Power plant carbon and oxygen circulation utilization device and process of device

A carbon-oxygen and power plant technology, applied in the chemical industry, petroleum industry, carbon monoxide, etc., can solve the problems of waste of CO2 and O2 resources, low thermal energy conversion rate, environmental pollution, etc., to improve the net conversion rate of thermal energy, reduce equipment investment, The effect of saving coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

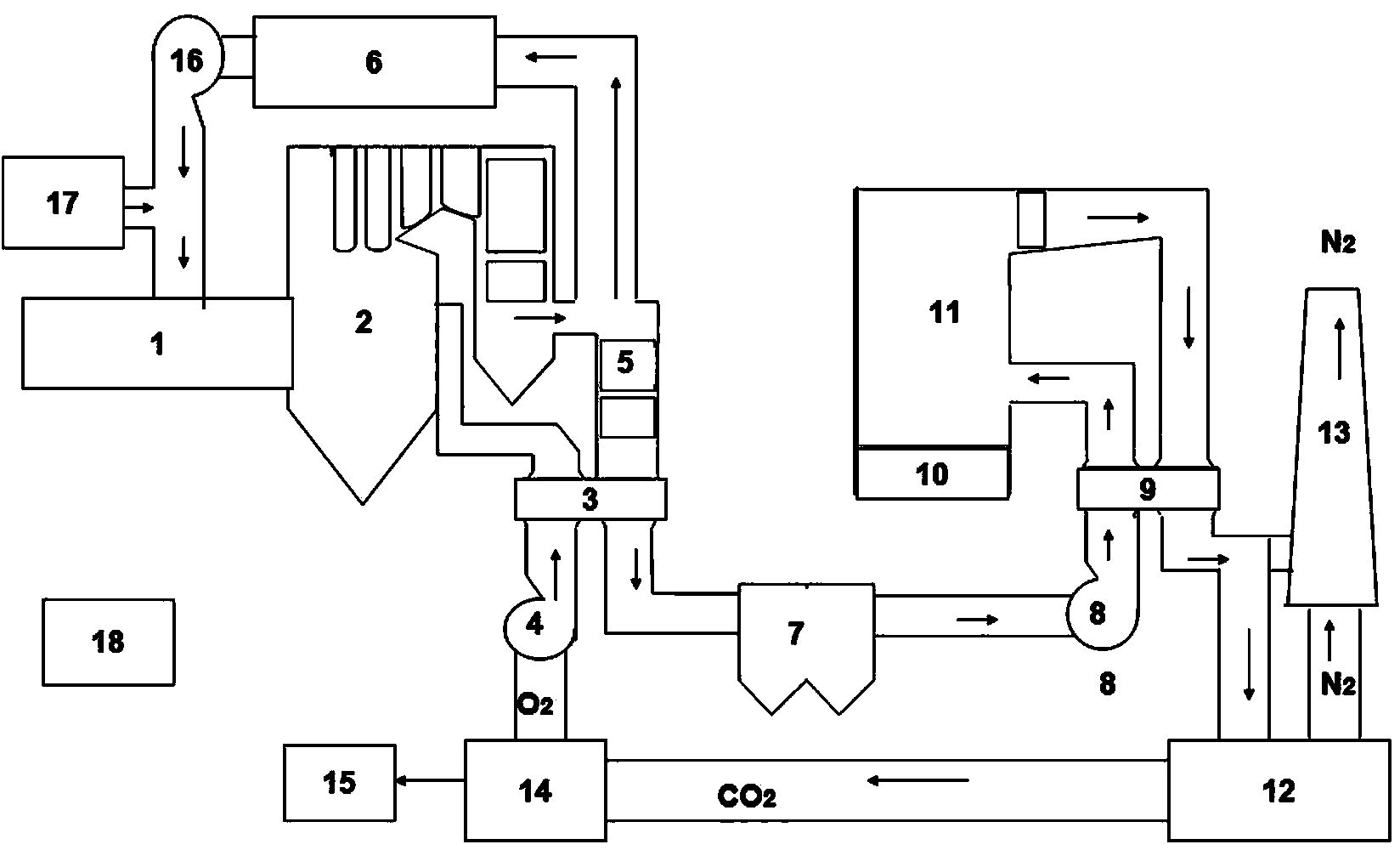

[0029] Embodiment 1: as figure 1 As shown, the carbon-oxygen recycling device of the power plant consists of a coal feeder 17, a CO2 return device 6, a plasma torch catalyst 1, an energy-saving boiler 2, a denitrification device 5, a heat exchanger 3, a dust collector 7, a booster fan 16, and an induced draft fan 8. Composed of desulfurization slag liquid 10, desulfurization tower 11, heat exchanger 9, CO2 capture separator 12, deoxidizer 14, blower 4, carbon recovery device 15, remote explosion-proof master control detection system 18, and chimney 13; the plasma One end of the torch catalytic converter 1 is connected to the coal feeder 17 and the CO2 reflux device 6, and the other end is connected to the flue gas inlet at the lower part of the energy-saving boiler 2. The lower part is also provided with a flue gas outlet, and the lower flue gas outlet is connected to the flue gas inlet flue of the heat exchanger 3; the flue gas outlet flue of the heat exchanger 3 is connected...

Embodiment 2

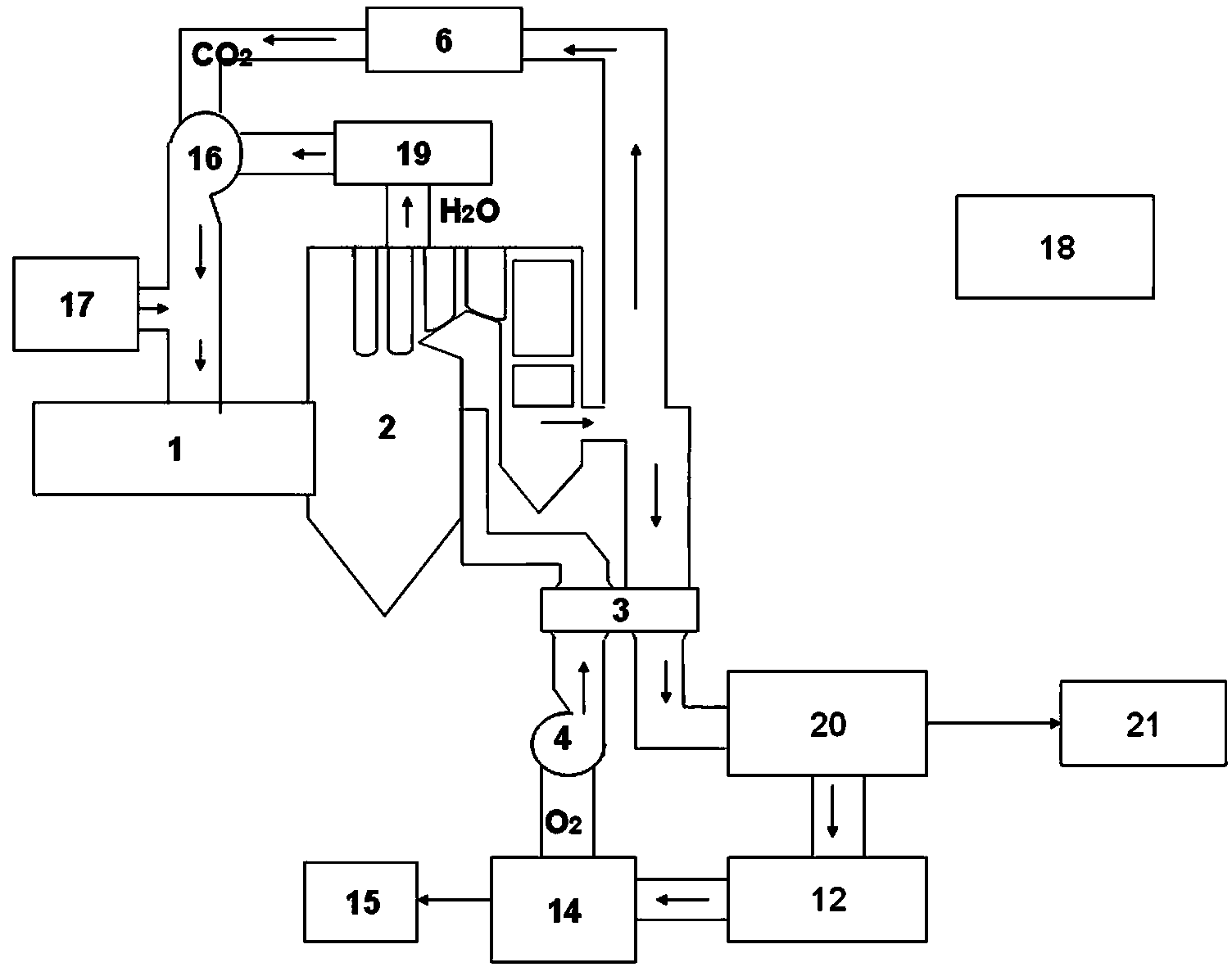

[0067] Embodiment 2: as figure 2 As shown, the carbon-oxygen recycling device of the power plant consists of a coal feeder 17, a CO2 return device 6, a plasma torch catalyst 1, an energy-saving boiler 2, a heat exchanger 3, a booster fan 16, a CO2 capture separator 12, and a deoxidizer 14 , blower 4, carbon recoverer 15, remote explosion-proof master control detection system 18, water vapor tank 19, purifier 20, sulfur-based compound fertilizer production line 21; one end of the plasma torch catalyst 1 is connected to the coal feeder 17, and the other end It is connected with the flue gas inlet at the lower part of the energy-saving boiler 2, the top of the energy-saving boiler 2 is provided with an outlet, and the outlet at the top is connected with the CO2 reflux device 6, the lower part of the energy-saving boiler 2 is provided with a flue gas outlet, and the lower flue gas outlet is connected with the heat exchanger 3 The flue gas inlet flue is connected; the water vapor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com