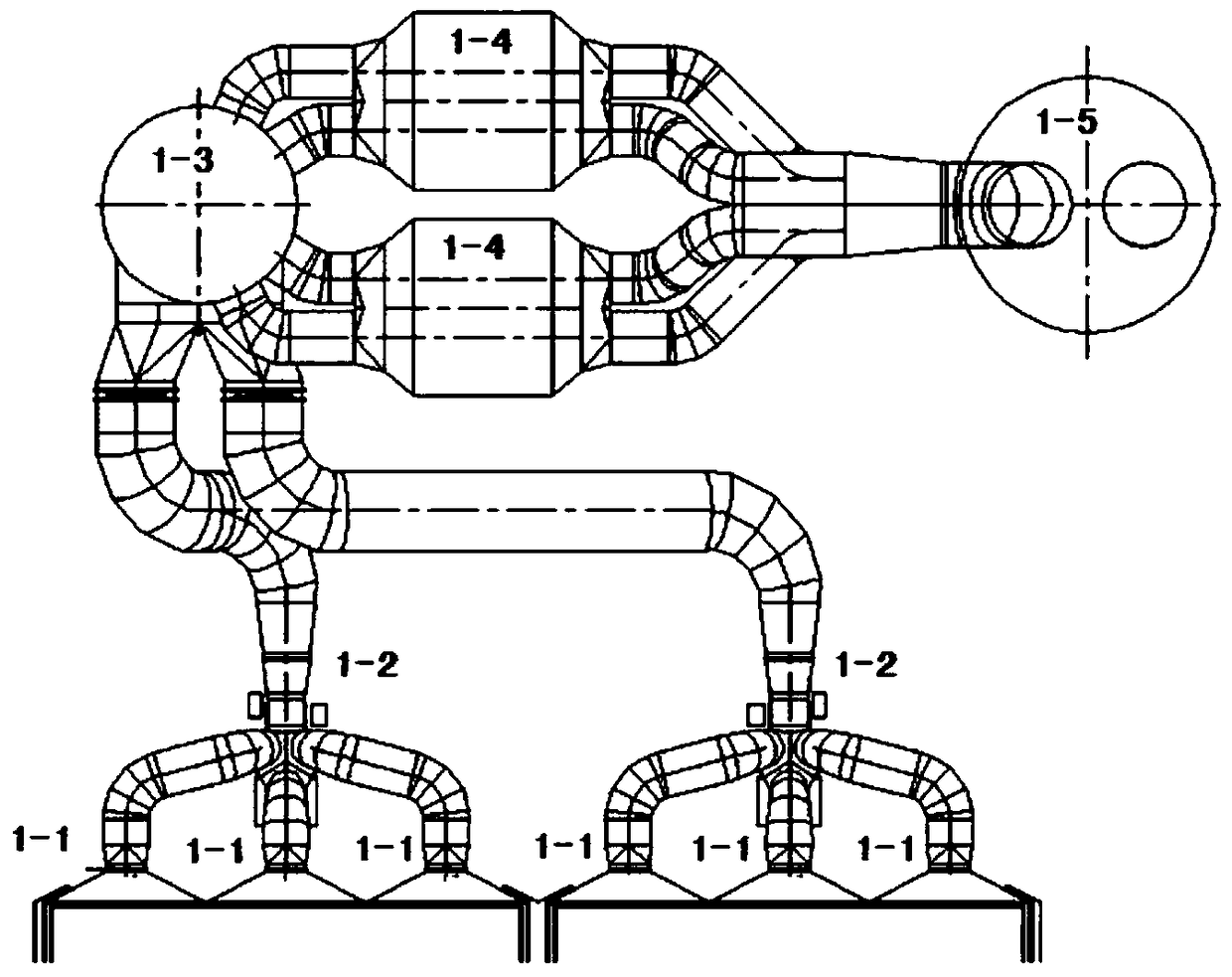

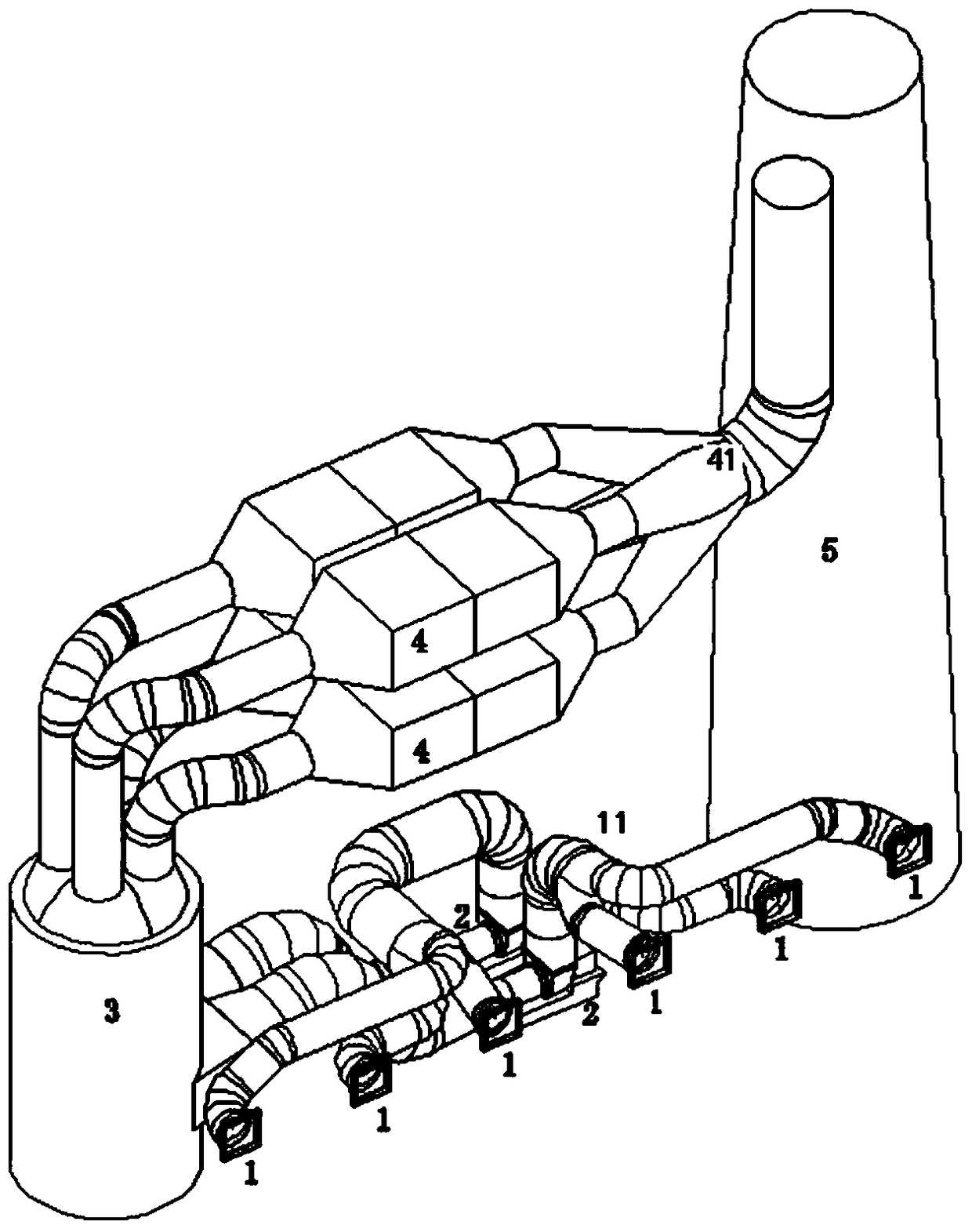

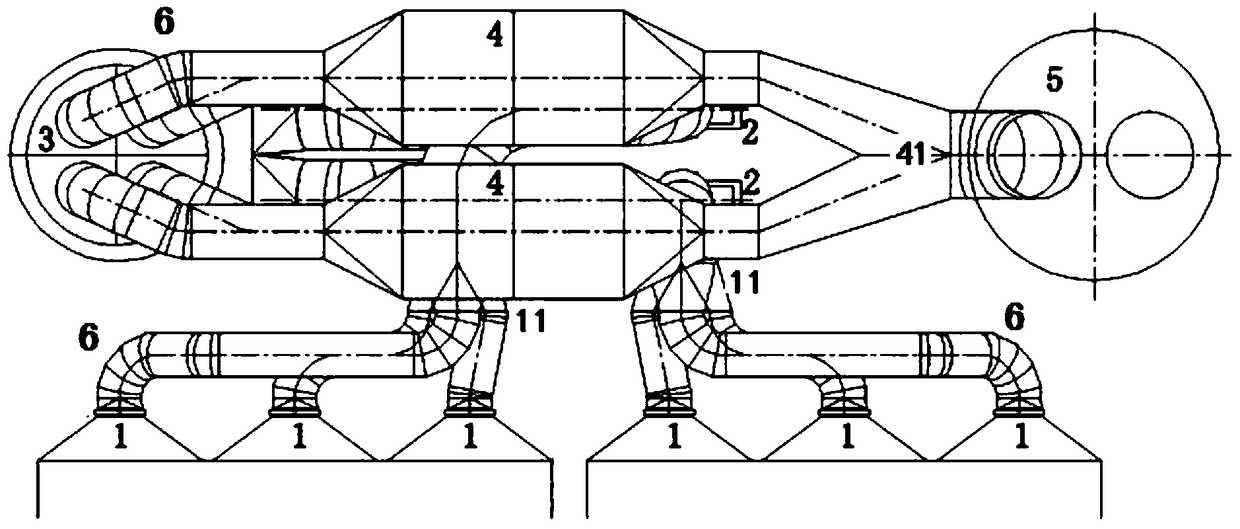

Combined layout structure of the rear flue air system with six outlets of dust collectors in power plants

A technology of layout structure and wet electrostatic precipitator, which is applied in the direction of air induction, combustion method, lighting and heating equipment, etc., can solve the problems of large area occupation, large flue resistance, long flue, etc., to reduce pressure loss, smoke The effect of less road materials and reducing power consumption of the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] refer to Figure 2 to Figure 4 The joint layout structure of the rear flue air system of the six outlets of the dust collector in the power plant is shown, including six outlets of the dust collector 1, the structure of the induced draft fan 2, the desulfurization absorption tower 3, the structure of the wet electrostatic precipitator 4 and the chimney 5, and the structure of the induced draft fan 2 consists of Two induced draft fans form a double-row induced draft fan structure, and every three dust collector outlets 1 are connected to the air inlet of an induced draft fan, and the air outlets of the two induced draft fans are each connected to an air inlet of the desulfurization absorption tower 3; wet electrostatic precipitator The device structure 4 is composed of four wet electrostatic precipitators; the desulfurization absorption tower 3 is provided with two air inlets and four air outlets, and each of the four air outlets of the desulfurization absorption tower 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com