Air-conditioning and cooling tower group that can reduce the back-mixing rate of hot and humid air

An air-conditioning cooling tower group, hot and humid air technology, applied in the direction of water shower coolers, heat exchanger types, lighting and heating equipment, etc., can solve the cooling tower exhaust short circuit, poor exhaust air, affecting the effect of cooling and heating and other problems, to achieve the effect of improving operating efficiency, reducing discharge resistance, and reducing ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments of the specification.

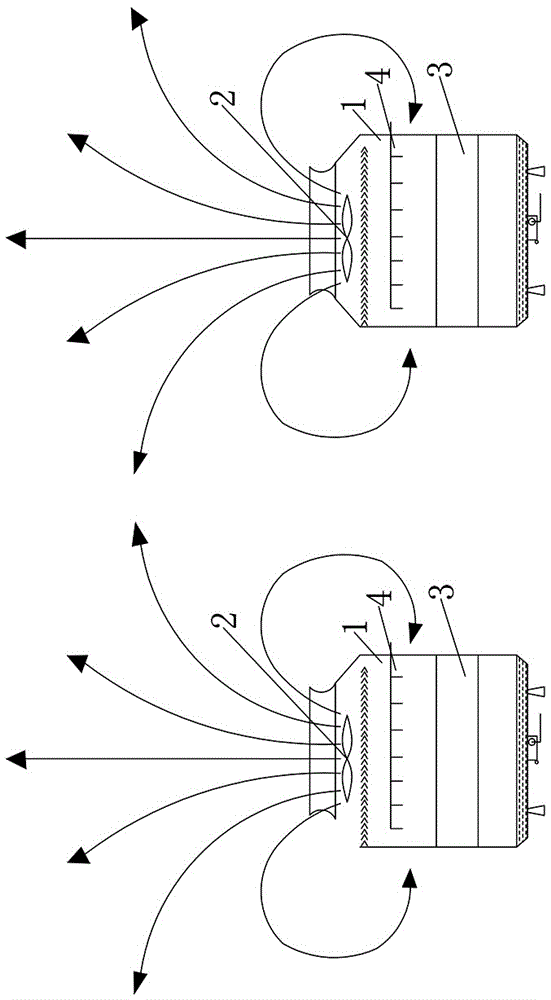

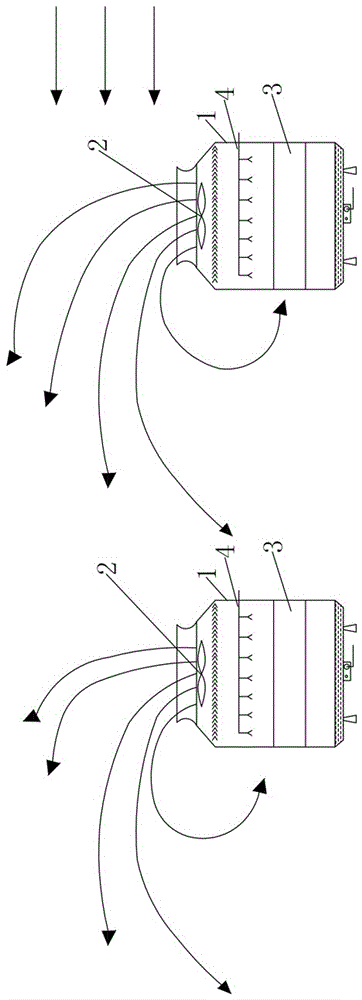

[0026] Figure 4 Shows the first embodiment of the air conditioning cooling tower group of the present invention that can reduce the backmixing rate of hot and humid air. Tower 1 follows the direction of ambient wind flow (such as Figure 4 Indicated by the horizontal arrow in the middle) is arranged in more than two rows, and the height of the air cylinder 10 is gradually reduced along the direction in which the ambient wind flows. In this embodiment, two rows of cooling towers 1 are provided. In the air conditioning cooling tower group capable of reducing the backmixing rate of hot and humid air of the present invention, a wind tube 10 is installed at the top of the cooling tower 1, which can create good aerodynamic conditions, reduce ventilation resistance, and send the hot and humid air discharged from the cooling tower 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com