Method for enhancing vacuum of steam condenser

A condenser and vacuum technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve unsatisfactory problems and achieve the effects of saving power generation costs, significant economic benefits, and reduced coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

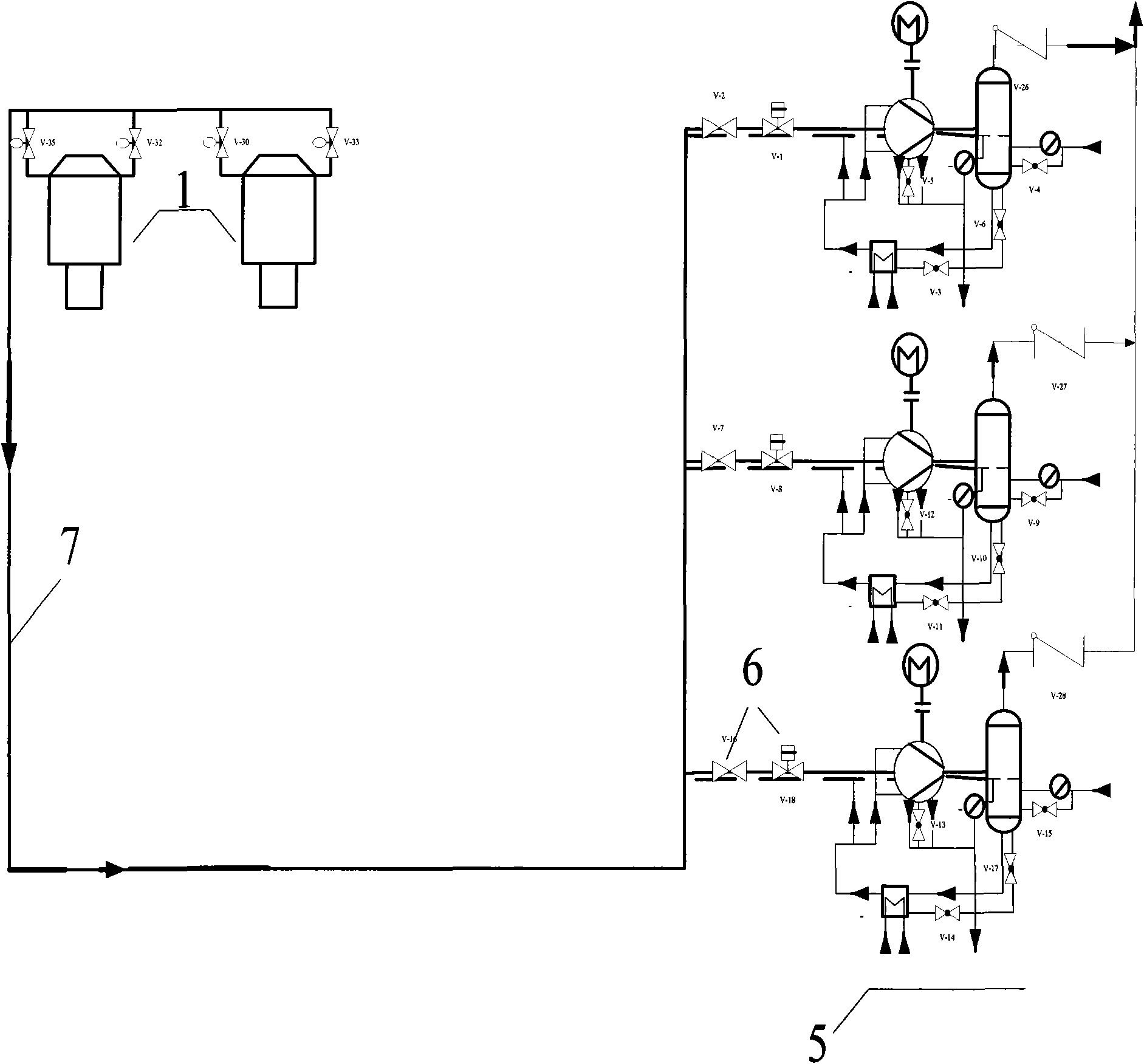

[0024] figure 1 It is a typical vacuum pumping system for condenser of condensing steam turbine generator set. This picture shows the vacuum pumping system of 300MW and 600MW units. The vacuum pumping system of 200MW unit only has two jet vacuum pumps (omitted).

[0025] The method that cooler of the present invention installs and implements:

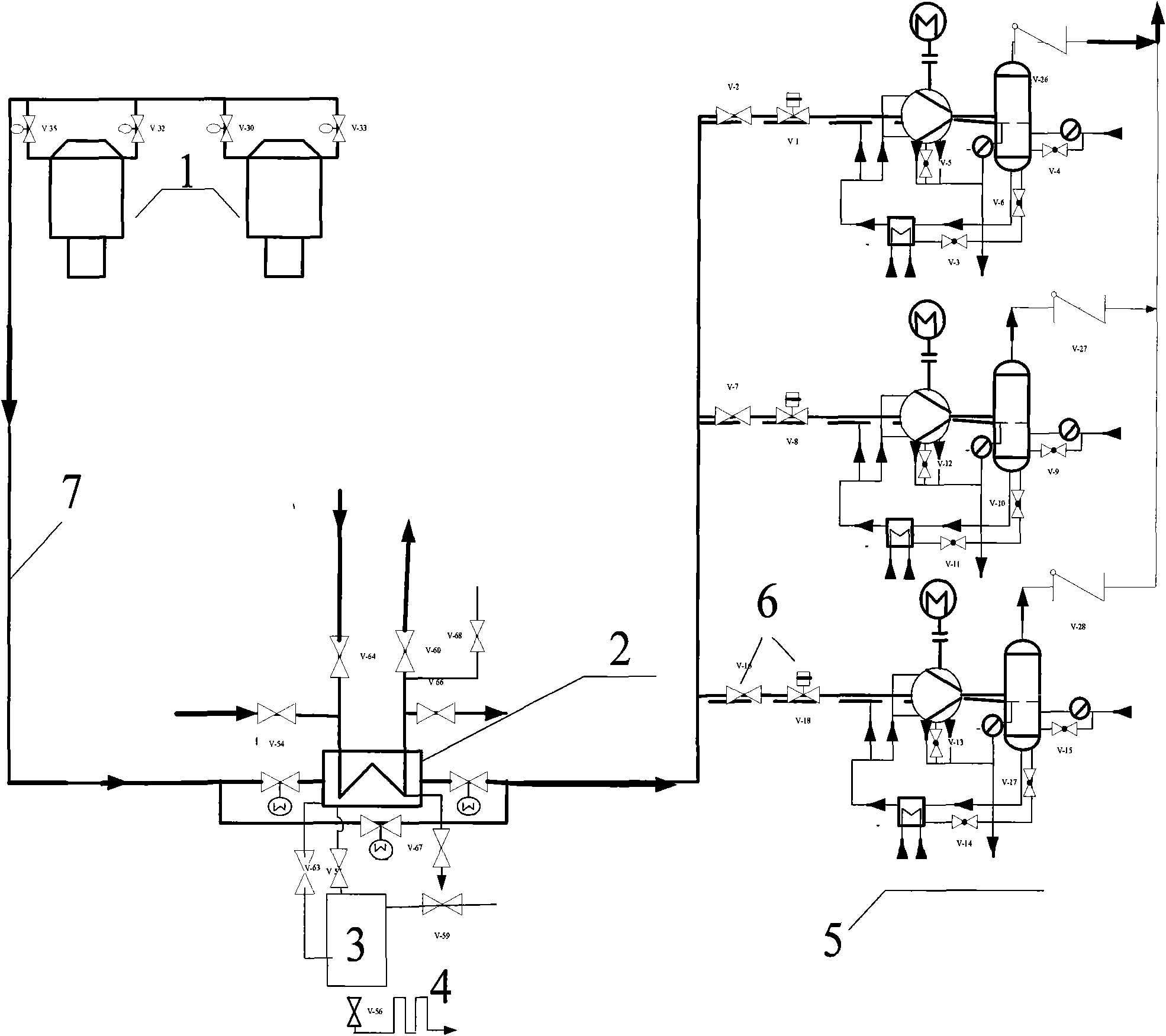

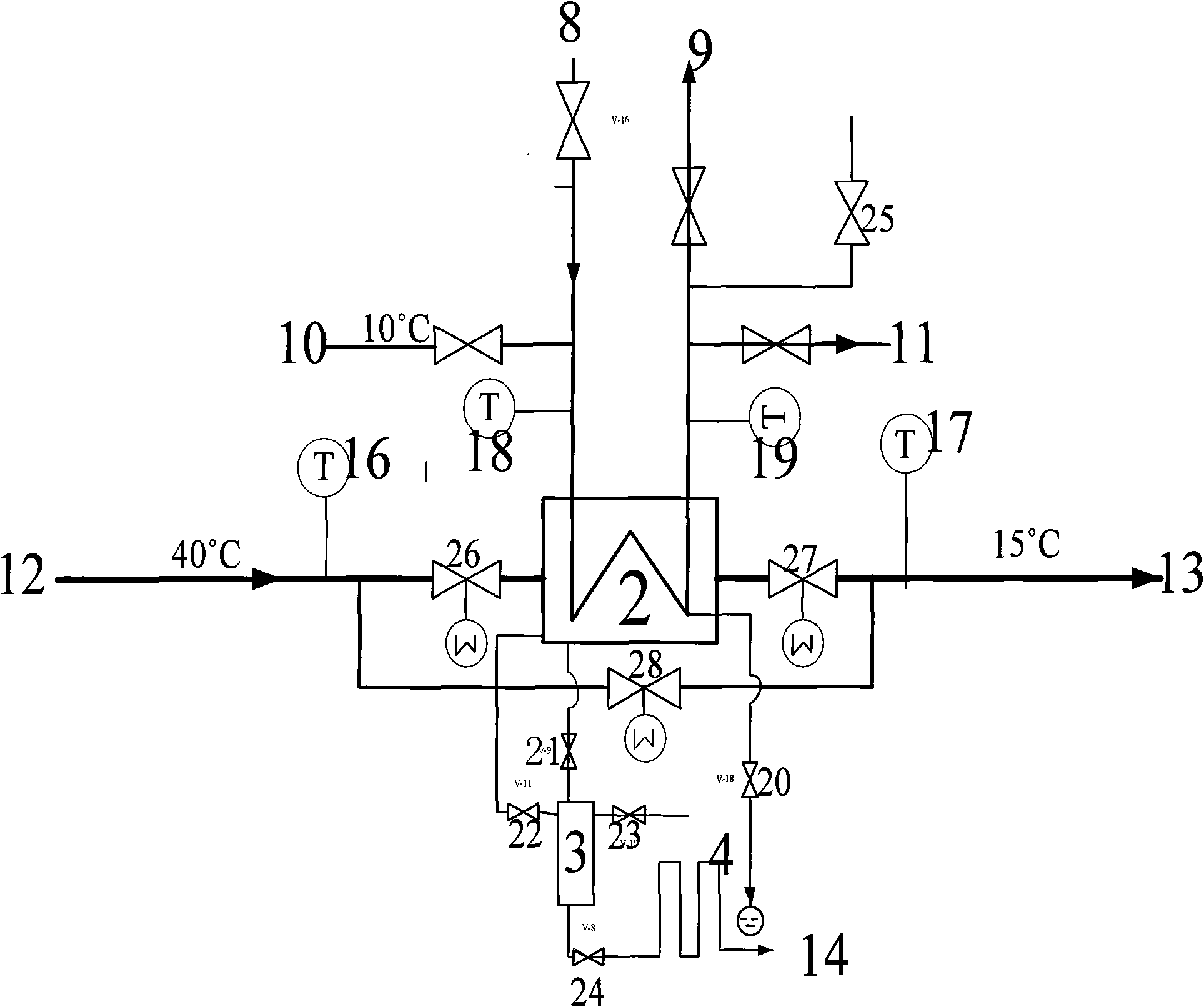

[0026] Such as figure 2 , image 3 , the cooler 2 is installed on the pipeline 7 between the vacuum pump 5 and the condenser 1, and is as close as possible to the vacuum pump inlet valve 6. The gas side inlet 12 of the cooler is connected to the vacuum pumping pipe 7 of the condenser; the gas side outlet 13 of the cooler is connected to the front pipe of the vacuum pump inlet; Road electric door 28; cooler air side installs condensate recovery water storage tank 3, the water storage tank is connected to condenser hot well 14 through water seal 4; cooler water side open water inlet 8 is connected to open water On the water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com