Technology for jointly extracting synephrine, hesperidin and PMFs (polymethoxy latednavones) from fructus aurantii immaturus

A technology of combined extraction and hesperidin, applied in the field of bioseparation engineering, can solve the problems of difficult separation and extraction, no simultaneous extraction and separation, waste of auxiliary materials and heat energy during separation and extraction, and achieve energy consumption reduction, heat energy reduction, and high-efficiency Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

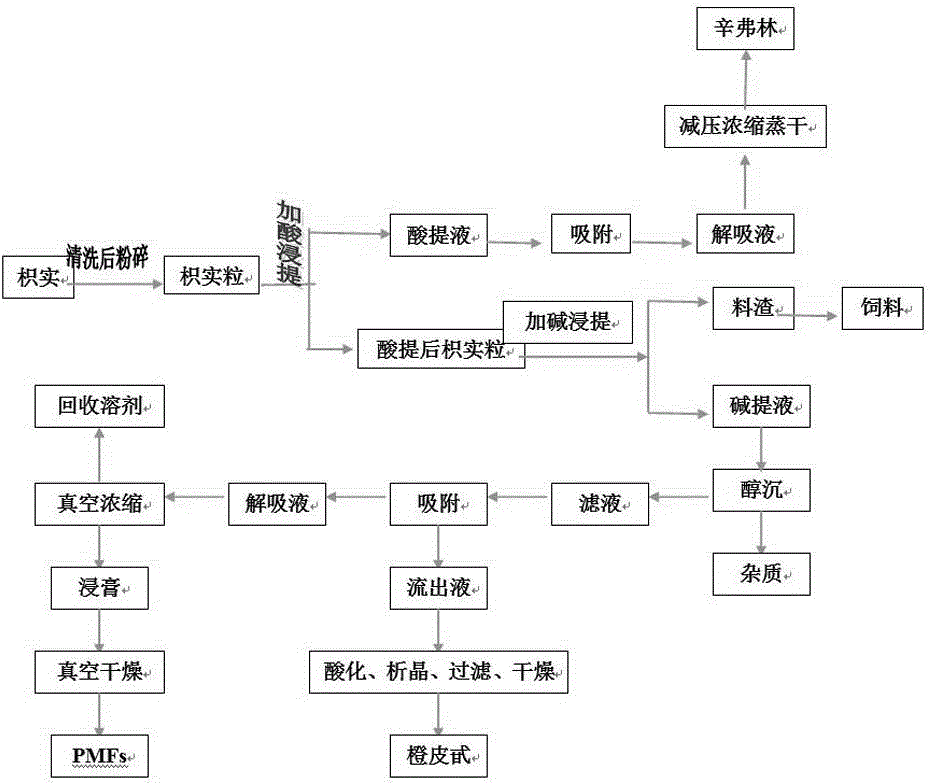

Method used

Image

Examples

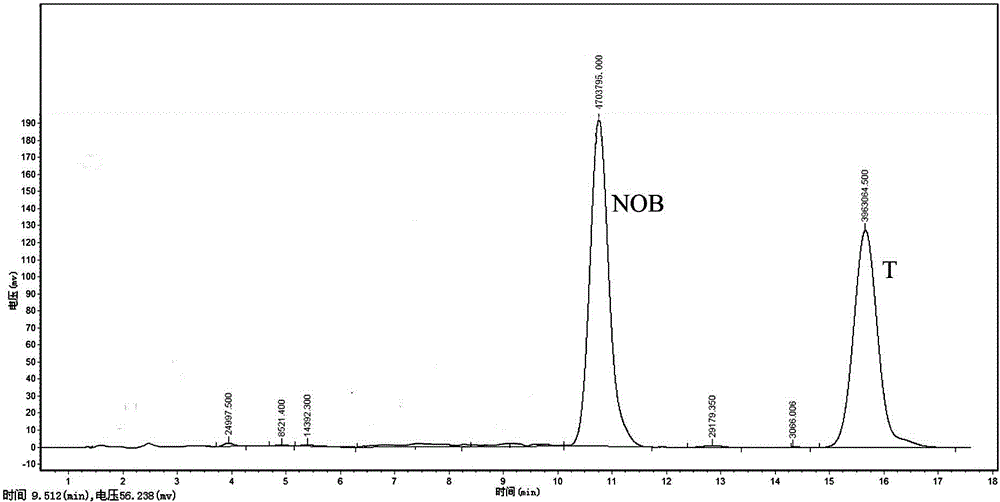

Embodiment 1

[0037] Embodiment 1: The technology that extracts synephrine, hesperidin and PMFs jointly in the citrus aurantium described in the present embodiment is characterized in that comprising the following steps:

[0038] a. Extraction and separation of synephrine

[0039] (1) Sieve 10kg of Citrus aurantium to remove stones, iron nails and other sundries, wash away the sediment, air-dry until soaked, and crush. Equally distributed in two percolation tanks, coded as No. 1 and No. 2.

[0040] (2) First add 100L 0.08% dilute H to No. 1 tank 2 SO 4 The solution is soaked, stirred, and percolated, and the effluent is added to No. 2 tank for the same operation. Add 100L 0.08% dilute H to No. 1 tank 2 SO 4 solution, repeat once, and combine the leachate.

[0041] (3) Concentrate the leachate in (2) to 180L at a vacuum degree of 0.08Mpa and a temperature of 70°C for later use.

[0042] (4) Pretreatment of D001 macroporous resin: Soak 200g of resin in distilled water overnight, drain,...

Embodiment 2

[0053] a. Extraction and separation of synephrine

[0054] (1) Perform step a (1) in Example 1 with 100kg Citrus aurantium.

[0055] (2) First add 1000L 0.08% dilute HCl solution to No. 1 tank for soaking, stirring and diafiltration, then add the effluent to No. 2 tank for the same operation. Then add 1000L 0.08% dilute HCl solution to No. 1 tank, repeat once, and combine the leachate.

[0056] (3) Concentrate the leachate in (2) to 1600L at a vacuum degree of 0.08Mpa and a temperature of 65°C for later use.

[0057] (4) Pretreatment of D061 macroporous resin: Soak 2kg of resin in distilled water overnight, drain, wash with 3% HCl, distilled water, 3% NaOH, distilled water, 3% HCl, and distilled water until neutral, and wet-pack the column .

[0058](5) Pass the leachate in (2) through the chromatographic column to absorb synephrine for 8 hours, then wash with water until the effluent is neutral, desorb with 8% ammonia solution at a rate of 6L / h, and desorb until the efflue...

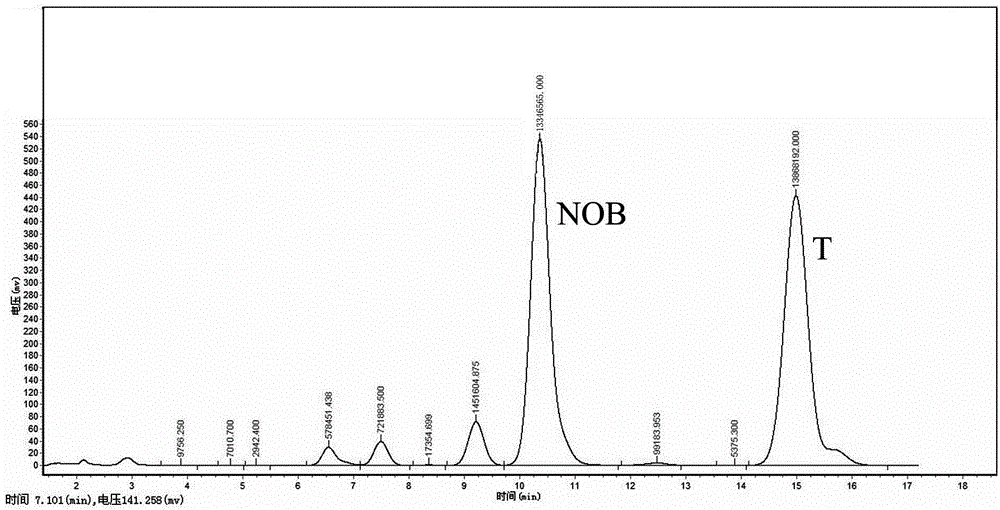

Embodiment 3

[0068] a. Extraction and separation of synephrine

[0069] (1) Perform step a (1) in Example 1 with 1000kg Citrus aurantium.

[0070] (2) First add 10000L 0.2% dilute HCl solution to No. 1 tank for soaking, stirring, and percolation, and then add the effluent to No. 2 tank for the same operation. Then add 10000L 0.2% dilute HCl solution to No. 1 tank, repeat once, and combine the leachate.

[0071] (3) Concentrate the leachate in (2) to 14,000L at a vacuum degree of 0.08Mpa and a temperature of 70°C for later use.

[0072] (4) Pretreatment of D152 macroporous resin: 20kg of resin was treated the same as step (4) of step a in Example 2.

[0073] (5) Pass the leachate in (2) through the chromatographic column to adsorb synephrine for 14 hours, then wash with water until the effluent is neutral, desorb with 10% ammonia solution at a rate of 6L / h, and desorb until the effluent is nearly free up to color. The desorption solution was concentrated at a vacuum degree of 0.085Mpa a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com