Concrete and preparation method thereof

A technology for concrete and mixture, applied in the field of concrete and its preparation, can solve the problems of low tensile strength cement concrete structure durability and the like, and achieve the effects of improving structural strength, durability, compactness, and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

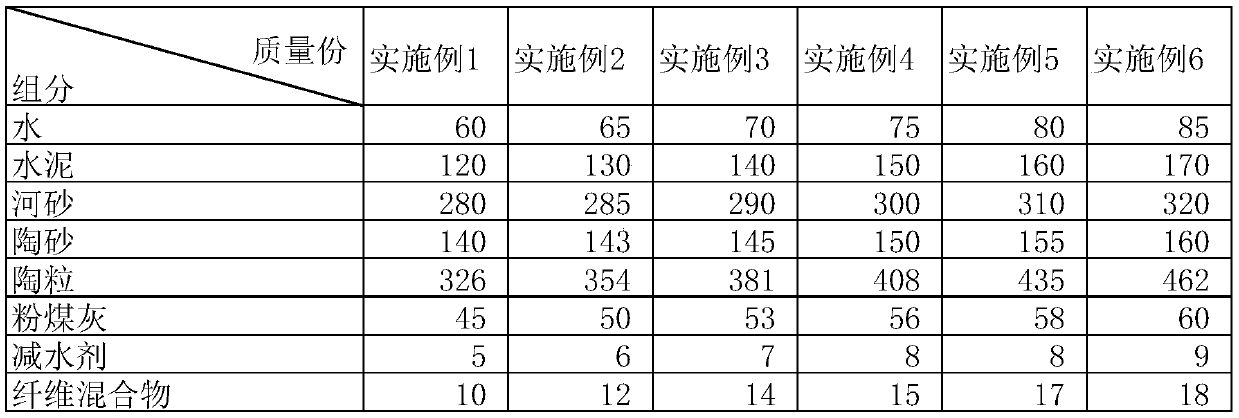

[0063] A concrete, its components and parts by mass are shown in Table 1.

[0064] Fine aggregate is a mixture of river sand and pottery sand in a mass ratio of 2:1.

[0065] Wherein, the water reducer is sodium lignin sulfonate.

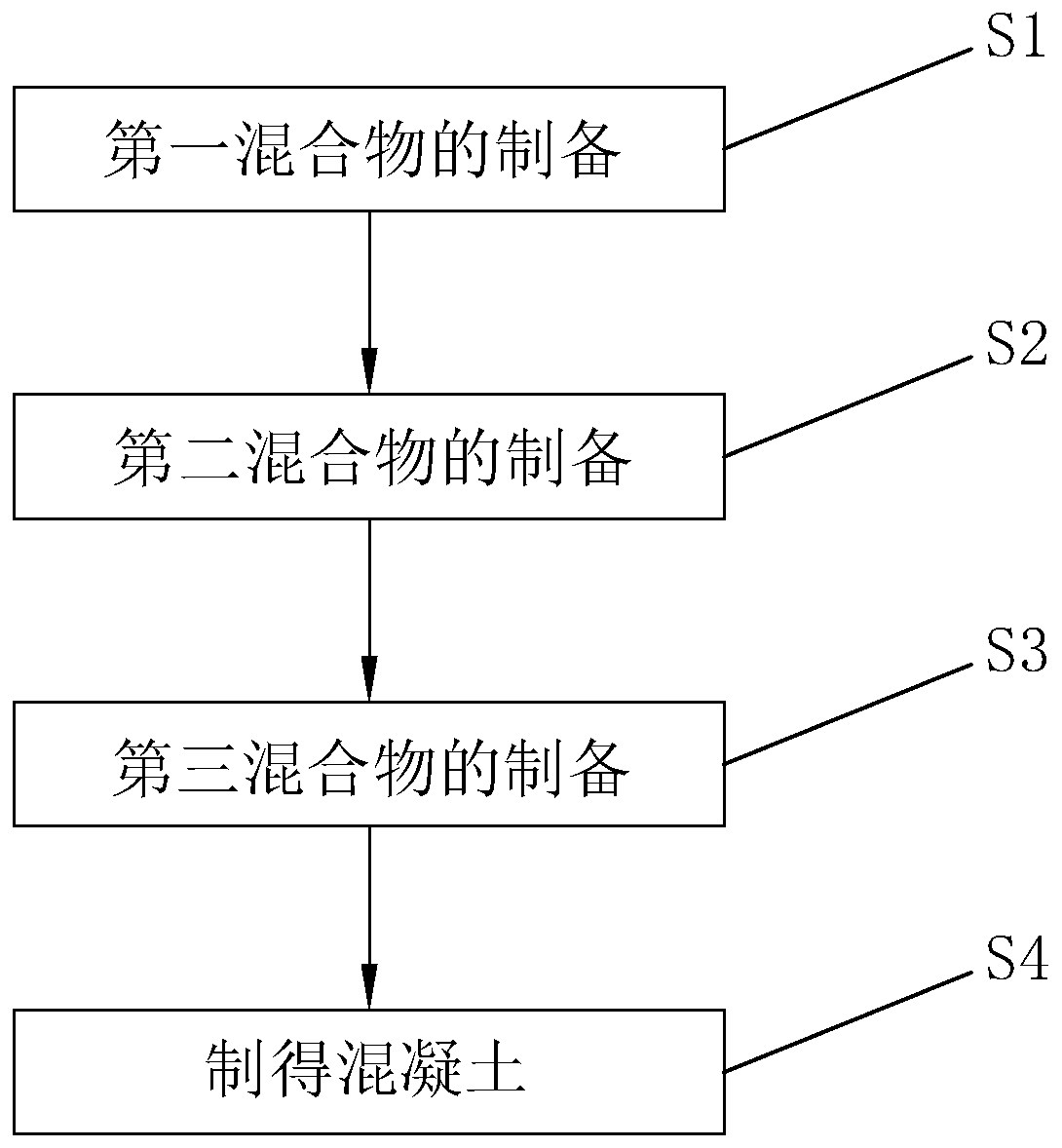

[0066] A method for preparing concrete, comprising the steps of:

[0067] S1. Preparation of the first mixture: In a cement mixer, under normal temperature, add corresponding parts by mass of water and cement, and stir at a speed of 200 r / min to prepare the first mixture.

[0068] S2. Preparation of the second mixture: add corresponding parts by mass of water reducer and fiber mixture to the first mixture while stirring, and obtain the second mixture after uniform stirring.

[0069] S3. Preparation of the third mixture: In a sandstone mixer, under normal temperature, add corresponding mass parts of fine aggregate, ceramsite and fly ash, stir at a speed of 300r / min, and obtain the third mixture after stirring evenly .

[0070] S4. Preparing concret...

Embodiment 2

[0072] A concrete, the difference from Example 1 is that its components and parts by mass are shown in Table 1.

[0073] Wherein, the fiber mixture is corn stalk fiber, and the preparation method of corn stalk fiber is as follows:

[0074] (1) Mechanically separating corn stalks into short stalks with a length of 5 cm and a width of 1-2 mm.

[0075] (2) Alkali treatment: the short straw is subjected to alkali treatment in a sodium hydroxide solution with a mass percentage concentration of 3%, the mass ratio of the sodium hydroxide solution to the short straw is 30:1, and the temperature of the alkali treatment is 80°C. The alkali treatment time was 1 hour.

[0076] (3) Water washing treatment: the short straw is washed with water after being treated with alkali, and then acid neutralized with dilute hydrochloric acid solution to pH 7 after washing, wherein the concentration of the dilute hydrochloric acid solution is 5%; and then washed with water again after acid neutralizat...

Embodiment 3

[0084] A concrete, the difference from Example 2 is: its components and parts by mass are shown in Table 1.

[0085] In the present embodiment, the preparation method of corn stalk fiber is as follows:

[0086] (1) Mechanically separate corn stalks into short stalks with a length of 10 cm and a width of 1.5 mm.

[0087] (2) Alkali treatment: the short straw is subjected to alkali treatment in a sodium hydroxide solution with a mass percentage concentration of 5%, the mass ratio of the sodium hydroxide solution to the short straw is 40:1, and the temperature of the alkali treatment is 90°C. The alkali treatment time was 1.5 hours.

[0088] (3) Water washing treatment: the short straw is washed with water after being treated with alkali, and then acid neutralized with a dilute hydrochloric acid solution until the pH is 7, and the concentration of the dilute hydrochloric acid solution is 15%. Wash again after acid neutralization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com