Method for preparing expanded concrete clinker by utilizing low-grade limestone

A low-grade limestone and expanded clinker technology, applied in the field of comprehensive resource utilization, can solve the irreversible impact of sustainable development of mineral resources and other issues, and achieve the effect of increasing market competitiveness, reducing burning heat consumption, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

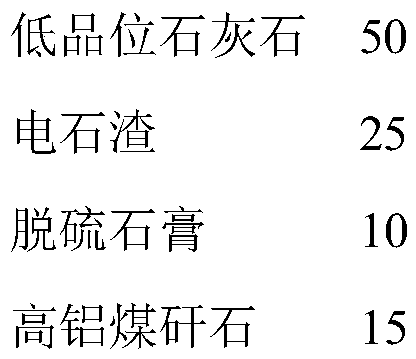

Embodiment 1

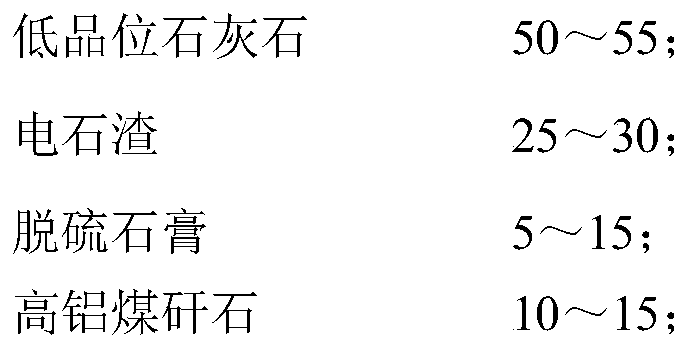

[0042] The concrete expansion clinker of embodiment 1 of the present invention is made up of following raw material by weight part:

[0043]

[0044] The preparation method of the present embodiment 1 concrete expansion clinker comprises the steps:

[0045] ⑴ First, 50 parts of low-grade limestone and 15 parts of high-alumina coal gangue are mixed in proportion and sent to a ball mill for grinding to 200 mesh, and then sent to the mixed material warehouse for storage;

[0046] ⑵Carbide slag is loaded into the feeding box through the loader, and sent to the impeller feeder through the discharge conveyor and belt conveyor, and then the dispersed calcium carbide slag is fed into the cyclone dryer through the disperser, and is separated from the kiln The hot flue gas introduced at the end is fully heat-exchanged, and the dried calcium carbide slag powder is collected by the cyclone dust collector and sent to the calcium carbide slag dry powder warehouse for storage;

[0047] (...

Embodiment 2

[0054] Embodiment 2 of the present invention The concrete expansion clinker consists of the following raw materials in parts by weight:

[0055]

[0056] The preparation method of the present embodiment 2 concrete expansion clinker comprises the steps:

[0057] ⑴ First, 55 parts of low-grade limestone and 10 parts of high-alumina coal gangue are mixed in proportion and sent to a ball mill for grinding to 250 mesh, and then sent to the mixed material warehouse for storage;

[0058] ⑵Carbide slag is loaded into the feeding box through the loader, and sent to the impeller feeder through the discharge conveyor and belt conveyor, and then the dispersed calcium carbide slag is fed into the cyclone dryer through the disperser, and is separated from the kiln The hot flue gas introduced at the end is fully heat-exchanged, and the dried calcium carbide slag powder is collected by the cyclone dust collector and sent to the calcium carbide slag dry powder warehouse for storage;

[005...

Embodiment 3

[0066] Embodiment 3 of the present invention Concrete expansion clinker is made up of following raw material by weight part:

[0067]

[0068] The preparation method of present embodiment 3 concrete expansion clinker comprises the steps:

[0069] ⑴ Firstly, 50 parts of low-grade limestone and 10 parts of high-alumina coal gangue are mixed in proportion and then sent to a ball mill for grinding to 200 mesh, and then sent to the mixed material warehouse for storage;

[0070] ⑵Carbide slag is loaded into the feeding box through the loader, and sent to the impeller feeder through the discharge conveyor and belt conveyor, and then the dispersed calcium carbide slag is fed into the cyclone dryer through the disperser, and is separated from the kiln The hot flue gas introduced at the end is fully heat-exchanged, and the dried calcium carbide slag powder is collected by the cyclone dust collector and sent to the calcium carbide slag dry powder warehouse for storage;

[0071] ⑶ Sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com