Coal-burning boiler limestone dual-purpose desulfurizing method

A coal-fired boiler and limestone technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as unaffordable electricity bills, immature processes, and large power consumption, and reduce operating costs and operating costs. The effect of maintenance fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

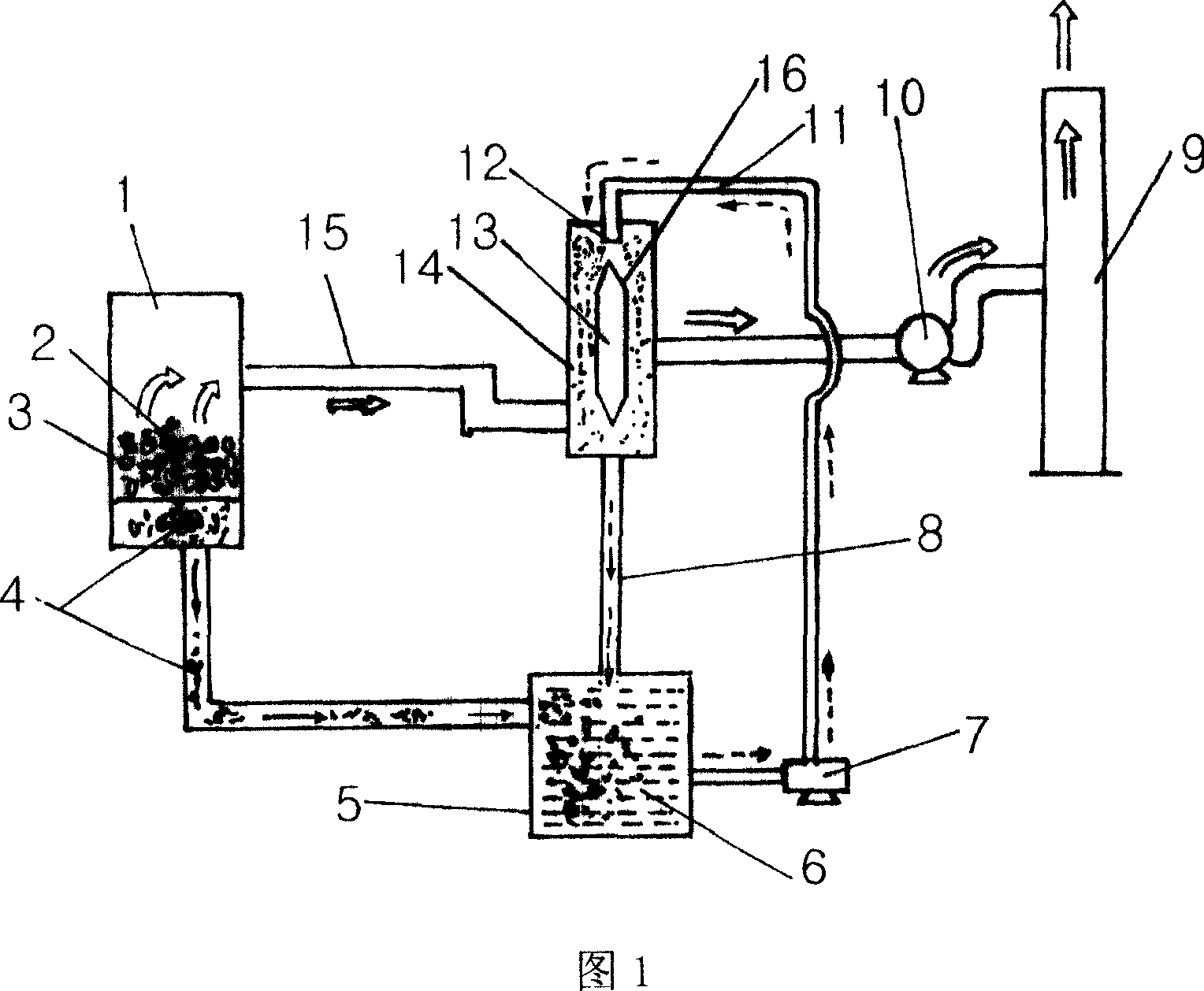

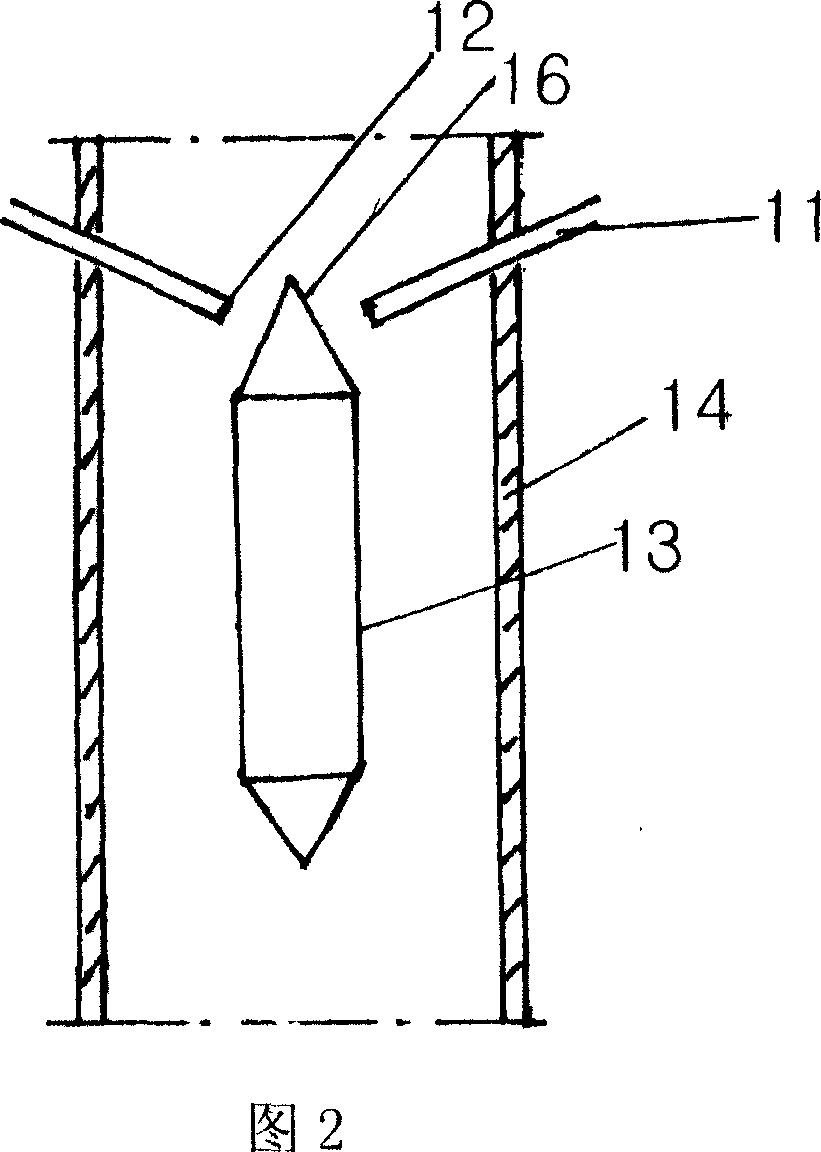

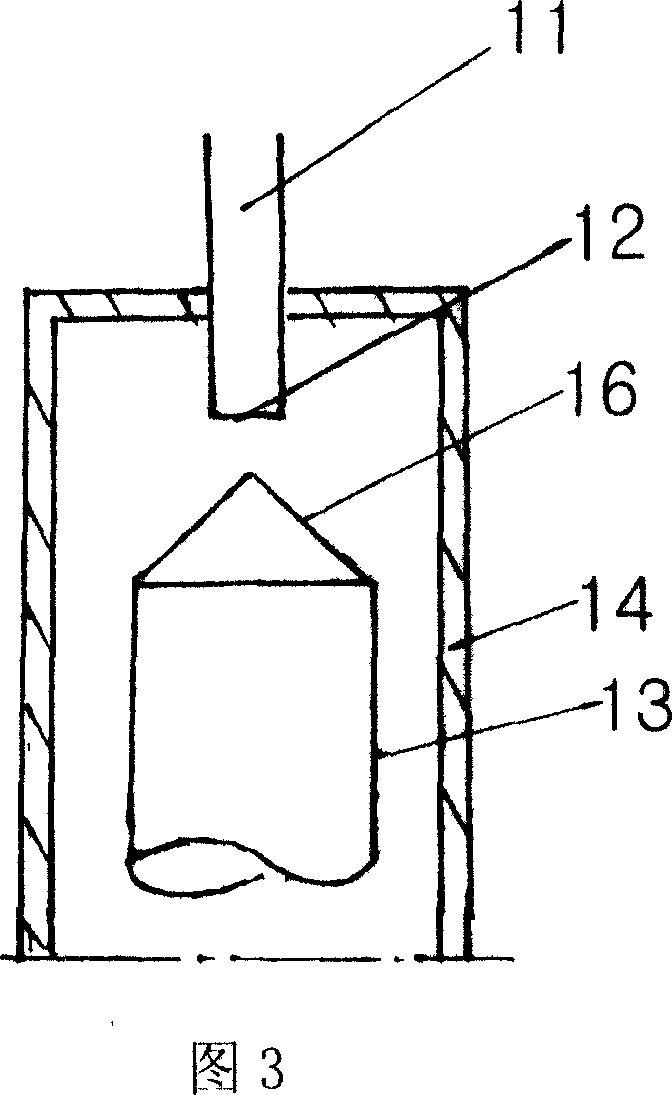

[0026] The invention provides a limestone double-effect desulfurization method for a coal-fired boiler. In the structural diagram of the limestone double-effect desulfurization device for a coal-fired boiler shown in Figure 1, the device organically combines the dry desulfurization and wet desulfurization methods into a double-effect desulfurization method, which reduces the cost of desulfurization, and the emission of sulfur dioxide is much lower than that of the two methods. Emissions from each method alone.

[0027] The specific process of described double-effect desulfurization described in conjunction with accompanying drawing is as follows:

[0028] 1) The calcium content is 30 ~ 60Wt%, the particle size is 0.25 ~ 50Cm 3 The limestone 3 and the sulfur content of the coal 2 are put into the coal-fired boiler 1 for co-combustion according to the weight ratio of 1:1, 1:2, 1:3, 1:4, 1:5, so that the coal combustion produces Part of SO 2 Formation of CaSO on limestone surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com