Cooling bleaching production technique of white portland cement clinker

A cement clinker cooling and white silicate technology, which is applied in the white Portland cement clinker cooling and bleaching production process, can solve the problems of restricting clinker firing output and quality, and clinker firing heat consumption. Achieve the effects of improving quality, reducing heat consumption, and promoting full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

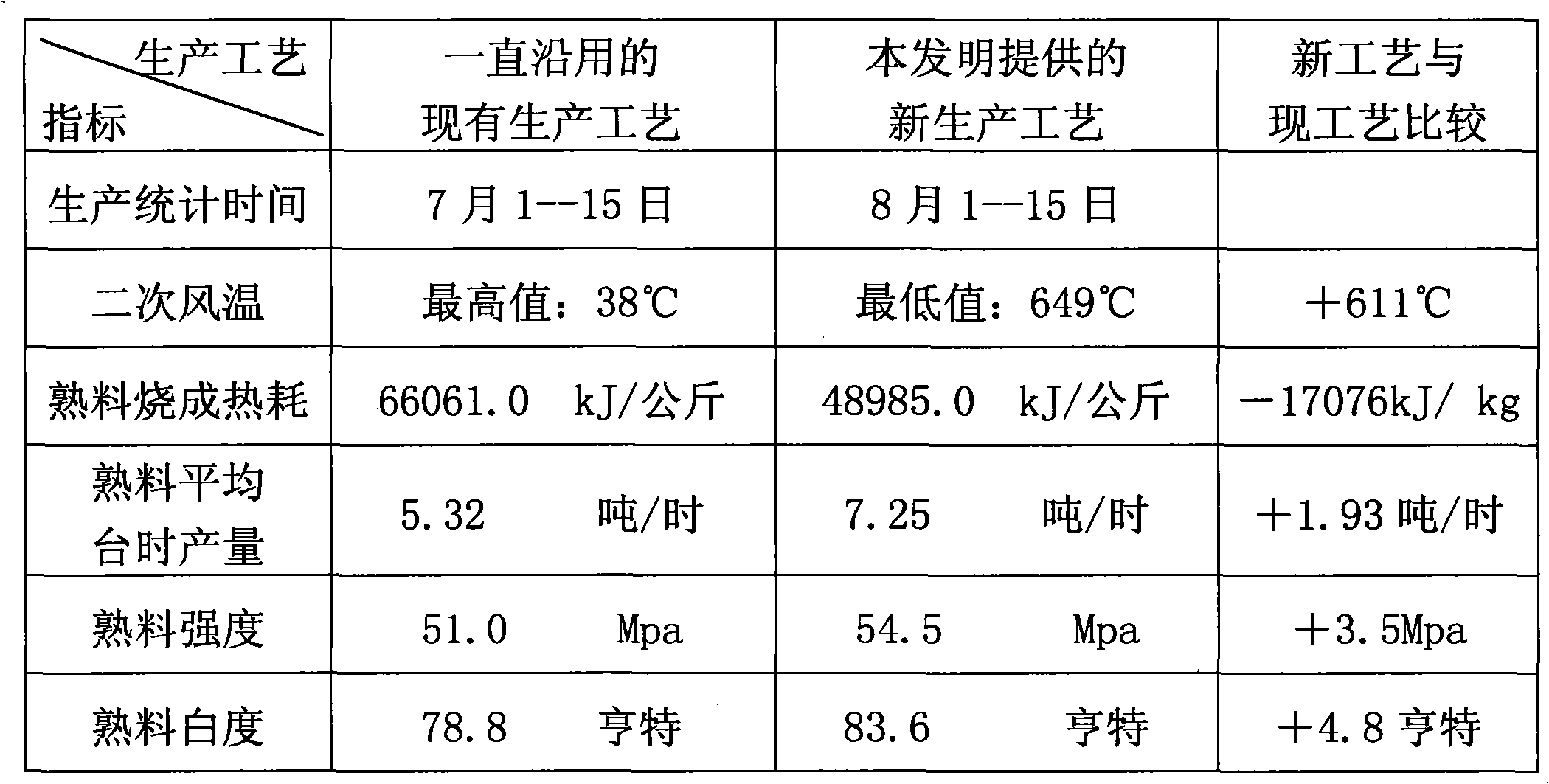

Examples

Embodiment Construction

[0012] A white Portland cement clinker cooling and bleaching production process is to send the calcined high-temperature white Portland cement clinker out of the kiln discharge port into the air heat exchanger first, and the air heat exchanger adopts a The grate cooler uses a fan for 100-200 seconds of air-cooled bleaching to cool down the white Portland cement clinker by 300-400°C, and the hot air after heat exchange with the high-temperature clinker is then sent to the clinker kiln as a secondary Secondary combustion-supporting air, the white Portland cement clinker after being air-cooled and bleached by the air heat exchanger is transferred to a conventional water-spraying or water-immersion cooling bleaching machine for water-spraying or water-immersion cooling and bleaching until the clinker drops to 20-100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com