A treatment process of nickel slag in the process of nickel slag concrete processing

A processing and treatment technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of poor abrasiveness of nickel slag, low performance of concrete application, and durability of concrete. Achieve the effect of improving ball milling efficiency, prolonging service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A process for treating nickel slag in the nickel slag concrete processing process, the specific steps are:

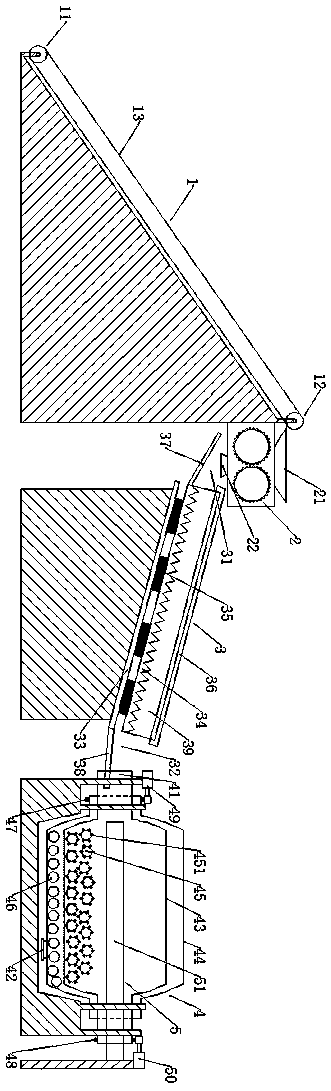

[0031] 1) Grinding refinement treatment: first put nickel slag into a new type of high-efficiency grinding and demagnetization mechanism, perform pre-grinding, first iron removal, final grinding and second iron removal to obtain nickel slag powder; Then put the nickel slag powder into the high-temperature vacuum furnace, heat it to 200°C, adjust the vacuum degree to 0.05Pa, and keep it for 5 minutes; then pass nickel vapor into the high-temperature vacuum furnace, control the pressure at 80Kpa, and stir for 10 minutes; then dry the nickel powder and sieving to obtain nickel slag powder with consistent particle size;

[0032] 2) Hydration activity treatment: first add CaO and SiO to the nickel slag powder obtained in step 1) 2 and kaolin, stirred for 15 minutes until fully mixed; then the mixture was placed in a hydrothermal kettle, and seed crystals were added, ...

Embodiment 2

[0037] A process for treating nickel slag in the nickel slag concrete processing process, the specific steps are:

[0038] 1) Grinding refinement treatment: first put nickel slag into a new type of high-efficiency grinding and demagnetization mechanism, perform pre-grinding, first iron removal, final grinding and second iron removal to obtain nickel slag powder; Then put the nickel slag powder into the high-temperature vacuum furnace, heat it to 300°C, adjust the vacuum degree to 0.04Pa, and keep it for 8 minutes; then pass nickel vapor into the high-temperature vacuum furnace, control the pressure at 20KPa, and stir for 20 minutes; then dry the nickel powder and sieving to obtain nickel slag powder with consistent particle size;

[0039] 2) Hydration activity treatment: first add CaO and SiO to the nickel slag powder obtained in step 1) 2 and kaolin, stirred for 10 minutes until fully mixed; then the mixture was placed in a hydrothermal kettle, and seed crystals were added, ...

Embodiment 3

[0044] A process for treating nickel slag in the nickel slag concrete processing process, the specific steps are:

[0045] 1) Grinding refinement treatment: first put nickel slag into a new type of high-efficiency grinding and demagnetization mechanism, perform pre-grinding, first iron removal, final grinding and second iron removal to obtain nickel slag powder; Then put the nickel slag powder into the high-temperature vacuum furnace, heat it to 250°C, adjust the vacuum degree to 0.045Pa, and keep it for 7 minutes; then pass nickel vapor into the high-temperature vacuum furnace, control the pressure at 50KPa, and stir for 15 minutes; then dry the nickel powder and sieving to obtain nickel slag powder with consistent particle size;

[0046] 2) Hydration activity treatment: first add CaO and SiO to the nickel slag powder obtained in step 1) 2 and kaolin, stirred for 12 minutes until fully mixed; then the mixture was placed in a hydrothermal kettle, and seed crystals were added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com