Plastering mortar prepared by using construction wastes and phosphogypsum

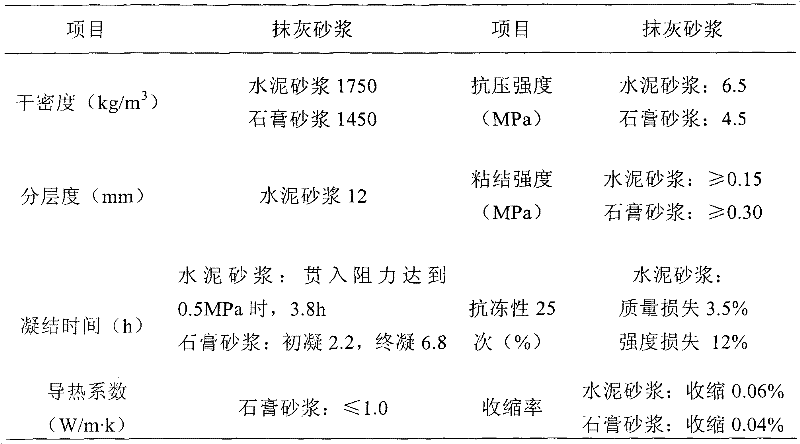

A technology for plastering mortar and construction waste, applied in the field of plastering mortar, which can solve problems such as poor construction performance, low bonding strength, and poor water retention, and achieve the effects of improving strength, reducing production costs, and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

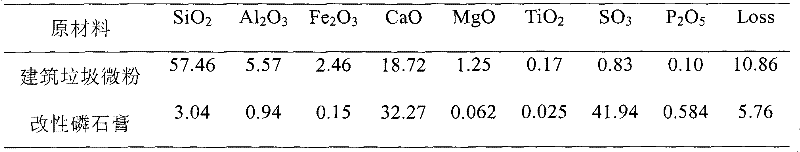

[0038] 1. Preparation of construction waste micropowder: After crushing, screening, and secondary crushing of waste concrete, the separation of aggregate and mortar can be realized. The particle size of mortar powder is ≤5mm, and it is ground in a ball mill until the specific surface area is 3000cm 2 / g, the chemical composition is shown in Table 1.

[0039] 2. Preparation of modified phosphogypsum: Mix phosphogypsum, quicklime and fly ash evenly at a mass ratio of 12:5:1, dry at 80°C for 2 hours, and then use a ball mill to grind until the specific surface area is 3000cm 2 / g to obtain modified phosphogypsum, the chemical composition is shown in Table 1. Among them, the radioactivity of phosphogypsum complies with the relevant requirements of "Limits of Radionuclides in Building Materials" (GB6566-2001).

[0040] 3. The activator is CaSO 4 with Na 2 SiO 3 9H 2 O obtained by mixing in a mass ratio of 1:4.

[0041] 4. According to the weight percentage of each raw materia...

Embodiment 2

[0044] 1. Preparation of construction waste micropowder: After crushing, screening and secondary crushing of waste concrete, the separation of aggregate and mortar can be realized. The particle size of mortar powder is ≤5mm, and it is ground in a ball mill until the specific surface area is 3500cm 2 / g.

[0045] 2. Preparation of modified phosphogypsum: Mix phosphogypsum, quicklime and fly ash evenly at a mass ratio of 13:6:1, dry at 80°C for 2 hours, and then use a ball mill to grind until the specific surface area is 3000cm 2 / g to obtain modified phosphogypsum. Among them, the radioactivity of phosphogypsum complies with the relevant requirements of "Limits of Radionuclides in Building Materials" (GB6566-2001).

[0046] 3. The activator is CaSO 4 with Na 2 SiO 3 9H 2 O obtained by mixing in a mass ratio of 1:2.

[0047] 4. According to the weight percentage of each raw material: cement 10%, modified phosphogypsum 20%, construction waste powder 25%, sand 40%, activator...

Embodiment 3

[0049] 1. Preparation of construction waste micropowder: After crushing, screening, and secondary crushing of waste concrete, the separation of aggregate and mortar can be realized. The particle size of mortar powder is ≤5mm, and it is ground in a ball mill until the specific surface area is 3000cm 2 / g.

[0050] 2. Preparation of modified phosphogypsum: Mix phosphogypsum, quicklime and fly ash evenly in a mass ratio of 8:4:1, dry at 80°C for 2 hours, and then use a ball mill to grind until the specific surface area is 3300cm 2 / g to obtain modified phosphogypsum. Among them, the radioactivity of phosphogypsum complies with the relevant requirements of "Limits of Radionuclides in Building Materials" (GB6566-2001).

[0051] 3. The activator is CaSO 4 with Na 2 SiO 3 9H 2 O mixed in a mass ratio of 1:3.

[0052] 4. According to the weight percentage of each raw material: cement 12%, modified phosphogypsum 23%, construction waste powder 25%, sand 36%, activator: 3.7%, water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com