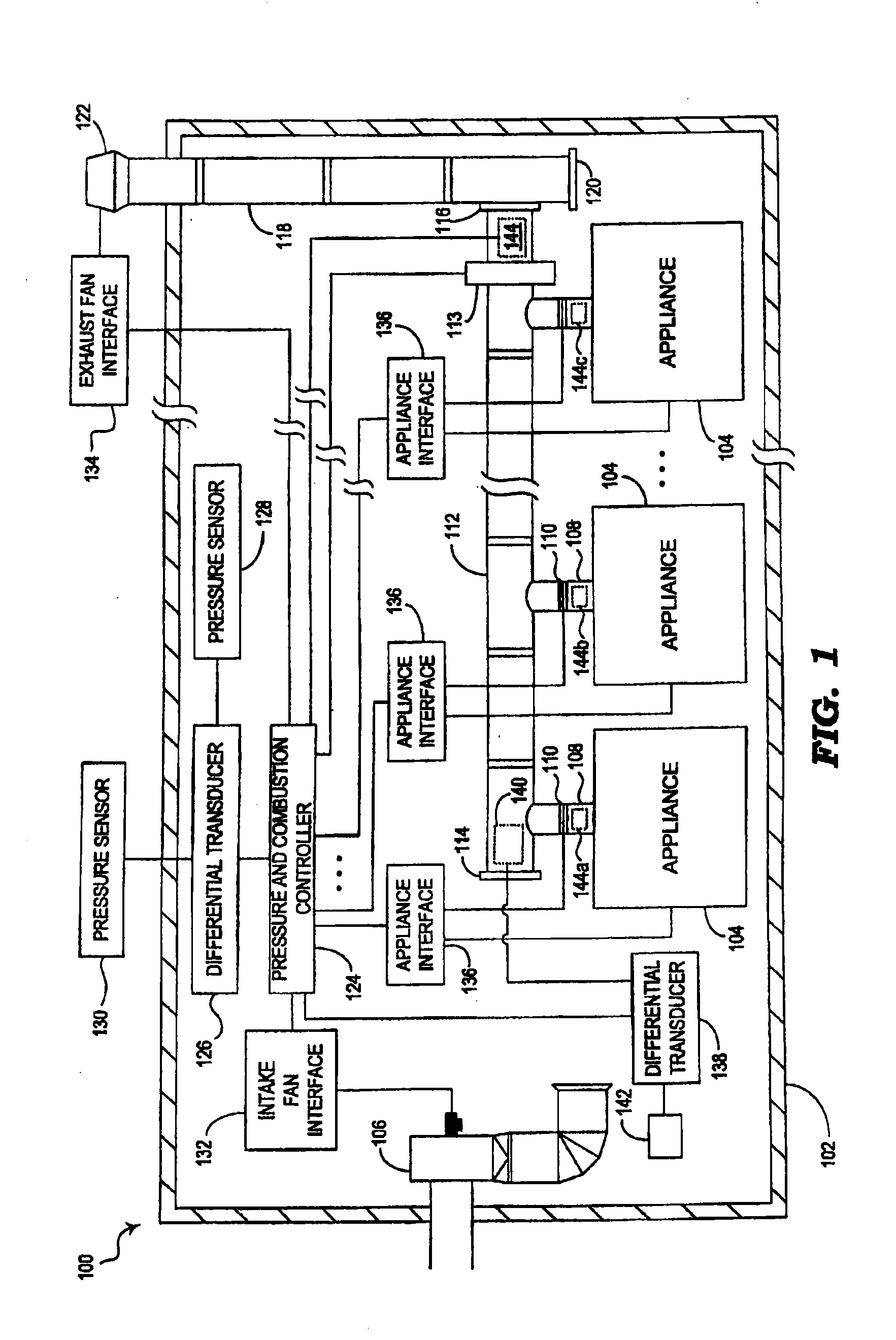

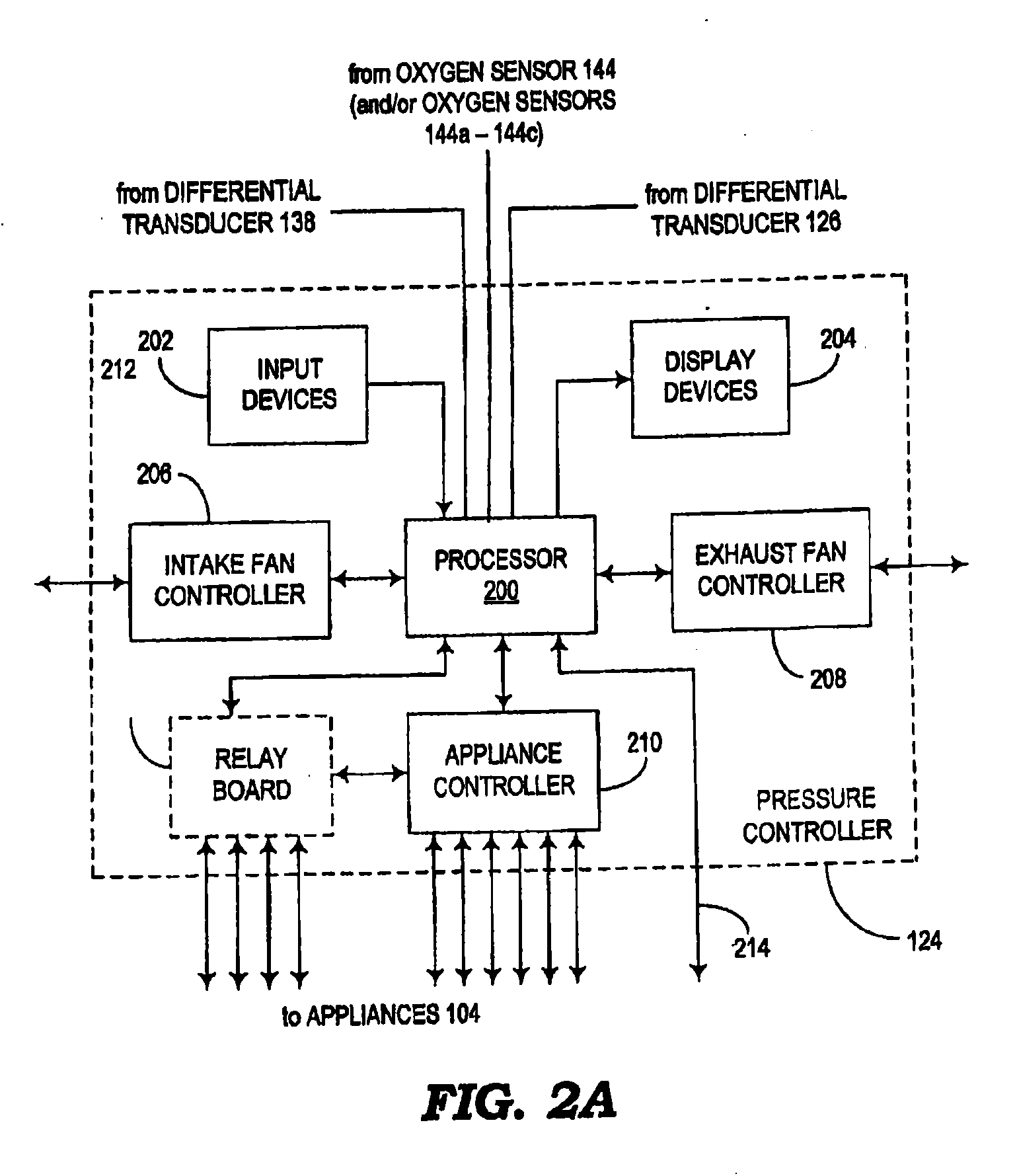

[0033]Fan assemblies, mechanical draft systems and methods are provided. In some embodiments, combustion air is drawn into a mechanical room and supplied to combustion or heating devices and air exhausted from the combustion or heating devices is vented from the mechanical room into the atmosphere. Some embodiments of the controllers are capable of controlling the on / off state and speed of intake fans and exhaust fans and can also control any number of appliances, such as furnaces or boilers, within the system. The unitary controllers disclosed herein may be configured using microprocessor elements or other suitable electrical components for providing greater functionality than conventional exhaust system controllers. Also, the controllers can be programmed in the field and reprogrammed as desired allowing greater flexibility.

[0034]The controllers can be initialized during the installation or set-up of the mechanical draft system. The initialization process involves entering informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com