A kind of preparation method of iron slag autoclaved brick

A technology of jarosite slag and autoclaved bricks, which is applied in the field of preparation of jarosite slag autoclaved bricks, can solve the problems of difficulty in stacking and processing, polluting the environment, and large amount of slag, and achieves simple and feasible operation, reduced cement consumption, and reduced The effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

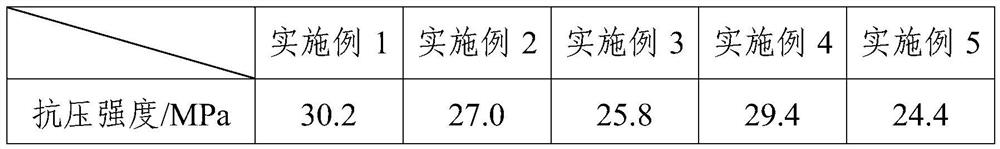

Examples

Embodiment 1

[0022] A jarosite slag autoclaved brick, which is composed of the following raw materials in parts by weight: 13.5 parts of water, 30 parts of cement, 8 parts of jarosite slag, 117 parts of coarse aggregate, 67 parts of fine aggregate, 0.1 part of calcium chloride, Magnesium chloride is 0.2 parts, and the water-cement ratio is 0.45.

[0023] Among them, the cement adopts P.O42.5 ordinary Portland cement.

[0024] Among them, the coarse aggregate is continuously graded crushed stone with a particle size of 11.5 mm and a moisture content of 0.5%.

[0025] Among them, the fine aggregate has a fineness modulus of 2.77 and a moisture content of 2.6%, which belongs to the ordinary sand in the middle sand II zone.

[0026] The preparation method of the above-mentioned ferrite slag autoclaved brick comprises the following steps:

[0027] (1) Take each raw material according to the component distribution ratio, put the coarse aggregate, fine aggregate, alumina slag, cement and admixt...

Embodiment 2

[0030] A jarosite slag autoclaved brick, which is composed of the following raw materials in parts by weight: 27 parts of water, 45 parts of cement, 6 parts of jarosite slag, 129 parts of coarse aggregate, 74 parts of fine aggregate, 0.1 part of calcium chloride, Sodium chloride is 0.1 part, and the water-cement ratio is 0.6.

[0031] Among them, the cement adopts P.O42.5 ordinary Portland cement.

[0032] Among them, the coarse aggregate is continuously graded crushed stone with a particle size of 5mm and a moisture content of 0.5%.

[0033] Among them, the fine aggregate has a fineness modulus of 2.77 and a moisture content of 2.6%, which belongs to the ordinary sand in the middle sand II zone.

[0034] The preparation method of the above-mentioned ferrite slag autoclaved brick comprises the following steps:

[0035] (1) Take each raw material according to the component distribution ratio, put the coarse aggregate, fine aggregate, alumina slag, cement and admixture into th...

Embodiment 3

[0038] A jarosite slag autoclaved brick, which is composed of the following raw materials in parts by weight: 10 parts of water, 25 parts of cement, 4 parts of jarosite slag, 104 parts of coarse aggregate, 60 parts of fine aggregate, 0.2 part of sodium chloride, Magnesium chloride is 0.1 part, and the water-cement ratio is 0.4.

[0039] Among them, the cement adopts P.O42.5 ordinary Portland cement.

[0040] Among them, the coarse aggregate is continuously graded crushed stone with a particle size of 19.5 mm and a moisture content of 0.5%.

[0041] Among them, the fine aggregate has a fineness modulus of 2.77 parts and a moisture content of 2.6%, which belongs to the ordinary sand in the middle sand zone II.

[0042] The preparation method of the above-mentioned ferrite slag autoclaved brick comprises the following steps:

[0043] (1) Take each raw material according to the component distribution ratio, put the coarse aggregate, fine aggregate, alumina slag, cement and admix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com