Concrete expanding clinker, expanding agent and preparation methods thereof

A technology for expanding clinker and concrete, which is applied in the field of concrete expanding clinker, expansion agent and its preparation, can solve the problems that have not been reported, and achieve the effect of realizing reuse, realizing reuse, and increasing the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

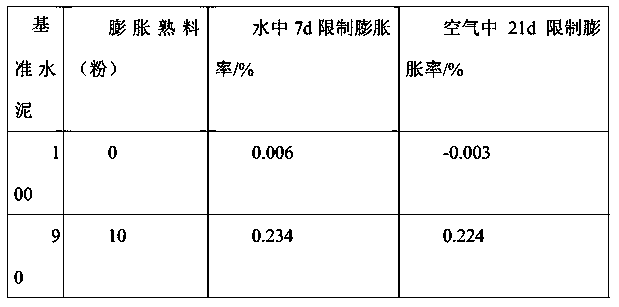

[0032] The concrete expansion clinker of embodiment 1 of the present invention is made up of following raw material by weight part:

[0033]

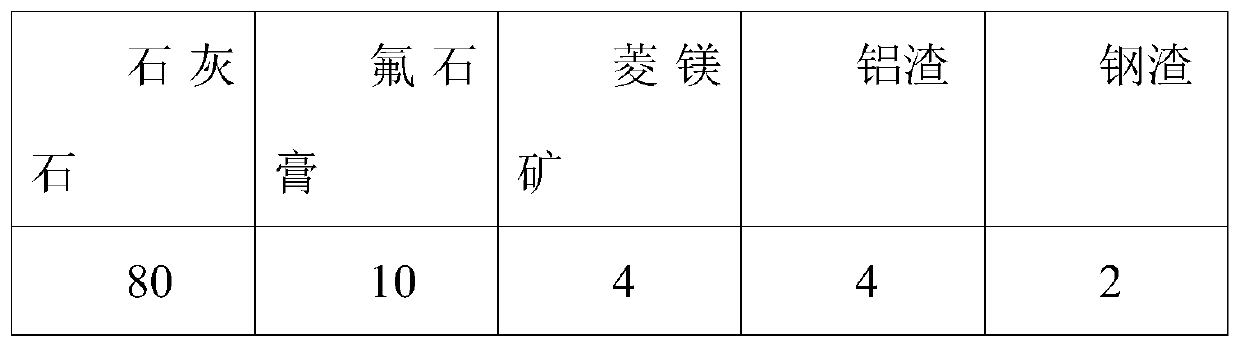

[0034] The preparation method of the present embodiment 1 concrete expansion clinker comprises the steps:

[0035] ⑴ First mix 80 parts of limestone, 10 parts of fluorine gypsum, 4 parts of magnesite, 4 parts of aluminum slag, and 2 parts of steel slag in proportion, then send them into a ball mill for grinding until the sieve residue of 0.08mm is ≤ 30%, and the mixed material is obtained after grinding , and send it to the raw meal storehouse for homogenization and storage;

[0036] (2) The raw meal powder in the raw meal storehouse is transported to the kiln tail steady-flow feeding small warehouse through the storehouse bottom unloading device, the air conveying chute and the bucket elevator, and is fed into the rotary kiln for calcination after being measured by the solid flow meter. The calcination temperature The temperature i...

Embodiment 2

[0050] Embodiment 2 of the present invention The concrete expansion clinker consists of the following raw materials in parts by weight:

[0051]

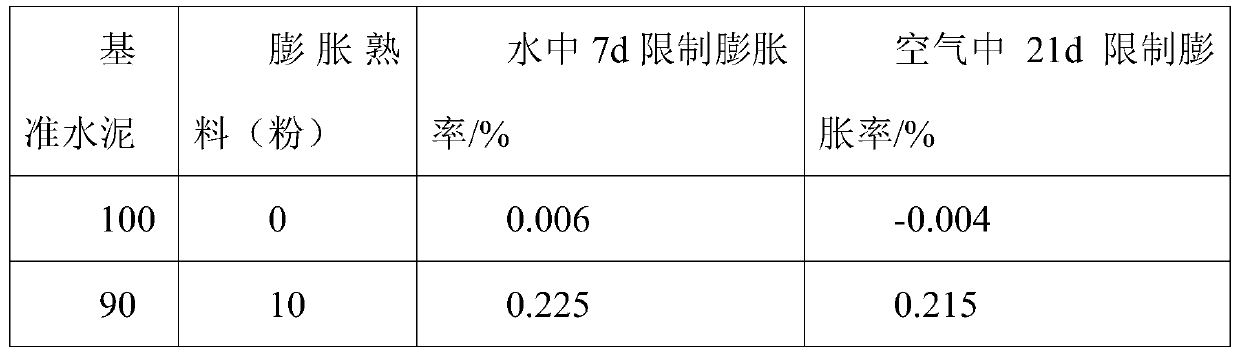

[0052] The preparation method of the present embodiment 2 concrete expansion clinker comprises the steps:

[0053] ⑴ First mix 75 parts of limestone, 15 parts of fluorine gypsum, 4 parts of magnesite, 4 parts of aluminum slag, and 2 parts of steel slag in proportion, and then send them into a ball mill for grinding until the sieve residue of 0.08mm is ≤30%. After grinding, the mixed material is obtained , and send it to the raw meal storehouse for homogenization and storage;

[0054] (2) The raw meal powder in the raw meal storehouse is transported to the kiln tail steady-flow feeding small warehouse through the storehouse bottom unloading device, the air conveying chute and the bucket elevator, and is fed into the rotary kiln for calcination after being measured by the solid flow meter. The calcination temperature The temperatu...

Embodiment 3

[0067] Embodiment 3 of the present invention Concrete expansion clinker is made up of following raw material by weight part:

[0068]

[0069]

[0070] The preparation method of present embodiment 3 concrete expansion clinker comprises the steps:

[0071] ⑴ First mix 70 parts of limestone, 18 parts of fluorine gypsum, 5 parts of magnesite, 5 parts of aluminum slag, and 2 parts of steel slag in proportion, then send them to the ball mill for grinding until the sieve residue of 0.08mm is ≤ 30%, and the mixed material is obtained after grinding , and send it to the raw meal storehouse for homogenization and storage;

[0072] (2) The raw meal powder in the raw meal storehouse is transported to the kiln tail steady-flow feeding small chamber through the storehouse bottom unloading device, the air conveying chute, and the bucket elevator, and is fed into the rotary kiln for calcination after being measured by the solid flow meter. The temperature is 1250°C-1400°C, and the cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com