Environment-friendly high-performance waterproof flame-retardant plastering mortar and preparation method thereof

A plastering mortar and high-performance technology, which is applied in the field of silicate building materials, can solve problems such as high production cost, collapse, and hollowing of the plaster layer on the wall, so as to reduce production costs, prevent flames from spreading, and improve work sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of modified expandable graphite: according to the mass ratio flake graphite: KMnO 4=1:0.3 ratio to add KMnO to flake graphite 4 , stir well, add 70% HClO 3 solution, maintaining a solid-to-liquid ratio of 1:4, and keeping intermittent stirring at 35°C for 90 minutes, followed by washing with water, suction filtration, drying, and grinding until the particle size is 0.05-1mm, and the modified expandable graphite can be obtained. The expansion volume is 500~600ml / g;

[0032] 2) Preparation of modified phosphogypsum: Mix phosphogypsum, quicklime and fly ash evenly in a mass ratio of 13:5:1, dry or fry at 80°C for 3 hours, and then grind until the specific surface area is 2500 ~3500cm 2 / g to obtain modified phosphogypsum, wherein the radioactivity of phosphogypsum meets the relevant requirements of GB6566-2001;

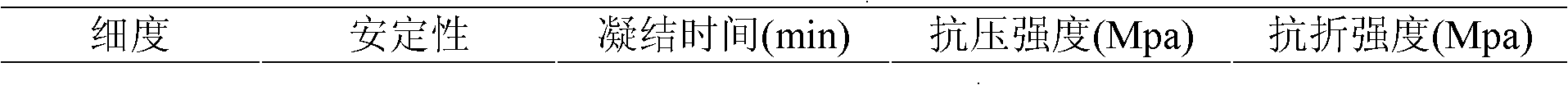

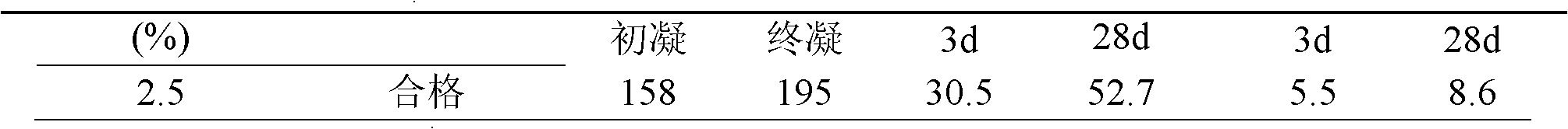

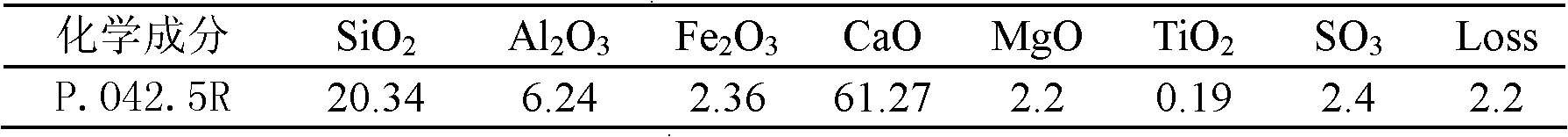

[0033] 3) Preparation of plastering mortar: P.O42.5R cement, modified phosphogypsum, redispersible latex powder, limestone powder, ceramic micr...

Embodiment 2

[0037] 1) Preparation of modified expandable graphite: according to the mass ratio flake graphite: KMnO 4 =1:0.4 ratio to add KMnO to flake graphite 4 , stir well, add 75% HClO 3 Solution, maintain a solid-liquid ratio of 1:4, keep at 35°C for 80 minutes with intermittent stirring, then wash with water, filter with suction, dry, and grind until the particle size is 0.05-1mm to obtain modified expandable graphite with an expansion volume of 500 ~600ml / g;

[0038] 2) Preparation of modified phosphogypsum: Mix phosphogypsum, lime and fly ash evenly at a mass ratio of 12:5:1, dry or fry at 80°C for 2.5 hours, and then grind until the specific surface area is 2500~3500cm 2 / g to obtain modified phosphogypsum, wherein the radioactivity of phosphogypsum meets the relevant requirements of GB6566-2001;

[0039] 3) Preparation of plastering mortar: P.O42.5R cement, modified phosphogypsum, redispersible latex powder, limestone powder, ceramic microbeads, modified expandable graphite,...

Embodiment 3

[0042] 1) Preparation of modified expandable graphite: Use flake graphite, hydrogen peroxide, and fuming nitric acid to stir rapidly in an ice-water bath until the reaction becomes gentle. ≥99.5% acetic acid solution with constant stirring, react for 60min, wash with water, filter with suction, and dry to obtain sulfur-free and ash-free modified expandable graphite with an expansion volume of 300-350ml / g, of which flake graphite, fuming nitric acid, hydrogen peroxide , the ratio of acetic acid is 5 (g): 12 (ml): 1 (ml): 5 (ml);

[0043] 2) Preparation of modified phosphogypsum: Mix phosphogypsum, lime and fly ash uniformly at a mass ratio of 13:5:1, dry or fry at 80°C for 3 hours, and then grind until the specific surface area is 2500 ~3500cm 2 / g to obtain modified phosphogypsum, wherein the radioactivity of phosphogypsum meets the relevant requirements of GB6566-2001;

[0044] 3) Preparation of plastering mortar: P.O42.5R cement, modified phosphogypsum, redispersible latex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com