Series biaxial high-efficiency powder separator

A biaxial, powder selection technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of reduced separation efficiency, large fluctuations in coal fineness, and power output of the pulverizing system. Large and other problems, to achieve the effect of high uniformity index of pulverized coal, high sorting efficiency and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

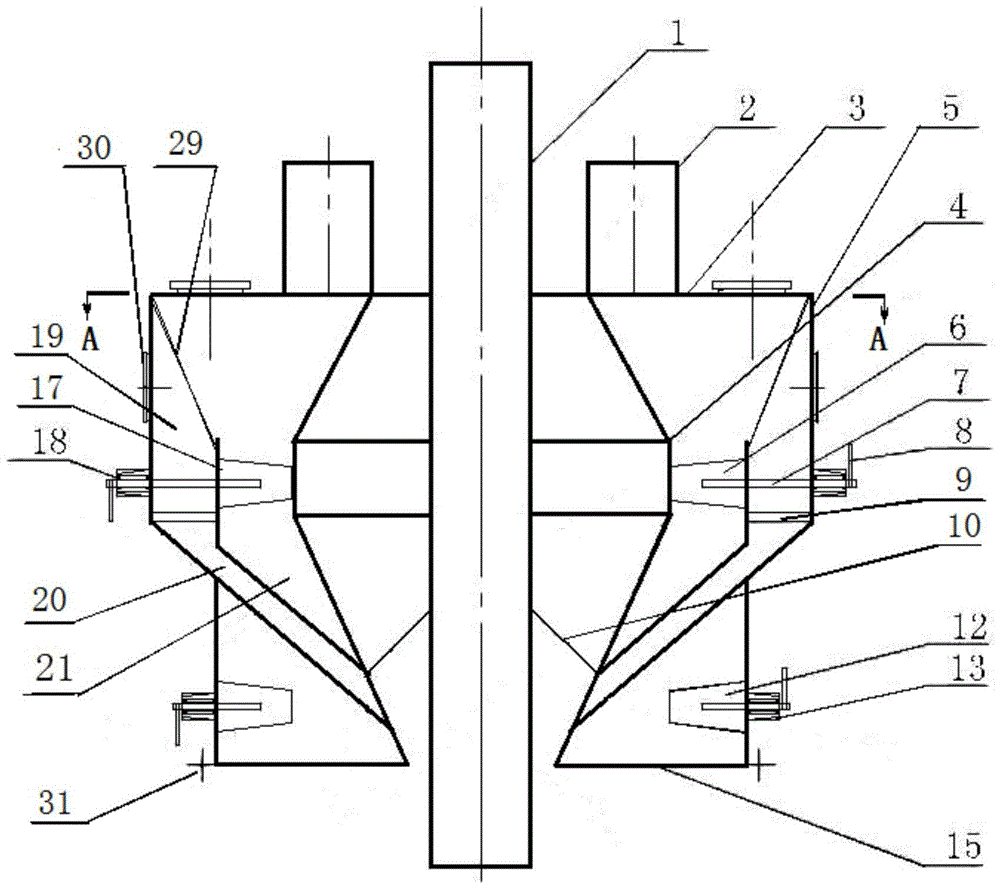

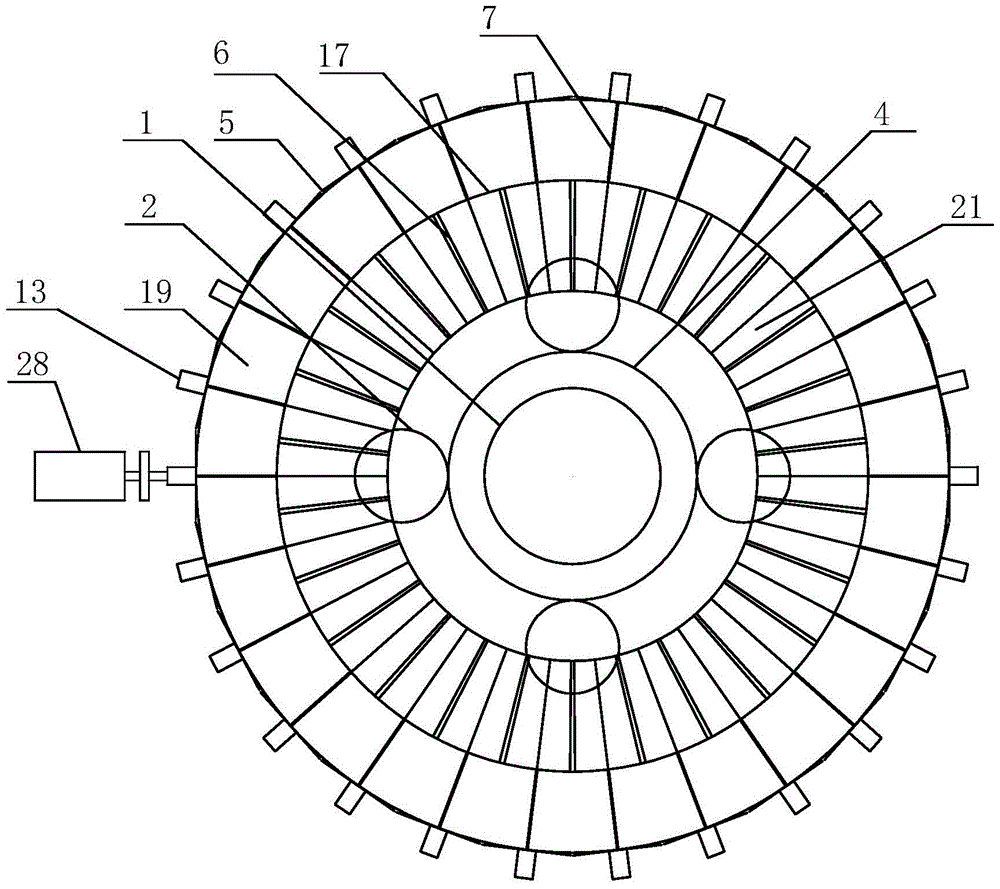

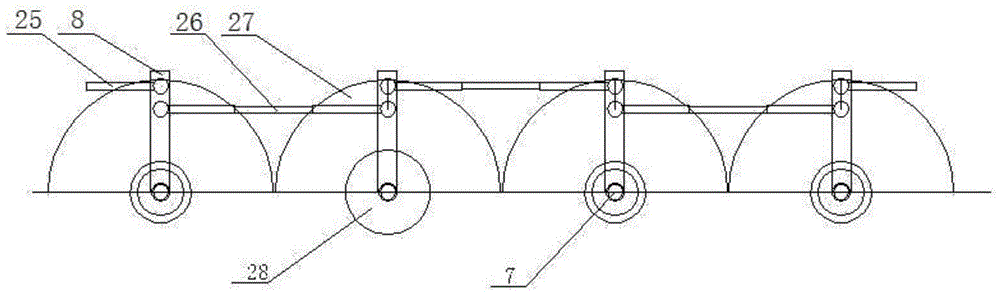

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 As shown, the series biaxial powder separation device includes sequentially arranged from the center of the device to the outside: a coal falling pipe 1, an inner cone 4 whose middle part is passed through by the coal falling pipe, and the outermost shell 5. The upper end surface of the powder selection device is provided with a cover plate 3 whose center is pierced by the coal falling pipe. The primary air duct 2 is fixed on the cover plate or outside the upper part of the shell, and the shell and the inner cone A sorting passage 21 communicating with the primary air duct from bottom to top is formed between them. The lower end surface of the shell is open, and is fixedly provided with a flange 31 that is connected to the upper outlet of the coal mill below. The air-powder mixture coming from the outlet of the coal mill spirally rotates upwards and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com