A kind of magnesia expansion agent prepared by using high-calcium magnesite tailings and its preparation method

A technology of high-calcium magnesite and mine tailings, applied in the field of preparation of expansion agent, can solve the problems of secondary environmental pollution, high cost, complicated treatment process, etc., and achieve the effect of reducing production cost and significant social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

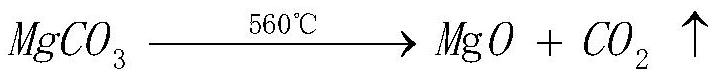

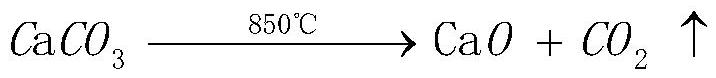

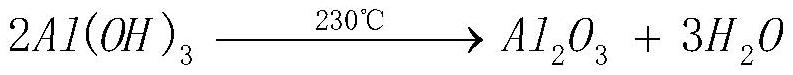

Method used

Image

Examples

Embodiment 1

[0029] First, 92 parts of high-calcium magnesite tailings and 8 parts of aluminum hydroxide are mixed according to the proportion and then ground together to 250 mesh to make raw meal powder, and then the raw meal powder after grinding is heated at 1000 °C Calcined under high temperature, and kept at this temperature for 80 minutes, after the heat preservation was completed, the calcined material was taken out to cool in the air, and finally the cooled calcined material was ground to a specific surface area of 350m 2 / kg, a kind of magnesium expansive agent HME-1 prepared by utilizing high-calcium magnesite tailings of the present invention is obtained.

Embodiment 2

[0031]First, 95 parts of high-calcium magnesite tailings and 5 parts of aluminum hydroxide are mixed according to the proportion, and then they are jointly ground to 300 mesh to make raw meal powder, and then the raw meal powder after grinding is heated at 1050°C Calcined under high temperature, and kept at this temperature for 60 minutes, after the heat preservation was completed, the calcined material was taken out to cool in the air, and finally the cooled calcined material was ground to a specific surface area of 300m 2 / kg, a kind of magnesia expansion agent HME-2 prepared by utilizing high-calcium magnesite tailings of the present invention is obtained.

Embodiment 3

[0033] First, 90 parts of high-calcium magnesite tailings and 10 parts of aluminum hydroxide are mixed according to the proportion, and then they are jointly ground to 280 mesh to make raw meal powder, and then the raw meal powder after grinding is heated at 950°C Calcined under high temperature, and kept at this temperature for 90 minutes, after the heat preservation was completed, the calcined material was taken out to cool in the air, and finally the cooled calcined material was ground to a specific surface area of 400m 2 / kg, a kind of magnesia expansion agent HME-3 prepared by utilizing high-calcium magnesite tailings of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com