Double-shaft powder stirring humidifying device

A humidification device and powder technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as low production efficiency, uneven humidification of powder mixing, and large driving resistance. Achieve the effects of easy maintenance, prevent powder accumulation and agglomeration, and reduce discharge resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

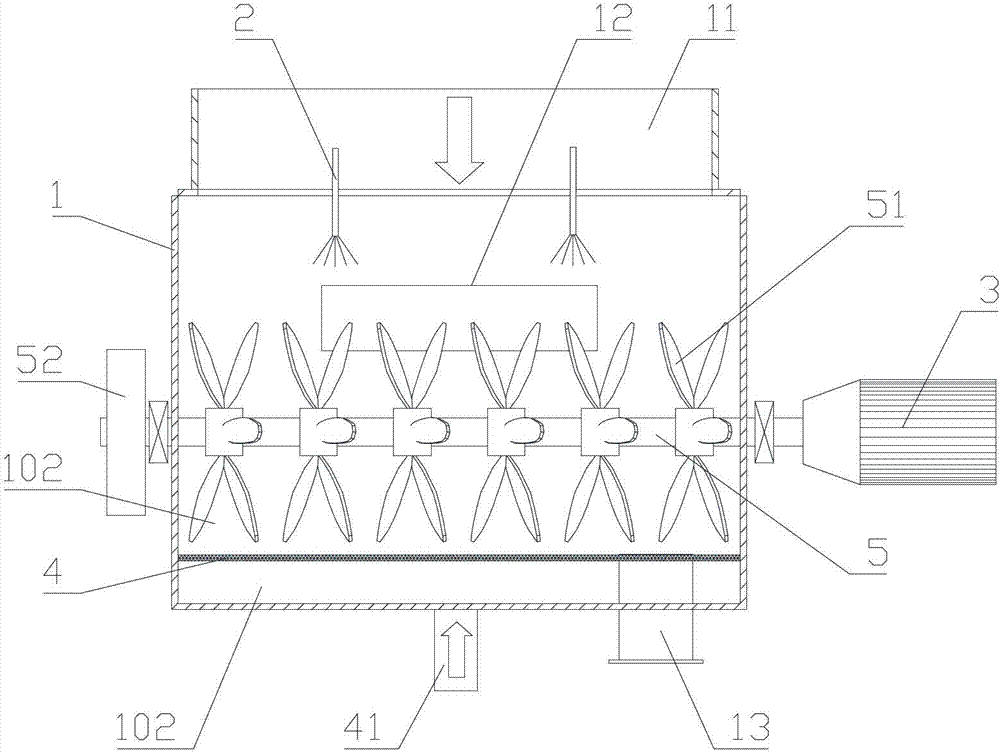

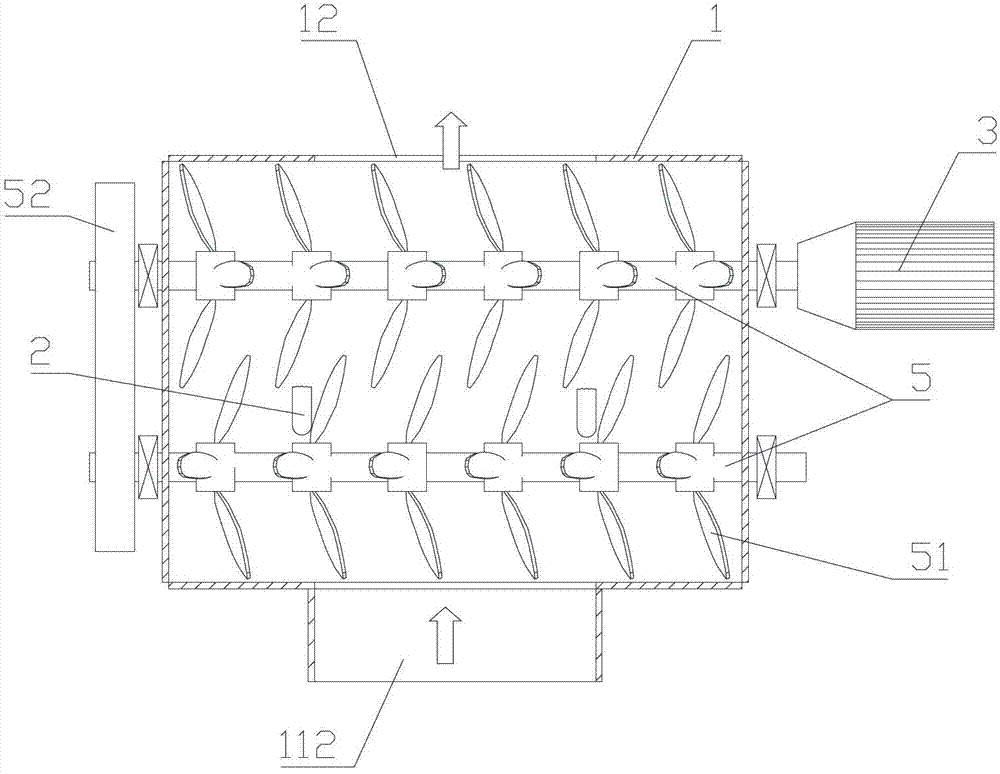

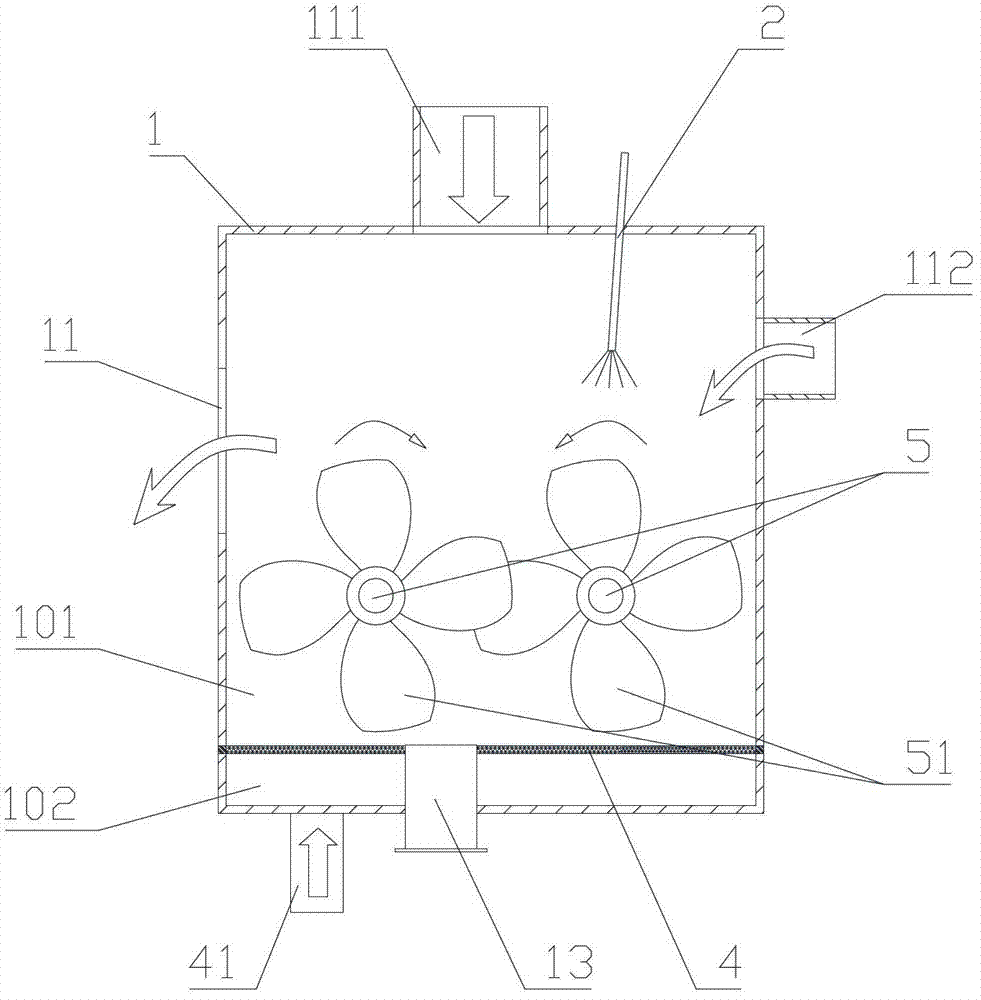

[0019] Such as Figures 1 to 3 Shown is an embodiment of the present invention, a double-shaft powder stirring and humidifying device, including a stirring bin 1, a stirring mechanism is arranged in the stirring bin, and a top wall or a side wall of the stirring bin is provided with A water spray device 2, the mixing chamber is provided with a feed inlet 11 and a discharge outlet 12, the stirring mechanism is driven by the driving device 3, the bottom of the stirring chamber is provided with a fluidization device, and the stirring mechanism is located at above the fluidization unit. The fluidization device includes a fluidization cloth 4, and the fluidization cloth is fixed on the side wall of the stirring bin to divide the inner space of the stirring bin into a stirring and humidifying area 101 above the fluidizing cloth and a flow area 101 below the fluidizing cloth. In the fluidization area 102, the bottom wall or the bottom of the side wall of the mixing chamber is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com