Technological method for producing water permeable bricks through dry slag

A process method and heavy slag technology are applied in the field of using heavy slag to produce permeable bricks, which can solve the problems of poor strength and pressure bearing capacity, ineffective utilization, and low production efficiency, and achieve high strength and pressure bearing capacity. The effect of enriching and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

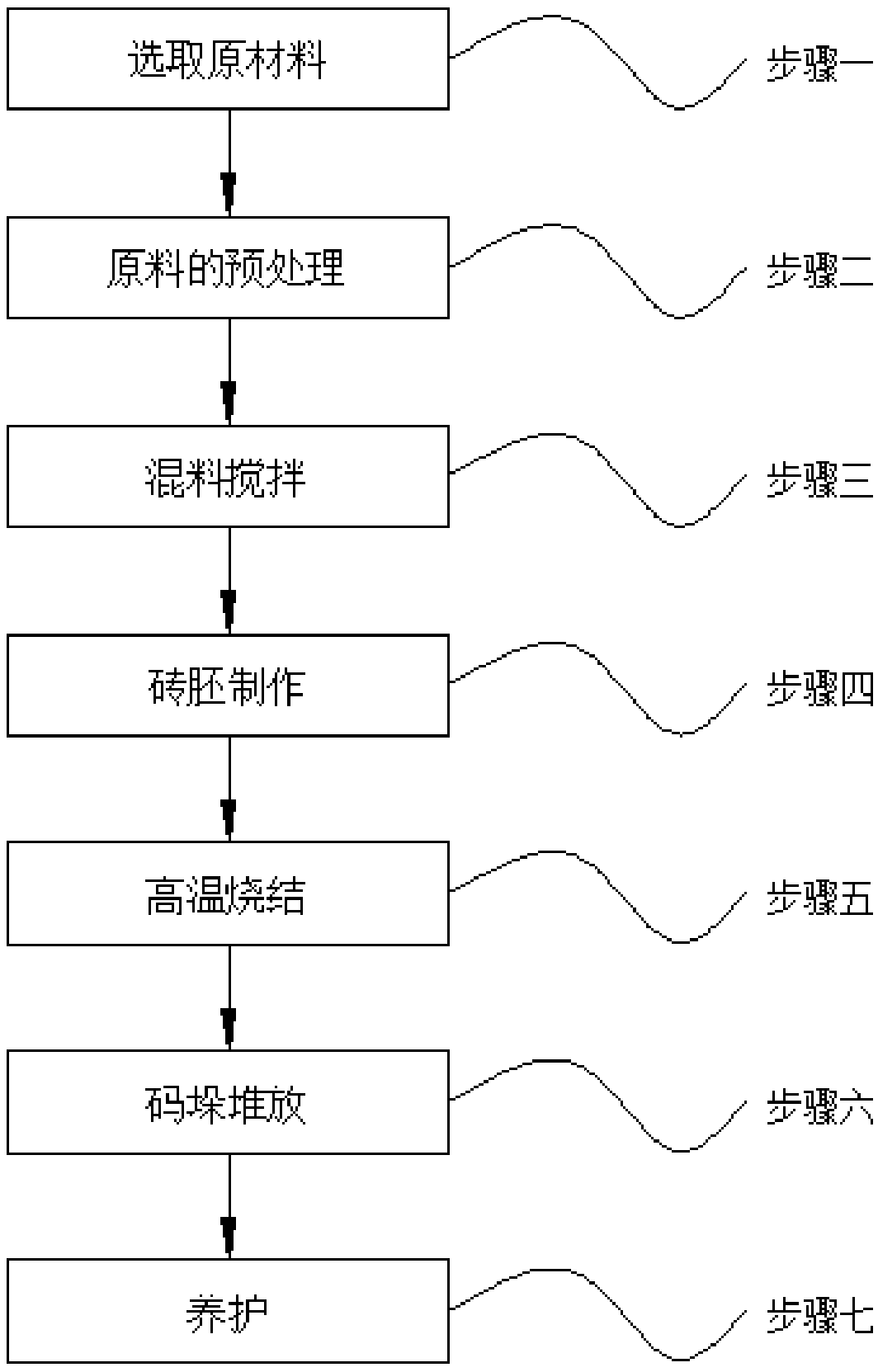

[0030] A process for producing permeable bricks using heavy slag, comprising the following steps: Step 1, selecting raw materials; Step 2, pretreatment of raw materials; Step 3, mixing and stirring; Step 4, making brick embryos; Step 5, high-temperature sintering; Step six, stacking; step seven, maintenance;

[0031] Wherein in the above-mentioned step 1, heavy slag, adhesive, quartz, fine powder, white cement, water-permeable fiber, silica sand and mineral toner are selected as raw materials, according to 30% of heavy slag, 6% of adhesive, 19% of quartz, and 13% of fine powder. %, 12% white cement, 8% permeable fiber, 8% silica sand and 4% mineral toner;

[0032] Wherein in the above-mentioned step 2, the heavy slag, quartz and silica sand are separately placed in a calciner for high-temperature calcination. After the calcination is completed, the heavy slag, quartz and silica sand are placed in a pulverizer for initial crushing. After the crushing is completed, the The pulv...

Embodiment 2

[0040] A process for producing permeable bricks using heavy slag, comprising the following steps: Step 1, selecting raw materials; Step 2, pretreatment of raw materials; Step 3, mixing and stirring; Step 4, making brick embryos; Step 5, high-temperature sintering; Step six, stacking; step seven, maintenance;

[0041] Wherein in the above-mentioned step one, select heavy slag, adhesive, quartz, fine powder, white cement, water-permeable fiber, silica sand and mineral toner as raw materials, according to heavy slag 35%, adhesive 5%, quartz 17%, fine powder 11% %, 10% white cement, 7% permeable fiber, 10% silica sand and 5% mineral toner;

[0042]Wherein in the above-mentioned step 2, the heavy slag, quartz and silica sand are separately placed in a calciner for high-temperature calcination. After the calcination is completed, the heavy slag, quartz and silica sand are placed in a pulverizer for initial crushing. After the crushing is completed, the The pulverized matter obtaine...

Embodiment 3

[0050] A process for producing permeable bricks using heavy slag, comprising the following steps: Step 1, selecting raw materials; Step 2, pretreatment of raw materials; Step 3, mixing and stirring; Step 4, making brick embryos; Step 5, high-temperature sintering; Step six, stacking; step seven, maintenance;

[0051] Wherein in the above-mentioned step 1, heavy slag, adhesive, quartz, fine powder, white cement, water-permeable fiber, silica sand and mineral toner are selected as raw materials, according to 40% of heavy slag, 5% of adhesive, 15% of quartz, and 9% of fine powder. %, 8% white cement, 5% permeable fiber, 11% silica sand and 7% mineral toner;

[0052] Wherein in the above-mentioned step 2, the heavy slag, quartz and silica sand are separately placed in a calciner for high-temperature calcination. After the calcination is completed, the heavy slag, quartz and silica sand are placed in a pulverizer for initial crushing. After the crushing is completed, the The pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com