Method for coking tar residue in coal blending manner

A coal blending coking and tar slag technology, applied in coking ovens, petroleum industry, etc., can solve problems affecting processing progress and product quality, and achieve the effects of saving coal sources, solving environmental pollution, and increasing the lump coke rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

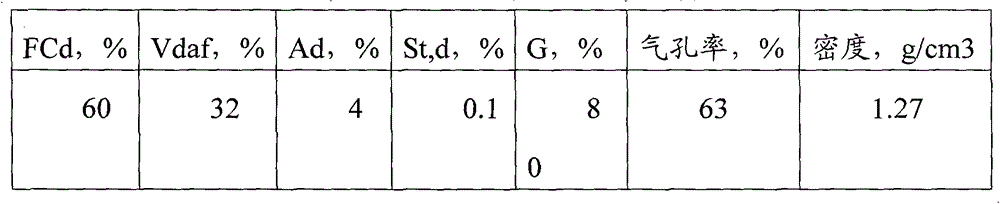

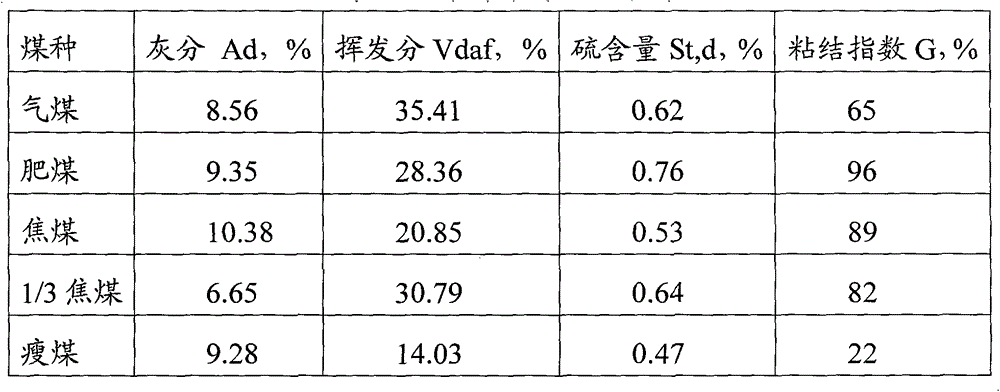

[0014] 20kg small coke oven with tar residue coking experimental device or equipment and industrial analysis of raw materials. Device or equipment: 20kg experimental coke oven and its matching raw coal crushing device, coal quality and strength analysis and testing device; Raymond pulverizer for crushing tar residue. The collection and preparation of raw coal and coke samples are carried out in strict accordance with GB1997-89. The tar residue used in the experiment was taken from a tar residue waste site of a coking company, and its physical and chemical properties are shown in Table 1. Coking raw coal is taken from the company's raw coal yard, and its industrial analysis is shown in Table 2.

[0015] Table 1 Physicochemical properties of tar residue

[0016]

[0017] Table 2 Industrial Analysis of Raw Coal

[0018]

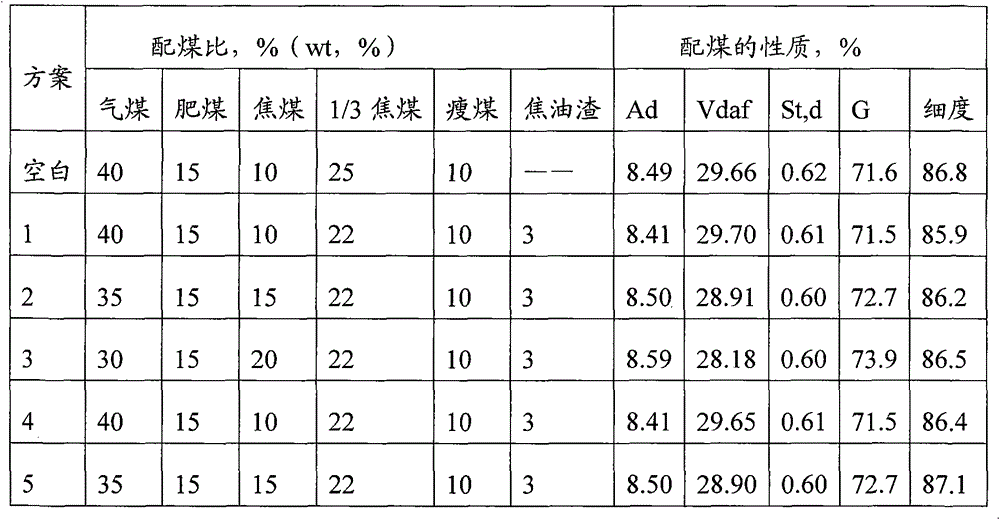

[0019] From the physical and chemical properties of tar residue and the properties of coking coal, it can be seen that the role of tar residue in coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com