Pervious concrete and preparation method thereof

A permeable concrete and concrete technology, applied in the field of building materials, can solve the problems of structural damage, affecting strength, and poor freeze-thaw resistance of permeable concrete, and achieve the effects of increasing concentration, avoiding cracking, and improving the ability to prevent early freezing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

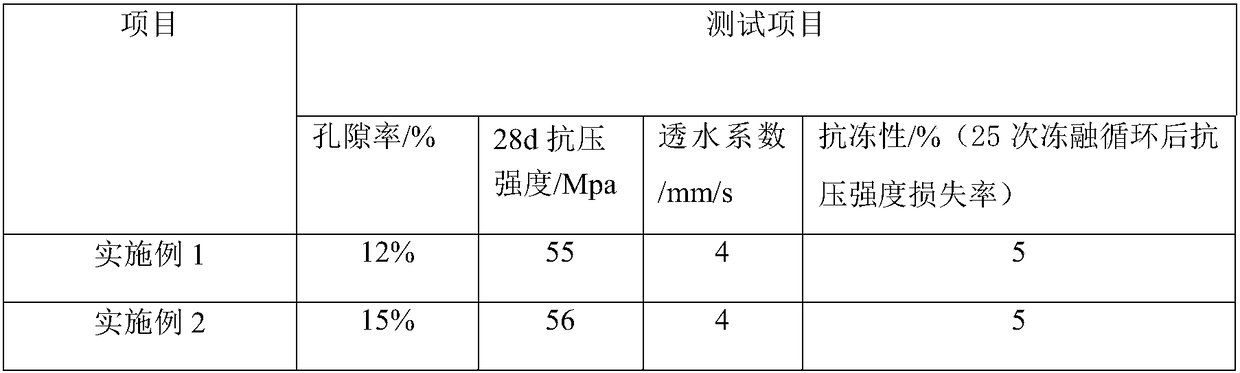

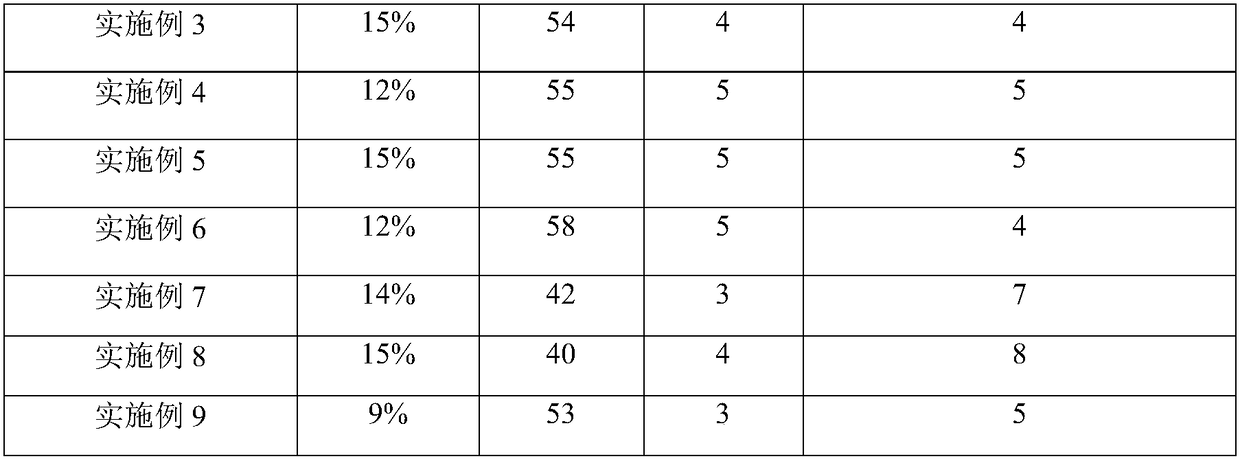

Examples

Embodiment 1

[0027] A permeable concrete, including the following raw materials configured by weight: Ordinary Portland cement 200kg / m 3 , coarse aggregate 1250kg / m 3 , mineral admixture 150kg / m 3 , EVA emulsion 10kg / m 3 , enhancer 5kg / m 3 And composite antifreeze, the weight of the composite antifreeze is 1% of the total weight of concrete; the water-cement ratio of the concrete is 0.2;

[0028] The composite antifreeze agent comprises triethanolamine, sulfamate and lignosodium, and the mass ratio of the triethanolamine, sulfamate and lignosodium is 5:1:1.

[0029] In this example, the ordinary Portland cement is P·O 52.5, and its strength is higher; the coarse aggregate is selected from crushed stones with a particle size within the range of 9 to 12 mm, and its mud content is ≤0.5%, and the needle shape is less than 10%, the mineral admixture is sulfur-fixed ash.

Embodiment 2

[0031] A permeable concrete, including the following raw materials configured by weight: Ordinary Portland cement 300kg / m 3 , coarse aggregate 1350kg / m 3 , mineral admixture 280kg / m 3 , EVA emulsion 15kg / m 3 , enhancer 5 ~ 10kg / m 3 And composite antifreeze, the weight of the composite antifreeze is 2.5% of the total weight of concrete; the water-cement ratio of the concrete is 0.31;

[0032] The compound antifreeze agent comprises triethanolamine, sulfamate and lignosodium, and the mass ratio of the triethanolamine, sulfamate and lignosodium is 4:1:1.

[0033] In this example, the ordinary Portland cement is P·O 52.5, and its strength is higher; the particle size of the coarse aggregate is 9-12mm, the mud content is ≤0.5%, and the crushed stones of needle-shaped <10%, mineral The admixture is at least one kind of slag.

Embodiment 3

[0035] A permeable concrete, including the following raw materials configured by weight: Ordinary Portland cement 220kg / m 3 , coarse aggregate 1300kg / m 3 , mineral admixture 210kg / m 3 , EVA emulsion 12kg / m 3 , enhancer 8kg / m 3 And composite antifreeze, the weight of the composite antifreeze is 2% of the total weight of concrete; the water-cement ratio of the concrete is 0.25;

[0036] The composite antifreeze agent includes triethanolamine, sulfamic acid salt and lignosodium, and the mass ratio of the triethanolamine, sulfamic acid salt and lignosodium is 6:1:1.

[0037] In this example, the ordinary Portland cement is P·O 52.5, and its strength is higher; the particle size of the coarse aggregate is 9-12mm, the mud content is ≤0.5%, and the crushed stones of needle-shaped <10%, mineral Admixtures are slag and sulfur-fixed ash.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com