Method to improve engine operating efficiency and reduce harmful gas emissions

A harmful gas and work efficiency technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of increasing the operating load and production costs of automobiles, occupying limited space in automobiles, and large heat exchanger volume, etc., to achieve improvement The effect of work efficiency, less space occupation and low outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

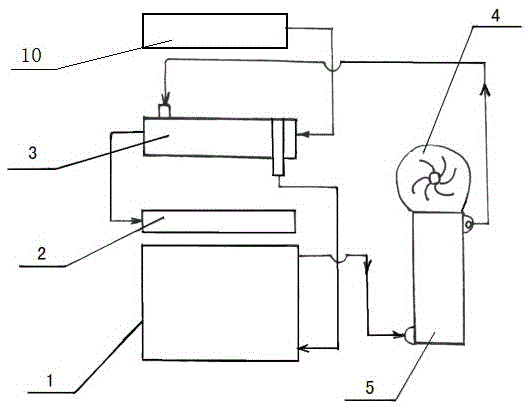

Embodiment 1

[0039] refer to figure 1 , the device of the present embodiment that can improve the working efficiency of the engine and reduce harmful gas emissions includes a turbocharger 10, an engine 1, an intake manifold 2, an intercooler 3, a cooling fan 4, and a cooling water tank I5. Cooler 3 is a counter-current heat exchange cooler, which is composed of alternately arranged fin structures and thin channel structures (for specific structures, please refer to Chinese patents 201210029210.4 and 201220042482.3; the heat transfer coefficient of the radiator is very High, relevant data show that the heat transfer coefficient of the air side can reach more than 300W / ㎡·℃, while the heat transfer coefficient of the current intercooler is generally less than 50W / ㎡·℃), the outlet of the fin side passes through the pipeline It is connected to the intake manifold 2, the inlet is connected to the turbocharger 10 through pipelines, and the engine 1 is connected to the coolant inlet of the heat di...

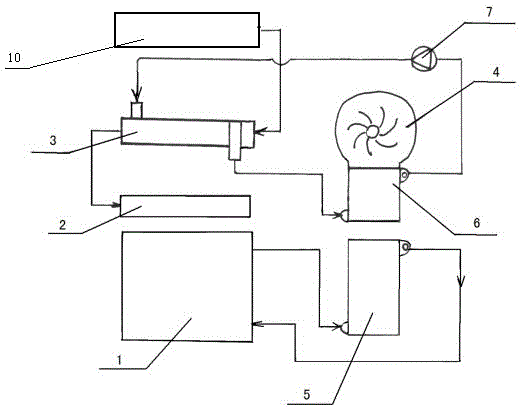

Embodiment 2

[0044] refer to figure 2 , the device of this embodiment that can improve the working efficiency of the engine and reduce harmful gas emissions, including a turbocharger 10, an engine 1, an intake manifold 2, an intercooler 3, a cooling fan 4, a cooling water tank I5, and a cooling water tank II6 1. Coolant circulation pump 7, the intercooler 3 is a counter-current heat exchange cooler, and the counter-current heat exchange cooler is composed of alternately arranged fin structures and thin channel structures (for specific structures, please refer to Chinese patent 201210029210.4 and 201220042482.3), the outlet on the fin side is connected to the intake manifold 2 through the pipeline, the inlet is connected to the vortex supercharger 10 through the pipeline, and the coolant outlet of the cooling water tank II6 is connected through the pipeline and the coolant circulation pump 7 It is connected with the coolant inlet of the intercooler 3, and the coolant outlet of the intercoo...

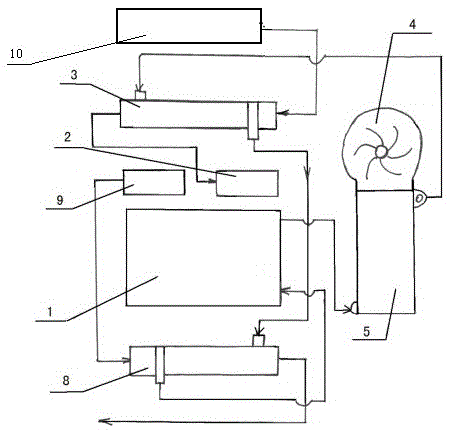

Embodiment 3

[0049] refer to image 3 , the device of this embodiment that can improve the working efficiency of the engine and reduce harmful gas emissions, including a turbocharger 10, an engine 1, an intake manifold 2, an intercooler 3, a cooling fan 4, a cooling water tank I5, a sound-absorbing heat exchange 8, the intercooler 3 is a counter-flow heat exchange cooler, and the counter-flow heat exchange cooler is composed of alternately arranged fin structures and thin channel structures (for specific structures, please refer to Chinese patents 201210029210.4 and 201220042482.3), The outlet on the fin side is connected to the intake manifold 2 through a pipeline, and the inlet is connected to the turbocharger 10 through a pipeline. The structure of the muffler heat exchanger 8 is the same as that of the intercooler 3; the intercooler 3 The coolant outlet of the engine 1 is connected to the coolant inlet of the silencing heat exchanger 8 through a pipeline, and the coolant outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com