Scaling prevention and removal device for mine gas drainage equipment

A gas drainage and equipment technology, applied in mining equipment, gas discharge, safety devices, etc., can solve the problems of reducing the efficiency of drainage equipment, reducing the internal space of equipment, and the drainage system cannot operate, so as to reduce internal friction and reduce Discharge resistance, scale prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

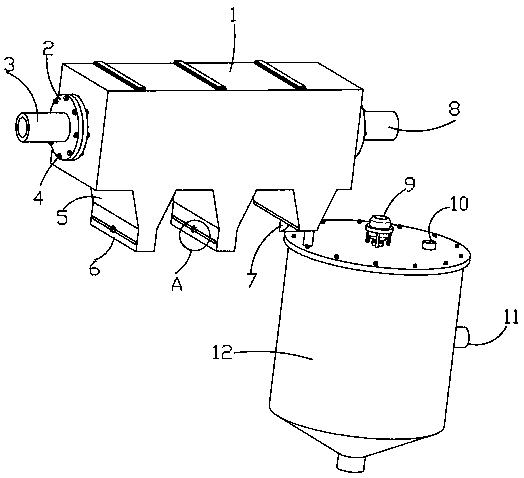

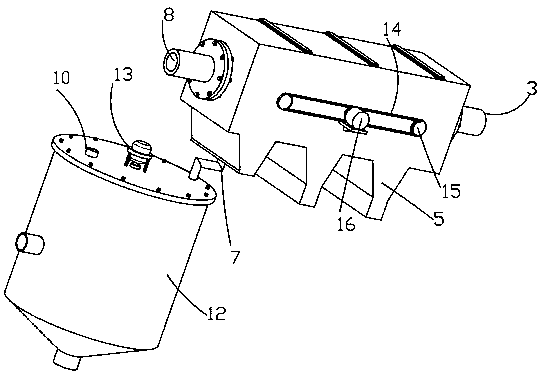

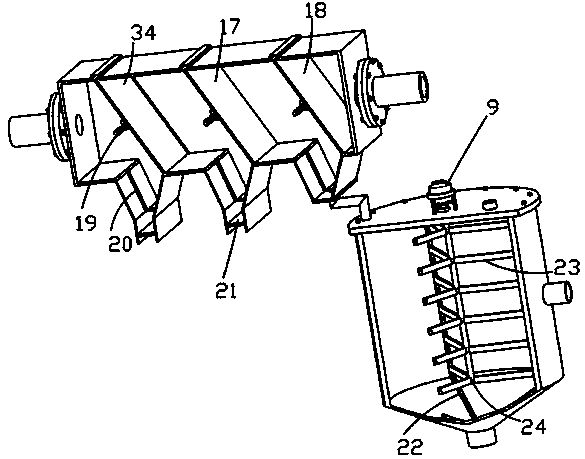

[0032] Such as Figure 1-6The scale prevention and removal device for mining gas extraction equipment shown includes a treatment box 1, an air inlet pipe 3, an air outlet pipe 8 and a sedimentation box 12. The treatment box 1, the air inlet pipe 3 and the air outlet pipe 8 are all fixedly connected with Flange 2, flange 2 is uniformly provided with first bolts 4 along the circumferential direction, adjacent flanges 2 are fixedly connected by first bolts 4, and gaskets are arranged between flanges 2, and the top of processing box 1 is fixedly connected with three Set the same mounting holes 25, the processing case 1 is provided with a block cap 33 at the top of the mounting hole 25, the processing case 1 and the block cap 33 are screwed with the second bolt 31 through the threaded holes evenly offered, and between the processing case 1 and the block cap 33 A sealing gasket is provided, and the treatment box 1 is fixedly connected with a slant plate 30 below the installation hol...

Embodiment 2

[0034] Such as Figure 1-6 The scale prevention and removal device for mining gas extraction equipment shown includes a treatment box 1, an air inlet pipe 3, an air outlet pipe 8 and a sedimentation box 12. The treatment box 1, the air inlet pipe 3 and the air outlet pipe 8 are all fixedly connected with Flange 2, flange 2 is uniformly provided with first bolts 4 along the circumferential direction, adjacent flanges 2 are fixedly connected by first bolts 4, and gaskets are arranged between flanges 2, and the top of processing box 1 is fixedly connected with three Set the same mounting holes 25, the processing case 1 is provided with a block cap 33 at the top of the mounting hole 25, the processing case 1 and the block cap 33 are screwed with the second bolt 31 through the threaded holes evenly offered, and between the processing case 1 and the block cap 33 A sealing gasket is provided, and the processing box 1 is fixedly connected with a slant plate 30 below the installation h...

Embodiment 3

[0036] Such as Figure 1-6 The scale prevention and removal device for mining gas extraction equipment shown includes a treatment box 1, an air inlet pipe 3, an air outlet pipe 8 and a sedimentation box 12. The treatment box 1, the air inlet pipe 3 and the air outlet pipe 8 are all fixedly connected with Flange 2, flange 2 is evenly provided with first bolt 4 along the circumferential direction, three groups of identical mounting holes 25 are fixedly connected to the top of processing box 1, and processing box 1 is provided with a cap 33 at the top of mounting holes 25, and processing box 1 And block cap 33 is threadedly connected with second bolt 31 by the threaded hole that evenly offers, and be provided with gasket between processing case 1 and block cap 33, processing case 1 is fixedly connected with swash plate 30 at mounting hole 25 below, and swash plate 30 The inclined first filter plate 34, the second filter plate 17 and the waterproof breathable membrane 18 are plugg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com