Patents

Literature

32results about How to "Gelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

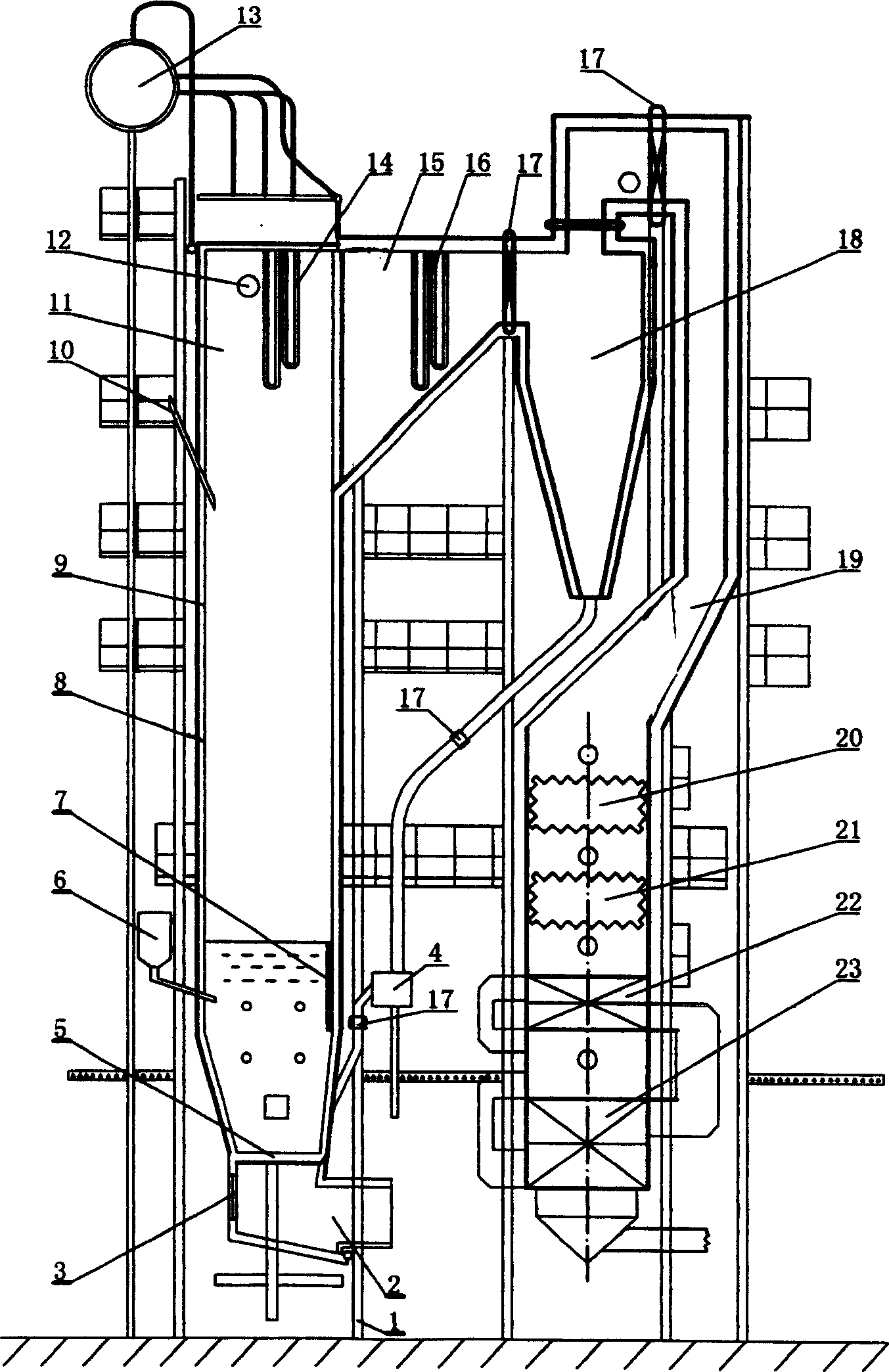

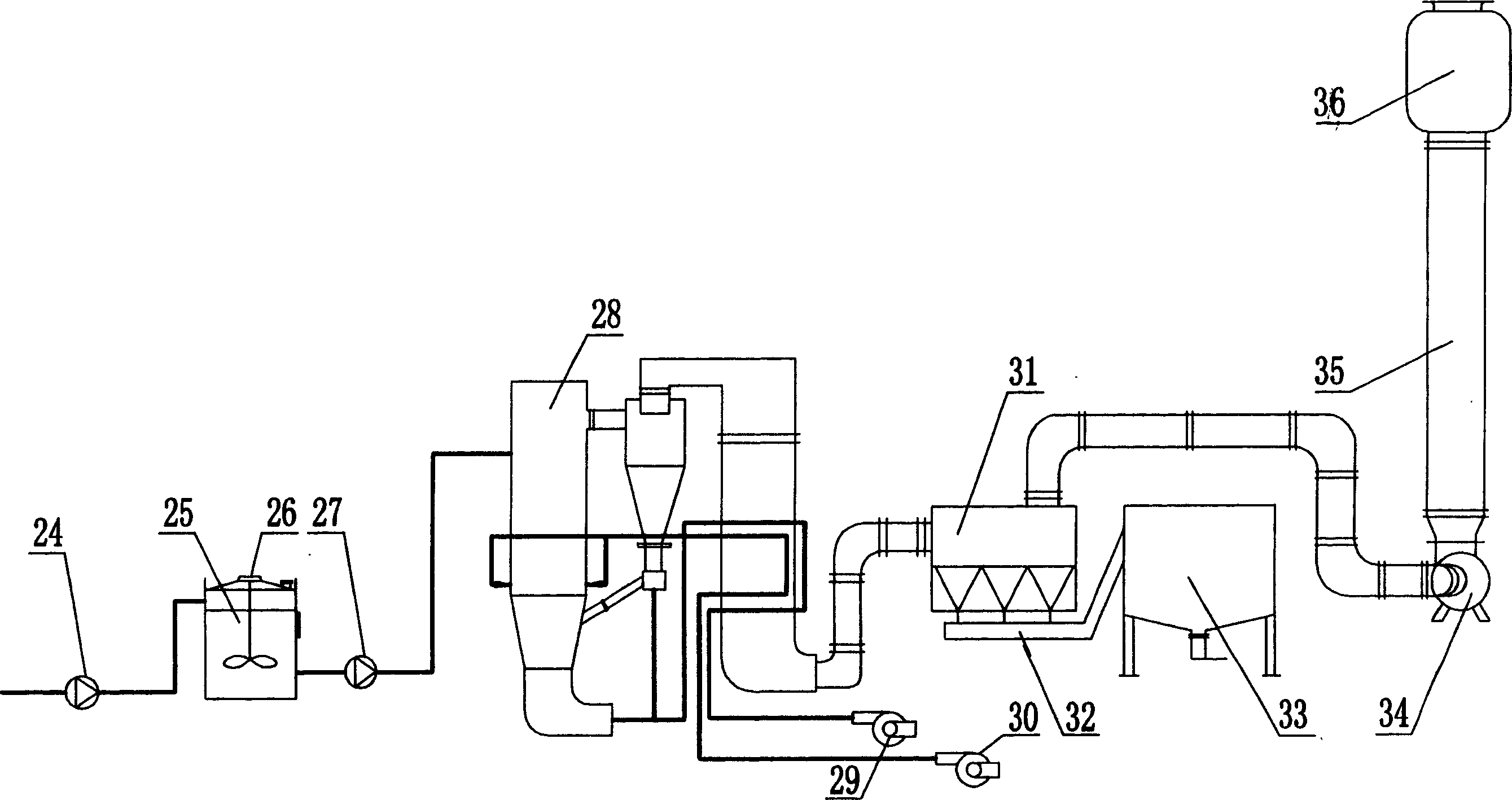

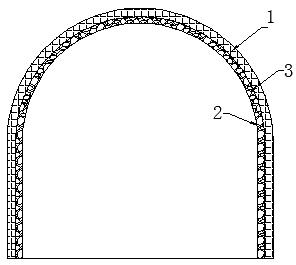

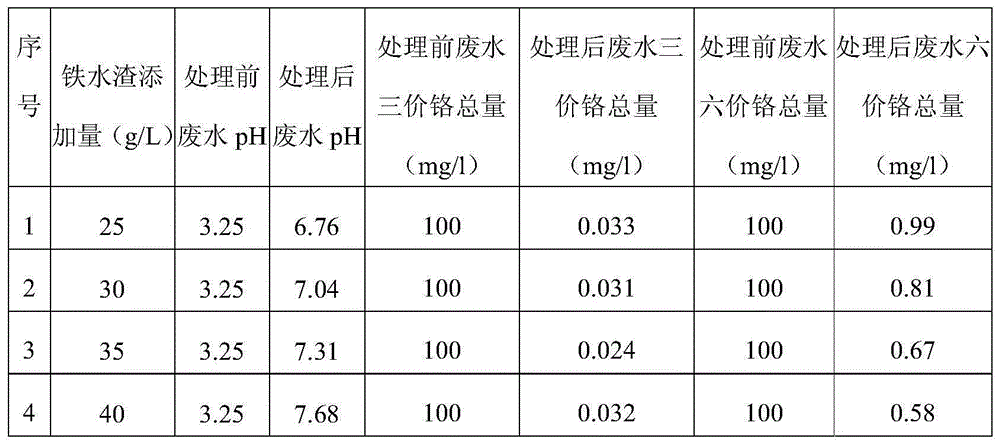

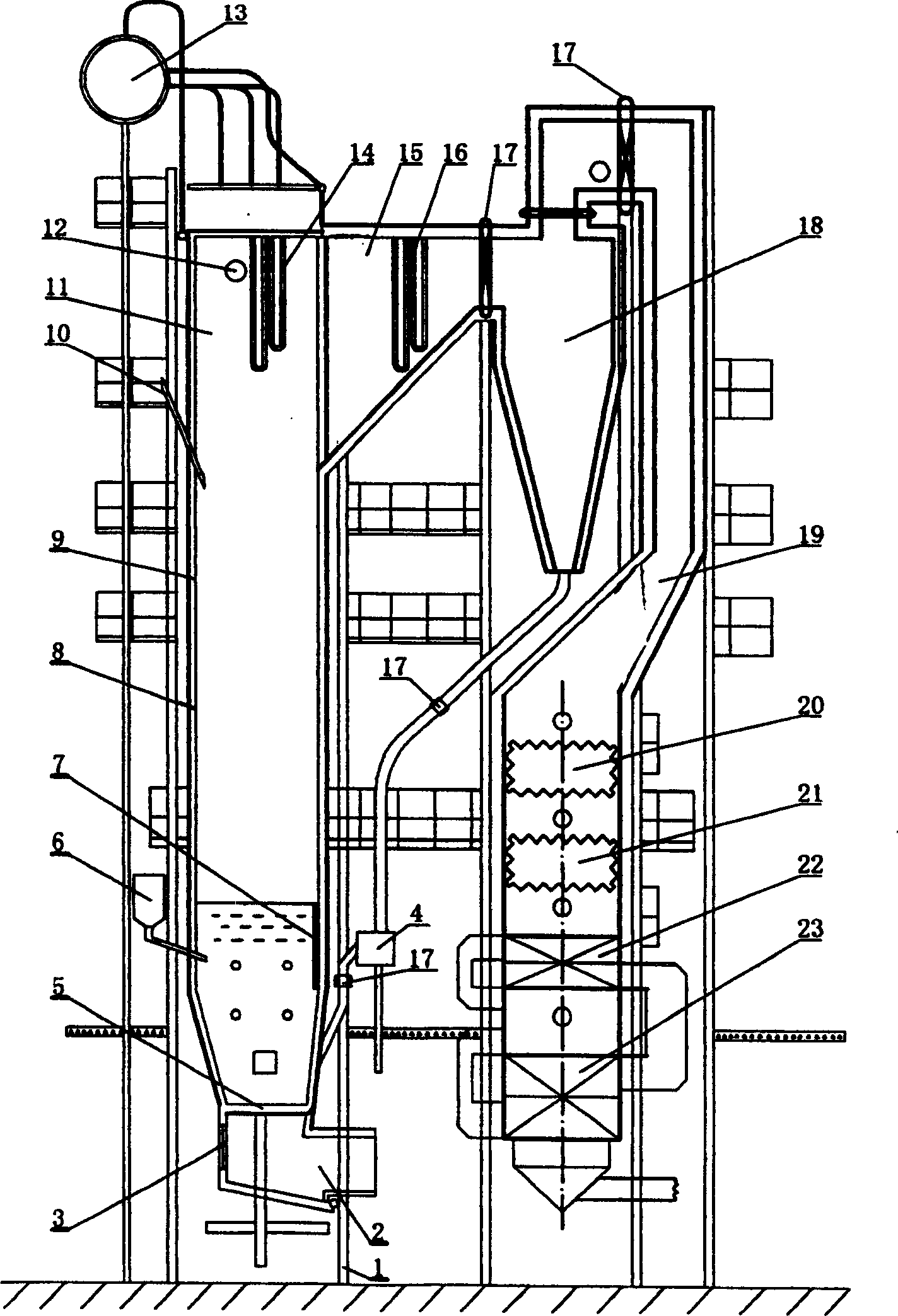

Oil field steam filling boiler of circulation fluidized bed using water coal slurry as fuel

InactiveCN1563793ACurb emissionsRealize direct desulfurizationFluidized bed combustionApparatus for fluidised bed combustionWear resistantEngineering

The oil well gas injecting boiler has screw pump in pressure of 0.2-0.4 MPa to supply fuel from the upper part of the boiler, single steam drum in naturally circulating mode to obtain high pressure steam of 17.5-21 MPa; quartzite and limestone powder as fuidizing medium for low multiplying factor circulation; and power amount of limestone powder for clean burning at temperature of 850-950 deg.c. The boiler of the present invention has water cooling furnace wall, coated heat resistant and corrosion resistant refractory material and sprayed heat resistant and wear resistant Ni-Cr alloy, pipe type backwards bent boiler top, coal economizer of ribbed spiral pipes, cyclonic separator with wear resistant material, water cooling wall with inner thread pipe, high temp alloy steel material in high temperature and high pressure sections, welded support frame structure, flexible 3D expanding section in important joint part, and hydrostats.

Owner:SHENYANG DAVID ENVIRONMENT PROTECTION & ENERGY SAVING EQUIP LTD

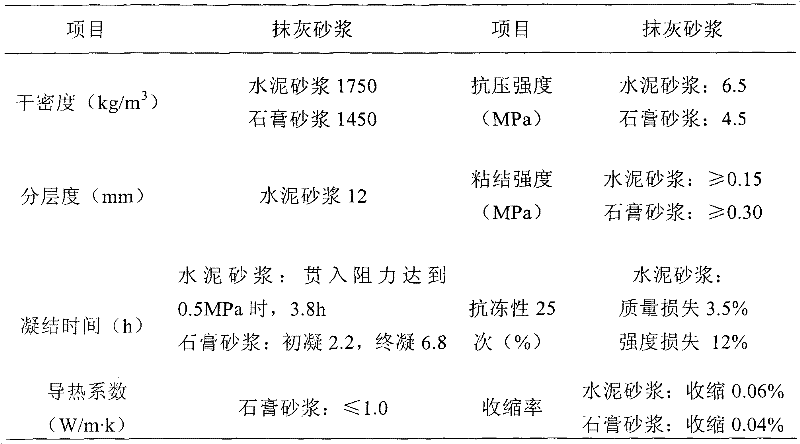

Environment-friendly high-performance waterproof flame-retardant plastering mortar and preparation method thereof

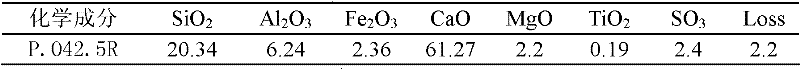

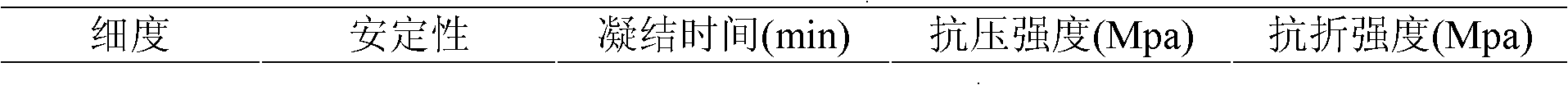

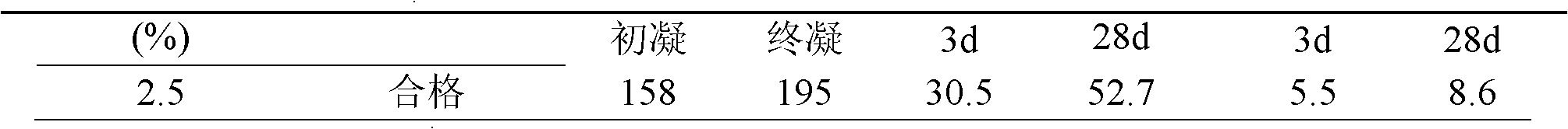

The invention relates to environment-friendly high-performance waterproof flame-retardant plastering mortar, which is prepared by mixing the following components of: P.O42.5R cement, modified phosphogypsum, redispersible latex powder, limestone powder, ceramic microspheres, modified expandable graphite, a water-retaining agent, a toughening agent and a water repellent in a mass ratio of (1-2):(0.4-0.9):(0.1-0.4):(0.1-0.5):(0.5-1):(0.25-1.5):(0.005-0.04):(0.005-0.01):(0.005-0.03). The environment-friendly high-performance waterproof flame-retardant plastering mortar has a great significance for high-efficiency flame retardance, heat insulation, water prevention, permeation resistance, composite heat preservation, energy conservation, the recycling of the phosphogypsum and the reduction in the pollution of solid wastes to environment, and has the advantages of low cost and high strength.

Owner:WUHAN UNIV OF TECH

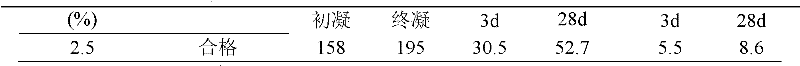

Method for preparing hydraulic cementing material by utilizing sulfur fixation ash

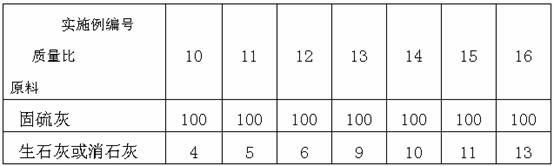

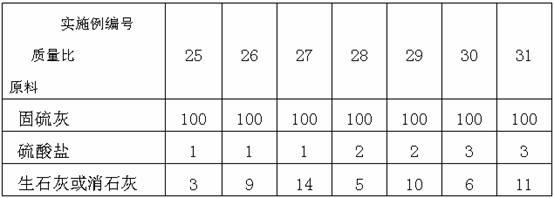

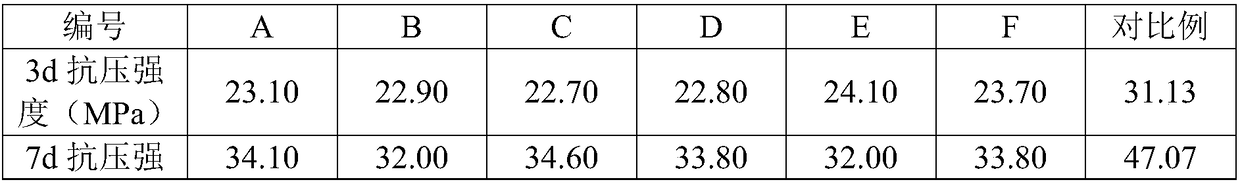

The invention discloses a method for preparing a hydraulic cementing material by utilizing sulfur fixation ash. The method is characterized by comprising the following steps of grinding raw materials, namely grinding the sulfur fixation ash serving as a raw material until the fineness (d50) of the sulfur fixation ash is less than or equal to 14 mu_m, and grinding calcined lime serving as another raw material until the fineness of the calcined lime is 80 mu_m and the screening residue of a standard screen is less than or equal to 10 percent; burdening, namely taking the raw materials according to a proportion that every 100 parts by weight of sulfur fixation ash is doped with 3 to 14 parts by weight of calcined lime or slaked lime or 1 to 3 parts by weight of CaSO4.2H2O; mixing the raw materials, namely uniformly mixing and stirring the raw materials, thus obtaining the hydraulic cementing material. According to the method, waste is turned into wealth, so that environment pollution is reduced; and the hydraulic cementing material prepared by the method can be used as a component of cement concrete, artificial aggregate, a steamed building block, a filling structure and a roadbed and has the advantage of high performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Low hydration heat copper slag based composite cementitious material and preparation method thereof

The invention provides a low hydration heat copper slag based composite cementitious material and a preparation method thereof. The low hydration heat copper slag based composite cementitious materialcomprises the following components by weight: 20-30 parts of copper slag powder; and 70-80 parts of Portland cement; with a total of 100 parts. The preparation method of the low hydration heat copperslag based composite cementitious material includes: step 1: putting copper slag in an oven for 3-4h, and setting the oven temperature at 110DEG C to obtain dried copper slag; step 2: putting the copper slag in a ball mill for powder milling for 30-120min to obtain copper slag powder with a specific surface area of 500-750m<2> / kg; step 3: by weight, adding 20-30 parts of the copper slag powder into 70-80 parts of Portland cement, and stirring the substances evenly to obtain the low hydration heat copper slag based composite cementitious material. While ensuring the quality of the cementitiousmaterial, the method improves the copper slag utilization rate, improves the environmental pollution, and reduces the energy consumption and cost of cement calcination.

Owner:JIANGXI UNIV OF TECH

Synergetic preparation of industrial waste gypsum mortar with industrial exhaust gas and toxicity solution

The invention discloses a synergetic preparation of industrial waste gypsum mortar with industrial exhaust gas and a toxicity solution. Lingering warmth in the industrial exhaust gas is used for converting dihydrate gypsum in industrial waste gypsum into hemihydrate gypsum to prepare desulfurized gypsum binding material. According to the solution,the industrial waste gypsum and tailing sand are used as basic raw materials, waste heat of the industrial waste gas is used for making the industrial waste gypsum higher in gelling property, the simultaneouslyadded diammonium hydrogen phosphate and calcium ions in the industrial waste gypsum generate hydroxyapatite, the mechanical property of the industrial waste gypsum-based bindingmaterialcan be significantlyimproved, at the same time, OH-groupin the hydroxyapatite can be replaced by fluoride, chloride, and carbonate ions to form fluoroapatite or chloroapatite,the calcium ions are replaced through ion exchange reaction by a variety of metal ions to form M apatite corresponding to the metal ions, harmful substances dissolved in the industrial waste gypsum and the tailing sand are absorbed, and the problem of toxicity can be effectivelysolved.

Owner:SHANDONG UNIV

Hydrogel sustained-release carrier for oral drugs as well as preparation method and application of hydrogel sustained-release carrier

InactiveCN106109400AImprove performanceHigh natural yieldAerosol deliveryDigestive systemPolyvinyl alcoholPharmaceutical formulation

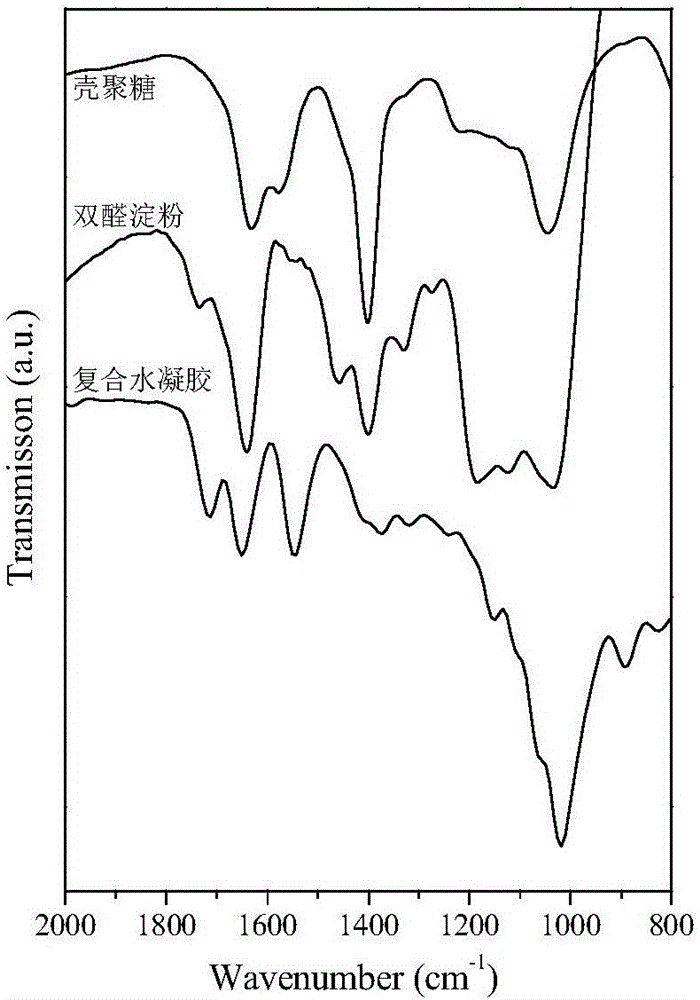

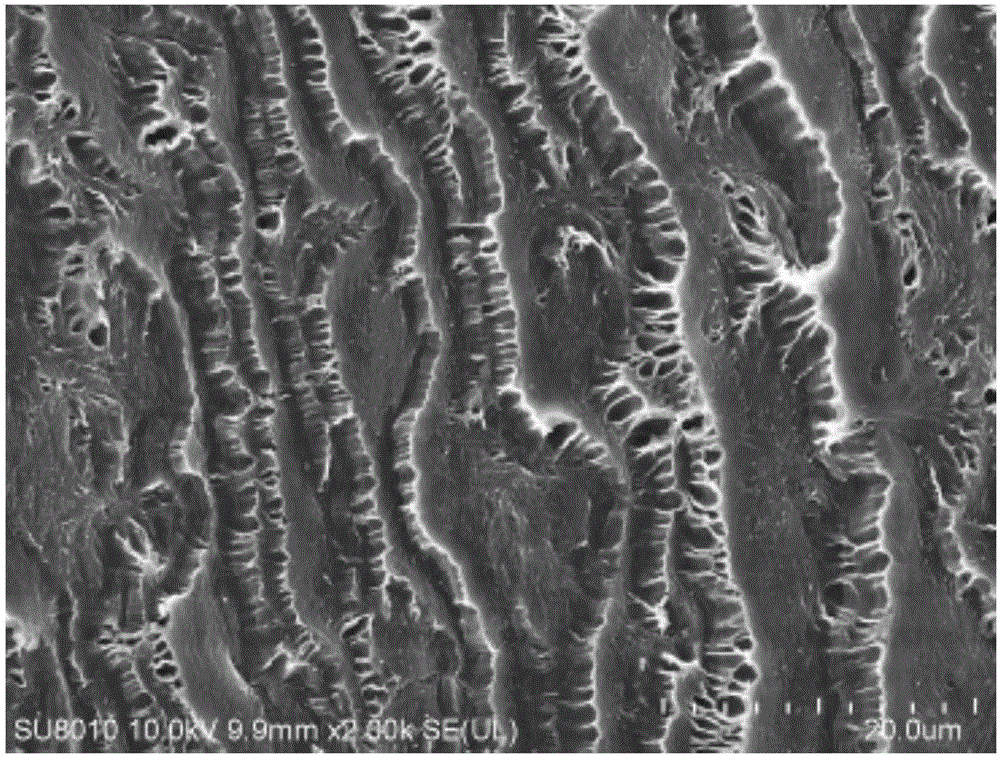

The invention discloses a hydrogel sustained-release carrier for oral drugs as well as a preparation method and an application of the hydrogel sustained-release carrier, and belongs to the technical field of pharmaceutical preparations. A homogeneous solution is obtained by mixing such raw materials as chitosan, dialdehyde starch, gelatin and polyvinyl alcohol according to proportions, and the homogeneous solution, when orally taken into a stomach, can rapidly form a gel so as to take covering and sustained-release effects on the carrier drugs; therefore, the hurt of a high-drug concentration to a receptor is relieved. The drugs, which can achieve sustained release in the stomach, is especially suitable for treating gastric diseases.

Owner:JINLING INST OF TECH

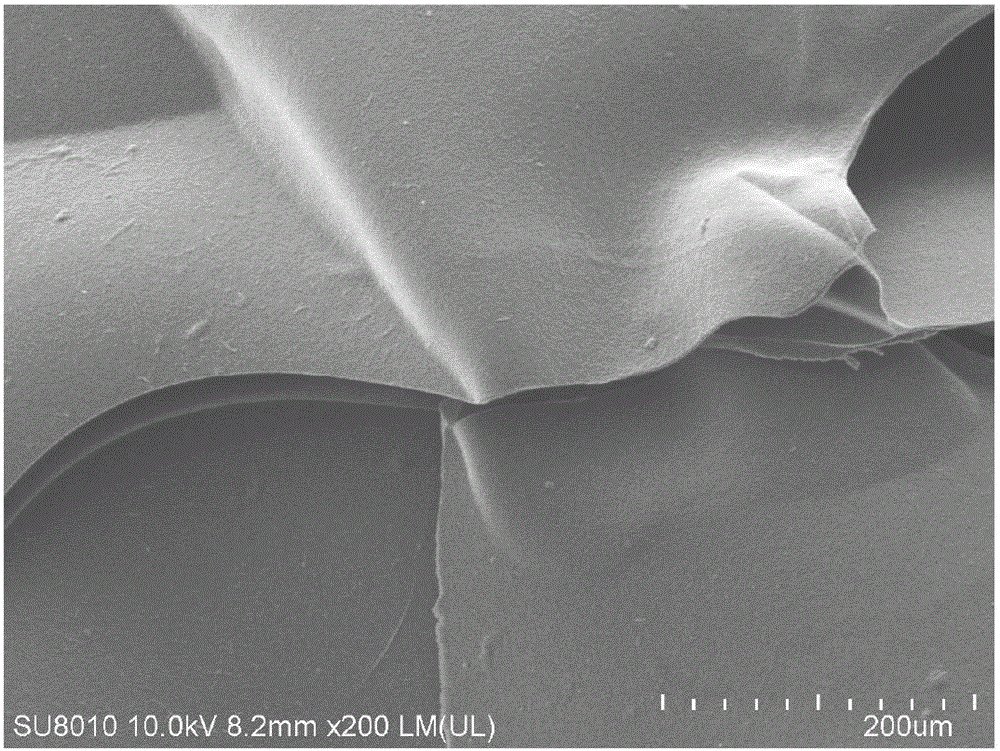

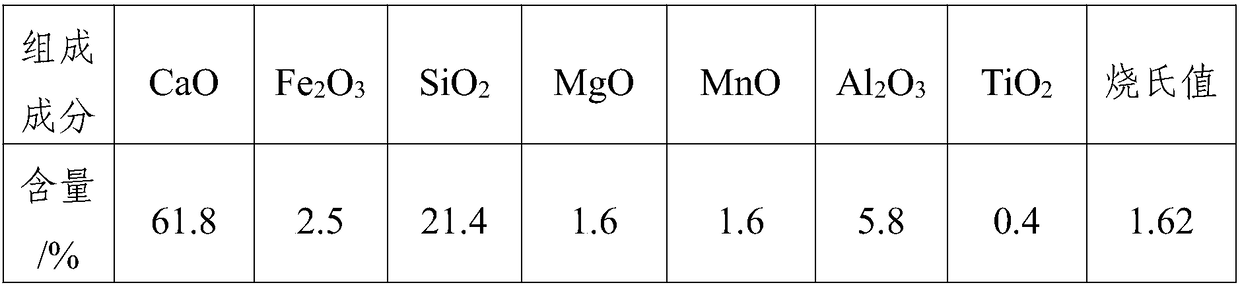

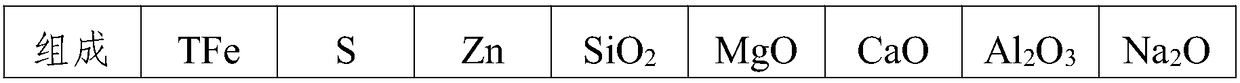

Jarosite slag concrete and preparation method

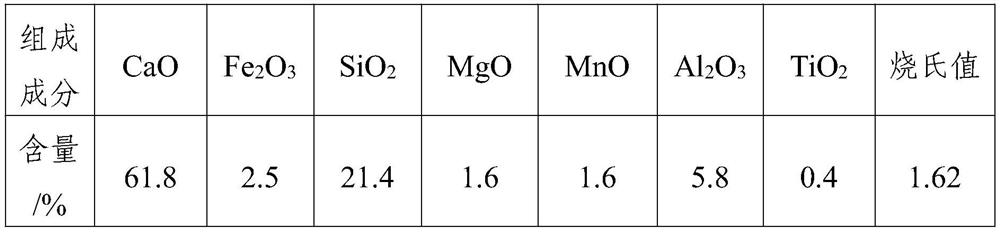

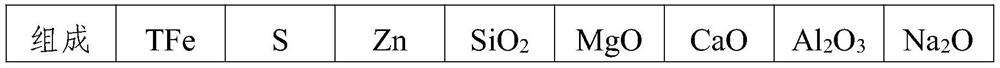

The invention provides jarosite slag concrete and a preparation method, and relates to the technical field of building materials. The method comprises the steps that jarosite slag containing oxides such as CaO, SiO2 Al2O3 is similar to concrete in chemical component so that the jarosite slag can be used for partially replacing cement in the concrete, the jarosite slag, ordinary Portland cement, fine aggregate, coarse aggregate and water are used for preparing different types of concrete, 11-15 parts by weight of water, 16-31 parts by weight of cement, 4-13 parts by weight of jarosite slag, 104-129 pats by weight of coarse aggregate and 60-74 parts by weight of fine aggregate are mixed, and 0-2.5 parts by weight of water is added; generally, a zinc smelting plant can pile up a large amountof jarosite slag, the piling up processing difficulty is great, and meanwhile the environment is polluted. The jarosite slag can be used for preparing concrete products with different strength grades,and engineering application is wide.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

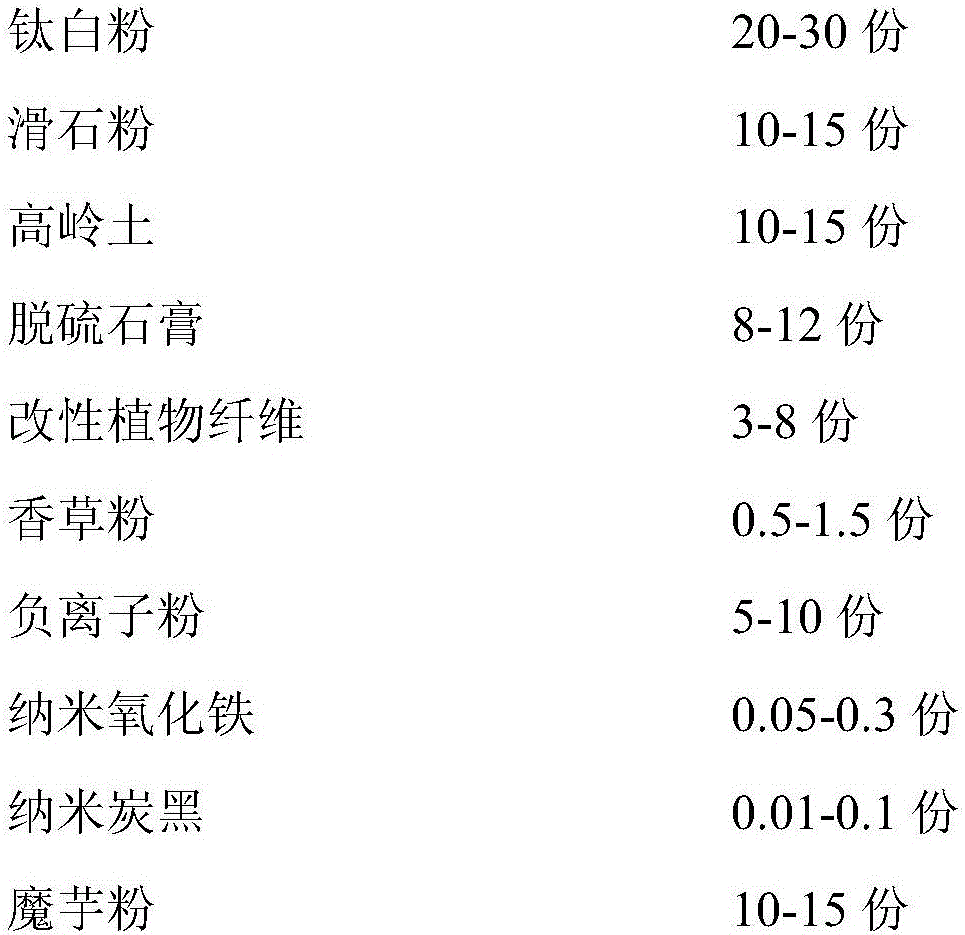

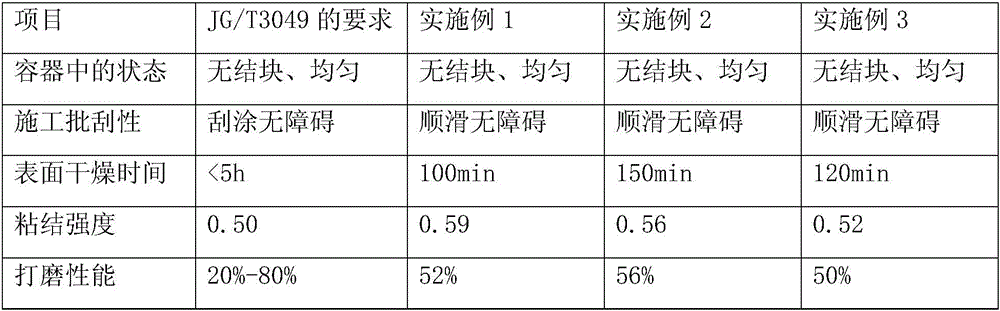

Mimic ecological odor-less spackling compound

The invention relates to a building decoration material, and relates to a mimic ecological odor-less spackling compound. The spackling compound is prepared from, by weight, 20-30 parts of titanium dioxide, 10-15 parts of talcum powder, 10-15 parts of kaolin, 8-12 parts of desulfurization gypsum, 3-8 parts of modified plant fiber, 0.5-1.5 parts of vanilla powder, 5-10 parts of negative ion powder, 0.05-0.3 parts of nanocrystalline iron oxide, 0.01-0.1 part of nano-carbon black, 10-15 parts of konjaku flour and 30-40 parts of water. The obtained mimic ecological odor-less spackling compound has the advantages of being environmentally friendly, capable of optimizing the environment, simple in construction, high in strength, free of peeling and dusting, natural, fresh, simple in use method and the like, and has good market application prospects.

Owner:杭州唯曦科技有限公司

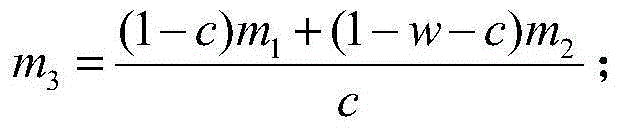

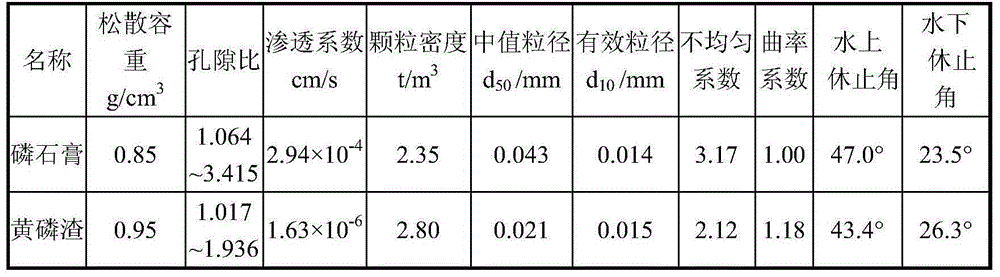

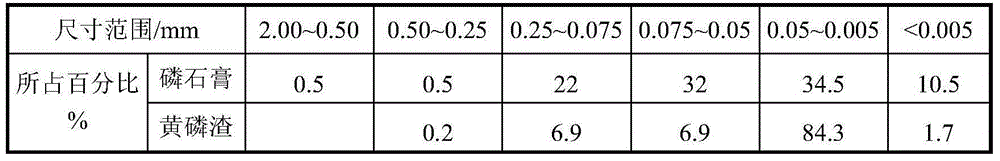

A low bleeding rate pumpable phosphogypsum and yellow phosphorus slag filling paste and its preparation method

The invention relates to a low-bleeding-rate pumpable phosphogypsum and yellow phosphorus slag filling paste and a preparation method of the paste. The paste is prepared by adding a certain percentage of yellow phosphorus slag as a cementing material into industrial waste residue phosphogypsum as a filling aggregate, calculating the required amount of water according to the target concentration on the basis that the natural moisture content of the phosphogypsum is determined, adding water and stirring. The filling paste has the advantages of precise concentration control, relatively low bleeding rate, relatively good fluidity, certain early strength and relatively good middle-term strength and long-term strength, and is used for the paste filling of phosphorite underground mined-out areas; the bleeding rate of slurry for phosphogypsum underground cementing filling is reduced, cost of underground drainage and filling is lowered and the pollution to the mine water environment is reduced. According to the invention, the industrial waste residue phosphogypsum and yellow phosphorus slag can be fully and effectively utilized, requirements on filling operation of phosphorus resource mining are met, the production capacity of a mine is enlarged, economic benefits are increased, the ground accumulation of industrial waste residue is reduced, the occupancy rate of land is lowered and the secondary pollution of filling wastewater to the environment can be effectively reduced.

Owner:CENT SOUTH UNIV

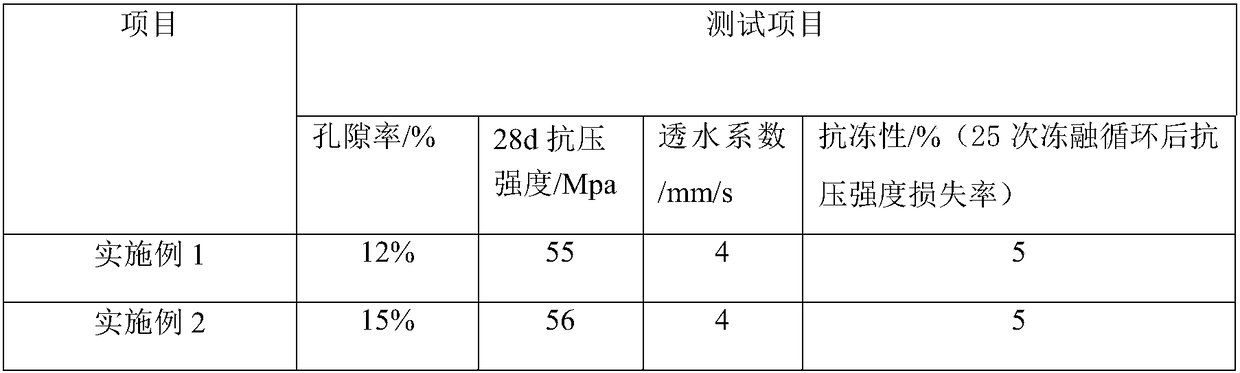

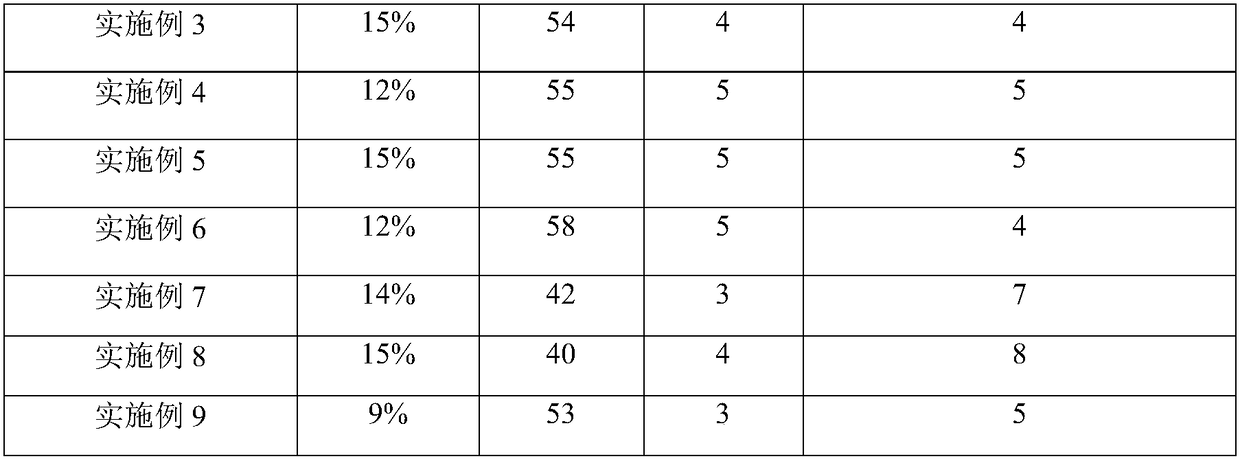

Pervious concrete and preparation method thereof

InactiveCN108191335AHigh strengthGuaranteed StrengthCeramicwareFreeze and thawConstruction aggregate

The invention discloses pervious concrete and a preparation method thereof, and belongs to the technical field of a building material. The pervious concrete is prepared from the following raw materials in proportion by weight: 200 to 300kg / m<3> of ordinary Portland cement, 1250 to 1350kg / m<3> of coarse aggregate, 150 to 280kg / m<3> of mineral admixtures, 10 to 15kg / m<3> of EVA emulsion, 5 to 10kg / m<3> of enhancers and composite anti-freezing agents, wherein the weight of the composite anti-freezing agents account for 1 to 2.5 percent of the total weight of the concrete; the water cement ratio of the concrete is 0.2 to 0.31; the composite anti-freezing agents are prepared from triethanolamine, sulfamate and lignosulphonate according to a mass ratio of (5 to 8):(1 to 2):(1 to 2). The perviousconcrete has the advantages that a good pervious effect is achieved; the compressive strength is high; the freezing and thawing resistant performance is good.

Owner:湖北恒利建材科技有限公司

Environment-friendly lubricating agent for printing ink

InactiveCN106280681ASimple production processImprove the lubrication effectInksEngineeringPrinting ink

An environment-friendly lubricating agent for printing ink is characterized by being prepared from, by weight, 40-60 parts of methacrylic acid, 5-10 parts of emulgator, 4-8 parts of cera alba, 2-3 parts of cinnamaldehyde diethylacetal, 2-3 parts of defoaming agent, 6-10 parts of zein, 0.4-0.6 part of cattlehide powder, 0.1-0.2 part of paeonol, 0.4-0.6 part of radix sophorae flavescentis gel, 0.4-0.6 part of alanine, 3-5 parts of dihydroxy acetone and 1-3 parts of nano bamboo charcoal powder. The zein is used for producing the environment-friendly lubricating agent for printing ink, which is pioneering in China; the lubricating agent prepared through the method has the good characteristics of gelation performance, oxidization resistance and lubricity.

Owner:JIESHOU XINWANG COLOR PRINTING PACKING CO LTD

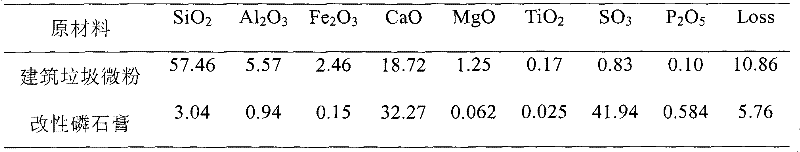

Plastering mortar prepared by using construction wastes and phosphogypsum

The invention relates to a plastering mortar, which is mainly prepared from the following raw materials in percentage by mass: 10 to 20 percent cement, 20 to 30 percent modified phosphogypsum, 20 to 30 percent of construction wastes, 30 to 40 percent of sand, and 3 to 5 percent of exciting agent. A method for preparing the plastering mortar comprises the steps of preparing the modified phosphogypsum, preparing construction waste powder, preparing the exciting agent and preparing a final product. The plastering mortar is of great significance for efficiently utilizing the construction wastes, reducing pollutions caused by solid wastes to the environment and reducing the production cost, and simultaneously the plastering mortar has the advantage of low cost and high strength.

Owner:WUHAN UNIV OF TECH

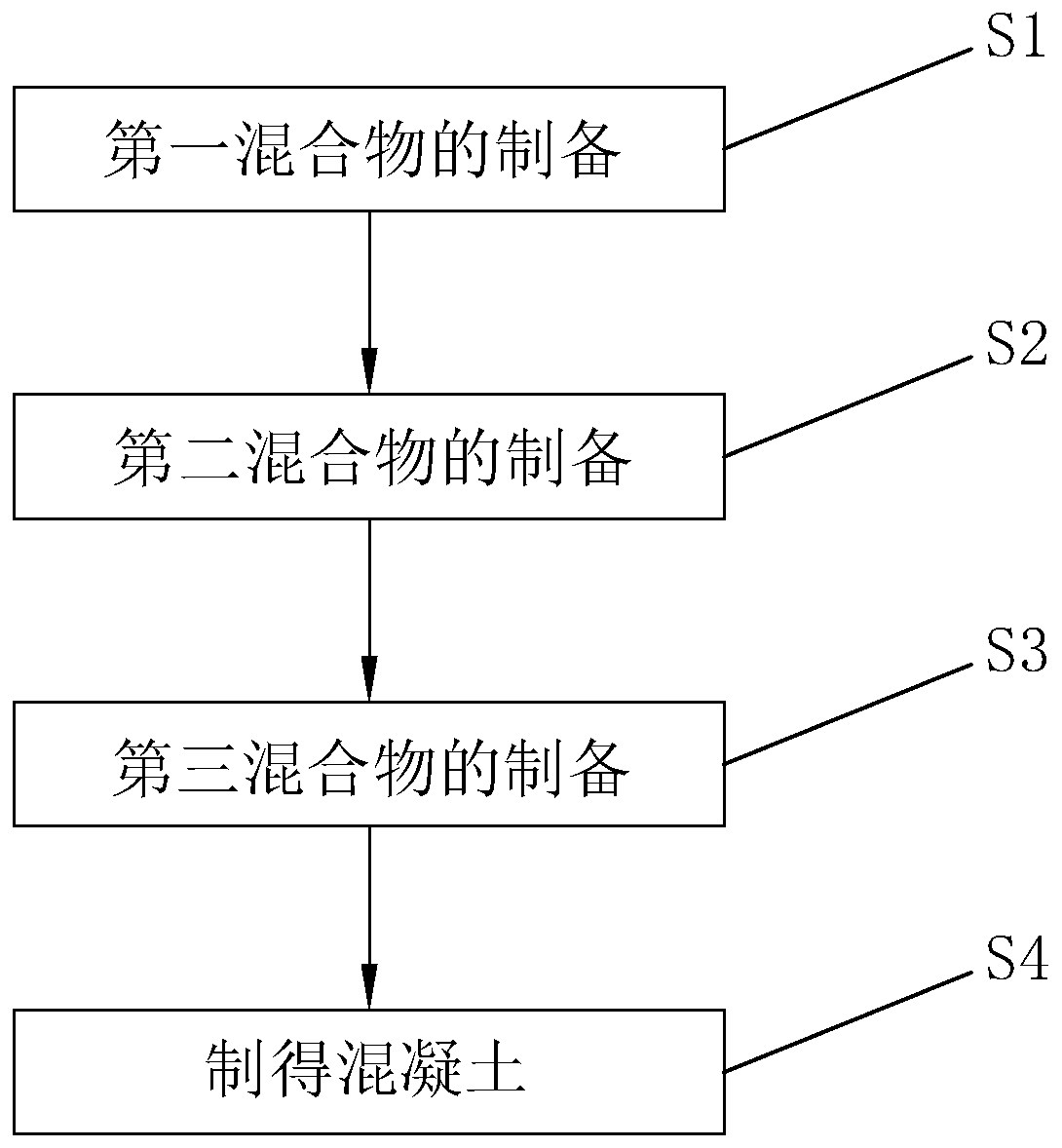

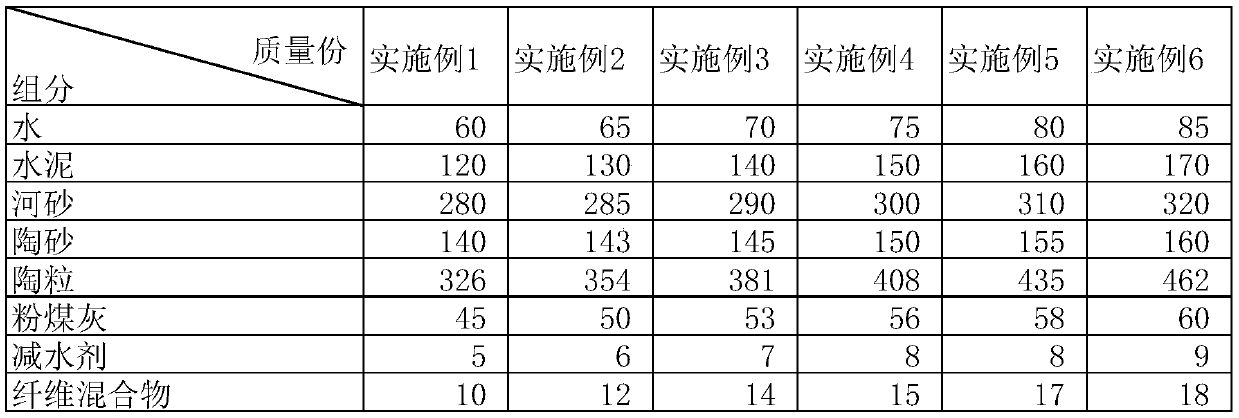

Concrete and preparation method thereof

The invention relates to the field of concrete preparation. More particularly, the invention relates to concrete and a preparation method thereof, and the concrete is characterized by comprising the following components in parts by mass: 60-85 parts of water, 120-170 parts of cement, 380-480 parts of a fine aggregate, 326-462 parts of ceramsite, 45-60 parts of fly ash, 5-9 parts of a water reducing agent and 10-18 parts of a fiber mixture. The concrete has the beneficial effects that the durability of the concrete is enhanced, and meanwhile, the environmental protection requirement is favorably met.

Owner:广东承沐建设工程有限公司

High-performance roadway wall back filling layer material taking pretreated phosphogypsum as aggregate

InactiveCN114180922AThe preparation operation process is simpleLow costAggregate (composite)Land resources

The invention belongs to the technical field of roadway wall back filling layers and solid waste recycling, and discloses a high-performance roadway wall back filling layer material with pretreated phosphogypsum as aggregate. According to the ardealite backfill material, ardealite which is pretreated after being dried for 8 hours at the temperature of 130 DEG C is used as aggregate, slag and carbide slag are added, the mixture is stirred with tap water, and no other additive is added. The ardealite, the slag and the carbide slag pretreated by the aggregate used by the wall back filling layer material respectively account for 65-75%, 20-25% and 5-10% of the total solid mass. The ardealite wall back filling layer manufactured according to the mixing ratio can meet the compressive strength requirement, the fluidity requirement and the water permeability requirement of the wall back filling layer in a roadway composite support system, and has the advantages of being low in cost and easy and convenient to manufacture. Meanwhile, the problem that a large amount of industrial solid wastes such as ardealite and the like are accumulated is solved, land resource pressure is released, contribution is made to environmental protection, and certain practical significance is achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

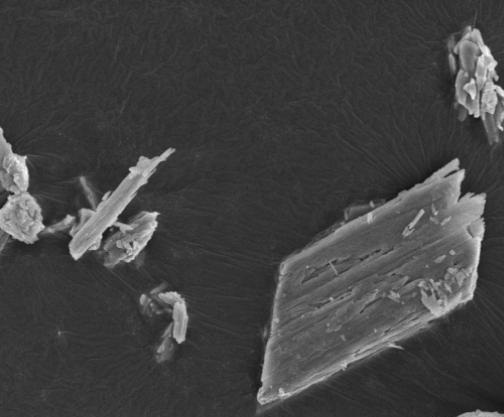

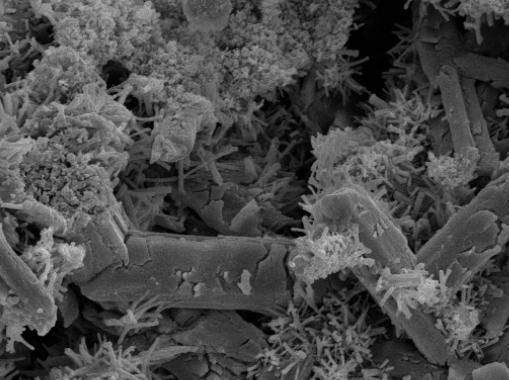

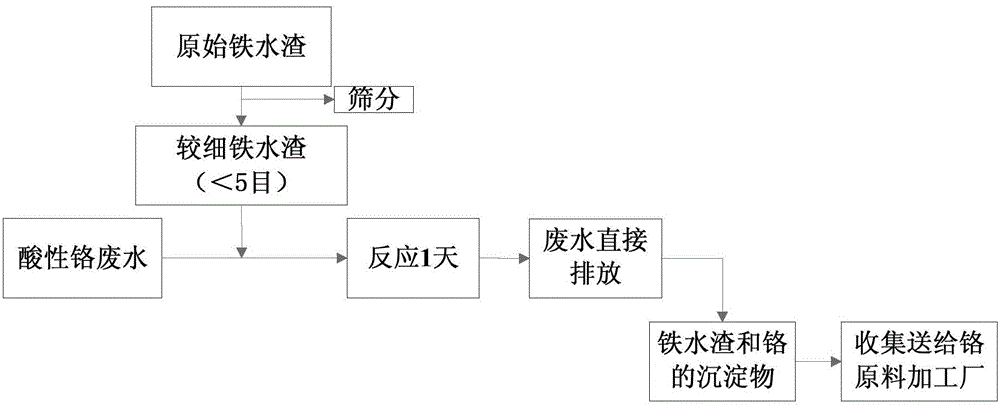

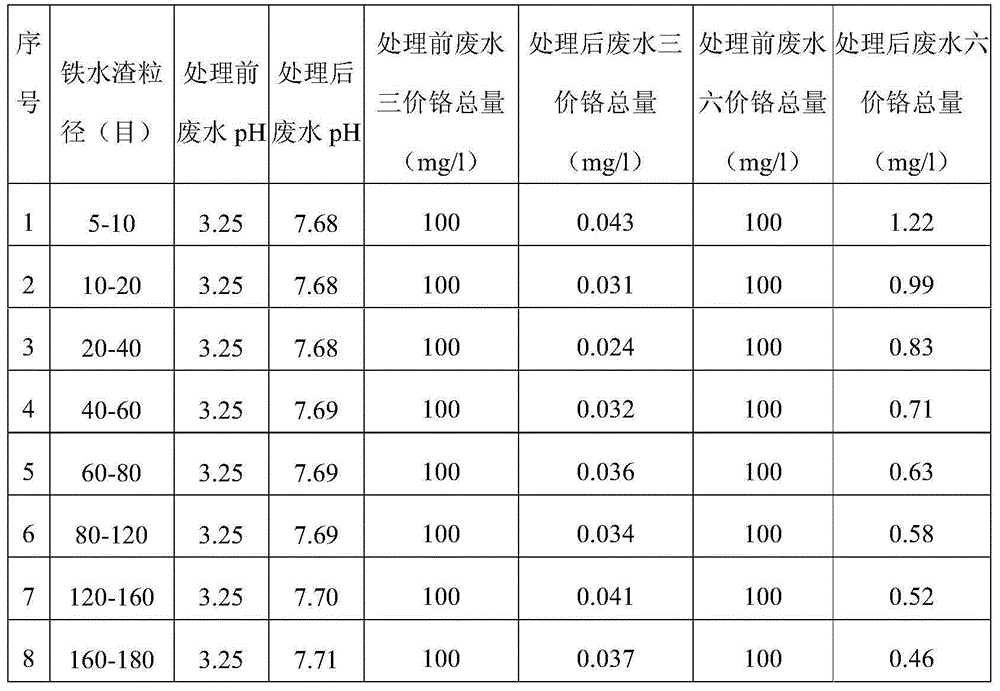

Method for treating acid chromium-contained polluted waste water with molten iron residues as raw material

InactiveCN105060439ALow costHigh densityWater contaminantsWater/sewage treatment by flocculation/precipitationChromiumWater treatment

The invention relates to the field of heavy metal pollution treatment, in particular to new application of molten iron residues in the field of treating polluted waste water. The method for treating acid chromium-contained polluted waste water with molten iron residues as raw material includes the following steps that 1, molten iron residues are added to acid chromium-contained polluted waste water; 2, after the molten iron residues and the acid chromium-contained polluted waste water are mixed to react with each other for 12 hours to 36 hours, the treated waste water is discharged directly, the molten iron residues precipitated at the bottom and Cr (OH) 3 sediment are collected and recycled. The method for treating acid chromium-contained polluted waste water with molten iron residues as raw material provides a new way for acid chromium-contained polluted waste water treatment and comprehensive utilization of the molten iron residues.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

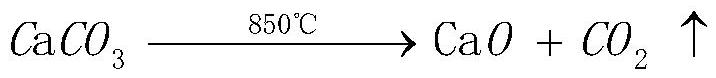

Oil field steam filling boiler of circulation fluidized bed using water coal slurry as fuel

InactiveCN1276215CImprove use valueGellingFluidized bed combustionCombustion using lump and liquid fuelWear resistantEngineering

The oil well gas injecting boiler has screw pump in pressure of 0.2-0.4 MPa to supply fuel from the upper part of the boiler, single steam drum in naturally circulating mode to obtain high pressure steam of 17.5-21 MPa; quartzite and limestone powder as fuidizing medium for low multiplying factor circulation; and power amount of limestone powder for clean burning at temperature of 850-950 deg.c. The boiler of the present invention has water cooling furnace wall, coated heat resistant and corrosion resistant refractory material and sprayed heat resistant and wear resistant Ni-Cr alloy, pipe type backwards bent boiler top, coal economizer of ribbed spiral pipes, cyclonic separator with wear resistant material, water cooling wall with inner thread pipe, high temp alloy steel material in high temperature and high pressure sections, welded support frame structure, flexible 3D expanding section in important joint part, and hydrostats.

Owner:SHENYANG DAVID ENVIRONMENT PROTECTION & ENERGY SAVING EQUIP LTD

Feed capable of improving immunity of piglets and preparation method thereof

InactiveCN109007375AImprove immunitySoft tasteFood processingAnimal feeding stuffAnimal scienceAdditive ingredient

The invention discloses feed capable of improving the immunity of piglets and a preparation method thereof, which andbelongs to the field of feed processing. Energy feed and protein feed are used as main base materials of the feed; and by adding various auxiliary materials, on the premise of not damaging the nutritional ingredients of the feed, the performance of improving the immunity of the feedfor improving the immunity can be improved, the use of antibiotics can also be avoided, and the healthy processing of the meat can be facilitated; and the prepared feed is loose and soft in taste, the energy feed and the protein feed can provide a necessary nutritional base for the growth of organisms, and the cooperation of the additives and the main materials facilitates the growth of the piglets and improves the body immunity of the piglets, and the disease rate can be reduced.

Owner:ANHUI QIANGJIAZHUANG ECOLOGICAL AGRI

A kind of iron slag concrete and preparation method

The invention provides jarosite slag concrete and a preparation method, and relates to the technical field of building materials. The method comprises the steps that jarosite slag containing oxides such as CaO, SiO2 Al2O3 is similar to concrete in chemical component so that the jarosite slag can be used for partially replacing cement in the concrete, the jarosite slag, ordinary Portland cement, fine aggregate, coarse aggregate and water are used for preparing different types of concrete, 11-15 parts by weight of water, 16-31 parts by weight of cement, 4-13 parts by weight of jarosite slag, 104-129 pats by weight of coarse aggregate and 60-74 parts by weight of fine aggregate are mixed, and 0-2.5 parts by weight of water is added; generally, a zinc smelting plant can pile up a large amountof jarosite slag, the piling up processing difficulty is great, and meanwhile the environment is polluted. The jarosite slag can be used for preparing concrete products with different strength grades,and engineering application is wide.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of multifunctional water purification agent and preparation method thereof

ActiveCN103864190BGellingMalleableWater/sewage treatment by flocculation/precipitationPorosityChemical oxygen demand

The invention relates to a multifunctional water purifier and a preparation method thereof. The purifier comprises a metal salt water solution and a gel aqueous solution, wherein the volume ratio of the metal salt water solution to the gel aqueous solution is (1-3):1; the metal salt water solution is any combination of more than two of a ferric salt water solution, an aluminum salt water solution, a magnesium salt water solution and a calcium salt water solution; the gel aqueous solution is one of a gelatin water solution, an agar water solution and an xanthan gum water solution. The gelatinization properties of the metal salt and the gel are combined, so that the multifunctional water purifier not only has an efficient removal effect on pollutants such as chemical oxygen demand (COD), total protein (TP), NH3<->N and the like caused by the metal salt, but also has the advantages of gelling property, plasticity, loose porosity, biodegradability and the like of the gelling agent, simultaneously has the characteristics of being wide in application range, convenient to transport, easy to separate, high in utilization rate, free of harm to environment and the like, and can be repeatedly utilized.

Owner:浙江一清环保工程有限公司

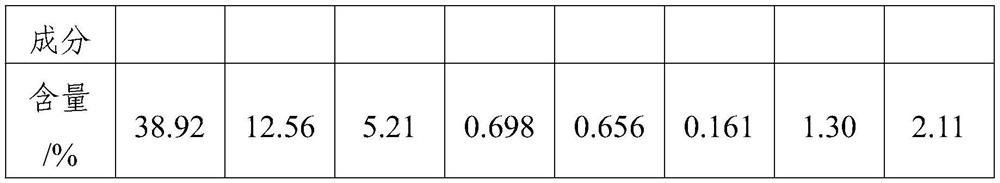

Cold-cut vegetarian sausage and preparation method thereof

ActiveCN111202226AThe cut surface is red and whiteExcellent texture indexFood ingredient as gelling agentFood ingredient as mouthfeel improving agentBiotechnologyCarrageenan

The present invention discloses a cold-cut vegetarian sausage and a preparation method thereof. The cold-cut vegetarian sausage is prepared from konjac powder, carrageenan, potassium chloride, recombinant fat, edible essences, hydroxypropyl starch and ice water in a specific ratio, wherein the recombinant fat is prepared by mixing sodium alginate, calcium sulfate, salad oil and water, and if a relatively heavy taste requirement is needed, a small amount of pork bone soup-stock can also be added to the recombinant fat. Compared with protein-like vegetarian sausage products, the cold-cut vegetarian sausage is mainly based on functional polysaccharides and more similar to Western-style hams and cold-cut sausages in product shapes, mouthfeel and flavor. The cold-cut vegetarian sausage has a distinct red-white cut surface, is crisp in mouthfeel, etc. similar to meat products, has excellent texture indexes, and has very good market promotion value.

Owner:临沂金锣文瑞食品有限公司

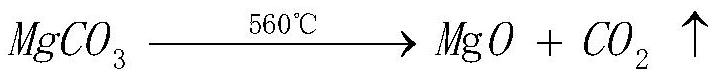

A kind of magnesia expansion agent prepared by using high-calcium magnesite tailings and its preparation method

ActiveCN110066128BRetains its own expansive propertiesImprove mechanical propertiesAluminium hydroxideEconomic benefits

The invention discloses a magnesia expansion agent and a method prepared by using high-calcium magnesite tailings. The magnesia expansion agent of the present invention uses high-calcium magnesite tailings as the main raw material, and uses aluminum hydroxide as the adjusting material. It was prepared by calcination at 1050°C. The present invention utilizes the Al produced by the decomposition of aluminum hydroxide 2 O 3 Absorb the f-CaO produced by the decomposition of high-calcium magnesite tailings to form the cementitious substances monocalcium aluminate and dodecalumina heptaaluminate, which significantly reduces the production of magnesite expansion agent from high-calcium magnesite tailings. The content of f-CaO solves the social problem of high-calcium magnesite tailings causing pollution to the ecological environment, expands the direction for the high value-added application of high-calcium magnesite tailings, and reduces the use of magnesite expansion agents. The production cost provides market competitiveness for the promotion and application of magnesium expansion agent in water conservancy and hydropower projects, and has significant social and economic benefits.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

A treatment process of nickel slag in the process of nickel slag concrete processing

The invention discloses a nickel slag processing technology in a nickel slag concrete manufacturing process. The processing technology specifically comprises the steps of powder grinding and refining treatment, hydration activity treatment and durability treatment. The processing technology has the advantages that abrasion of iron to a roller press can be effectively reduced via a novel high efficient powder grinding and demagnetizing mechanism, the service life of the roller press can be prolonged, and iron content in the nickel slag can be effectively removed via two times of deironing; due to the mode of introducing nickel stream into a high-temperature vacuum furnace, and sieving nickel powder, particle diameters of the nickel powder can be effectively controlled, the condition that the nickel slag has uniform powder particle size is ensured, and thus quality of subsequently manufactured nickel slag concrete can be further improved; formation of hydration products under a hydrothermal condition is facilitated by adjusting a CaO / SiO2 ratio, the composition of the nickel slag and kaoline and the hydrothermal condition and by using a seed crystal technology, and thus hydrate with gelling property can be acquired; minerals such as tobermorite and Mg(OH)2 are formed by using the high temperature and high pressure hydrothermal technology, and thus MgO content is effectively reduced, and durability of the nickel slag concrete is improved.

Owner:江苏中鼎建材集团有限公司

Environment-friendly high-performance waterproof flame-retardant plastering mortar and preparation method thereof

Owner:WUHAN UNIV OF TECH

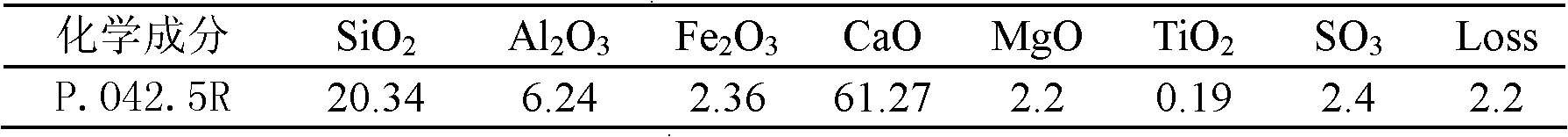

Electrolytic manganese residue harmless processing composition

InactiveCN109627071AWill not polluteGellingMagnesium fertilisersSolid waste disposalElectrolysisPhosphate

The invention discloses an electrolytic manganese residue harmless processing composition. The composition comprises, by weight, 0.05-0.5 part of phosphate, 5-20 parts of a mixture of magnesium hydrate and magnesium oxide and 0.05-0.3 part of carboxylic acid when 100 parts of electrolytic manganese residues are processed. When the electrolytic manganese residues are processed, the processing costis low, energy consumption is low, the processing steps are simple, operation is easy, and the pollution of stacking of the electrolytic manganese residues to the surrounding environment is avoided.

Owner:吾道环保科技有限公司

Modification method of soybean protein concentrate

InactiveCN1277486CNSI improvedIncrease nutritionProtein composition from vegetable seedsSolubilityWater insoluble

Owner:夏中军

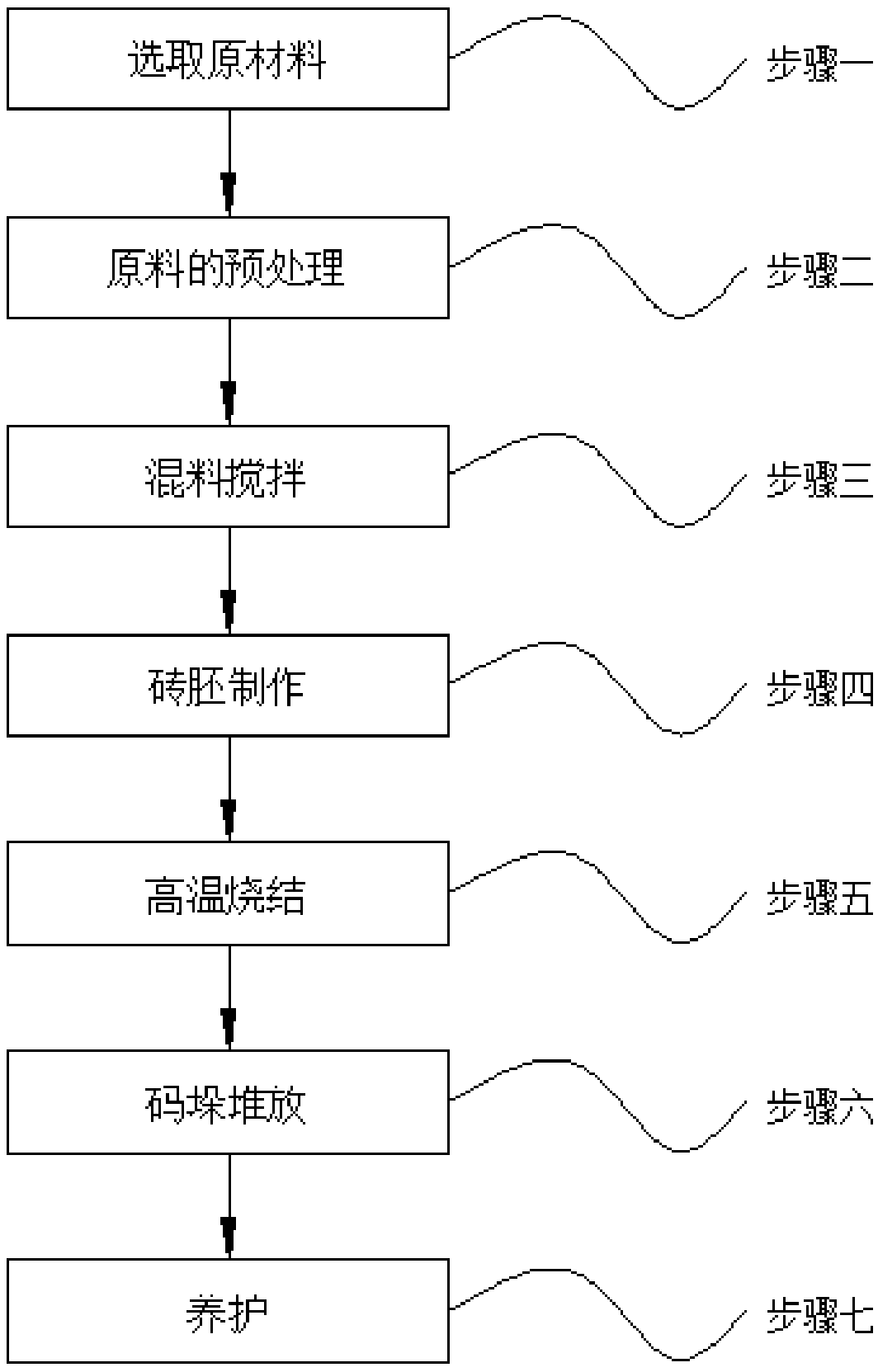

Technological method for producing water permeable bricks through dry slag

InactiveCN109400119AGood water permeabilityIncreased strength and bearing capacityCeramic materials productionCeramicwareAdhesiveEmbryo

The invention discloses a technological method for producing water permeable bricks through dry slag. The technological method includes the following steps that firstly, raw materials are selected; secondly, the raw materials are pretreated; thirdly, mixing and stirring are conducted; fourthly, brick embryos are produced; fifthly, high sintering is conducted; sixthly, stacking and piling are conducted; and seventhly, curing is conducted, and wherein in the step one, the dry slag, adhesives, quartz, fine powder, white cement, permeable fibers, silica sand and mineral color powder are selected as the raw materials. According to the technological method for producing the water permeable bricks through the dry slag, the water permeable bricks are produced by the raw materials of the selected dry slag, the adhesives, the quartz, the fine powder, the white cement, the permeable fibers, the silica sand and the mineral color powder, the water permeability is good, the strength and bearing capacity are high, the water permeable bricks with different colors can be made according to different mineral color powder, and the color is rich; and in the production process, the steps are simple, thedry slag is effectively reused, environmental pollution is lowered, the production cost is effectively lowered, and the production efficiency is improved.

Owner:贵州瑞泰实业有限公司

A kind of preparation method of iron slag autoclaved brick

The invention discloses a preparation method of a jarosite slag steam-pressing brick, and relates to the technical field of building materials. The jarosite slag steam-pressing brick is prepared from,by weight, 5.6-27 parts of water, 16-45 parts of cement, 4-13 parts of jarosite slag, 104-129 parts of coarse aggregate and 60-74 parts of fine aggregate, the water cement ratio is 0.35-0.60, and 0.1-0.5 part by weight of additives are adopted. The jarosite slag steam-pressing brick prepared through the method has compressive strength, the requirements of different concrete strength grades can bemet, the problems of resource waste and environmental pollution generated by jarosite slag piling up and landfill are solved, energy conservation and environment protection are achieved, sustainabledevelopment of the resource environment is facilitated, the jarosite slag is used for partially replacing cement, the dosage of the cement is reduced, the engineering cost is lowered, the manufacturing cost of the steam-pressing brick is lowered, and the method has a wide engineering application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A modified glass tailings cement-based auxiliary cementitious material and its preparation method

ActiveCN104129935BHigh bonding strengthSmall shrinkage deformationCement productionCalcium in biologySlag

The invention discloses a modified glass tailings cement based auxiliary gelling material and a preparation method thereof. The material comprises glass tailings and modified auxiliary in the weight ratio of 70-100:0-30 materials; the modified auxiliary is a calcareous material or calcium magnesium material or a mixture of the two in any mass ratio. All the materials are mixed and treated by one method selected from mechanical grinding, hydrothermal treatment, low temperature calcination and hydrothermal-calcination. The invention conducts surface modification on the glass tailings to improve the surface gelling property of the glass tailings, reduce the shrinkage deformation of the cement based material and improve the early mechanical properties. The invention makes full use of industrial wastes of glass tailings, calcium carbide slag and magnesite tailings to develop a novel cement based auxiliary gelling material, which can reduce the dosage of cement clinker, prolong the service life of cement based material, indirectly reduce the energy consumption for cement production, and reduce carbon dioxide emission. The invention has important meaning to energy saving, emission reduction and the sustainable development of cement concrete industry.

Owner:WEST ANHUI UNIV +1

Waterproof isolation plate and preparation method thereof

InactiveCN112110708AStrong impact resistanceImprove bending resistanceSolid waste managementCelluloseShrinkage rate

The invention provides a waterproof isolation plate. The waterproof isolation plate uses industrial solid waste alkaline residues as a main raw material and achieves the purposes of excellent waterproof performance and high strength through the cooperation of the alkaline residues, an aggregate forming agent, lime and cellulose. The aggregate forming agent provided by the invention has a gelling property, and in the process of hardening, the strength of the alkaline residues is excited, and the strength of the obtained isolation plate is improved; the lime can improve the tensile strength of the alkaline residues and the aggregate forming agent, and can also react with a part of raw aluminum oxide or silicon oxide in the aggregate forming agent to generate substances with hydraulic performance so as to realize cementation, so the strength of the isolation plate is further improved; and the cellulose can improve the toughness and strength of the isolation plate. According to the waterproof isolation plate provided by the invention, through the interaction of all the components, the obtained waterproof isolation plate has good impact resistance, bending resistance, small drying shrinkage rate and good waterproof performance.

Owner:唐山中陶纪元工程设计有限公司

Slope protection material and preparation method thereof

ActiveCN103833298BEfficient use ofReduce consumptionSolid waste managementStrength of materialsMechanical property

The invention belongs to the building material field, and particularly relates to a slope protection material and a preparation method thereof. The slope protection material comprises a cementing material, aggregates, modified aggregates, and water; the cementing material is prepared from cement, municipal solid wastes with a particle size of 1-3 mm, an exciting agent, and industrial waste residues; the aggregates are prepared from municipal solid wastes with a particle size of 1-3 mm; the modified aggregates are prepared from municipal solid wastes with a particle size of 4-10 mm, a surface reinforcing agent and water. The preparation method of the invention can make efficient use of municipal solid wastes, reduce resource and energy consumption caused by building material production, and is simple in production and construction process; the prepared slope protection material is high in mechanical properties; land occupation and environment pollution caused by stacking of municipal solid wastes are reduced; and the social, economic and environment benefits are remarkable.

Owner:ZIBO HUANYI RESOURCE INTEGRATION UTILIZATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com