Mimic ecological odor-less spackling compound

A putty paste and ecological imitation technology, which is applied in the field of building decoration materials to achieve the effects of stable performance, enhanced breathing depth, and reduced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

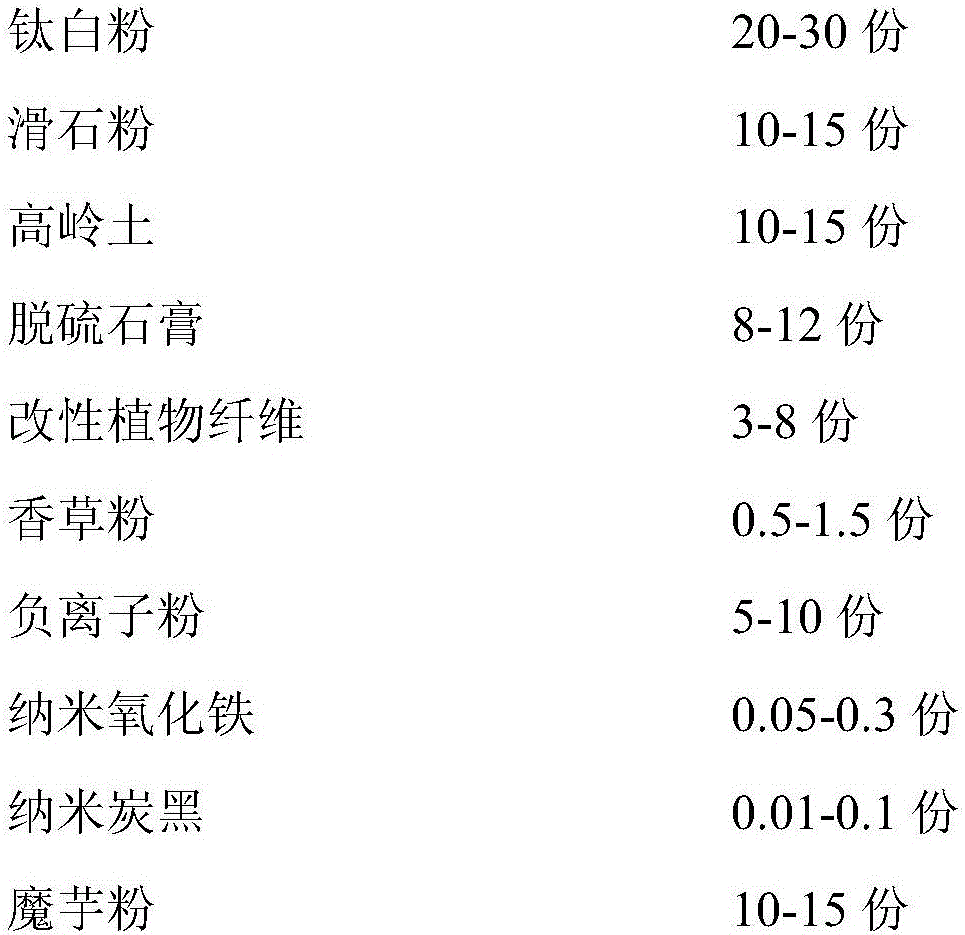

Method used

Image

Examples

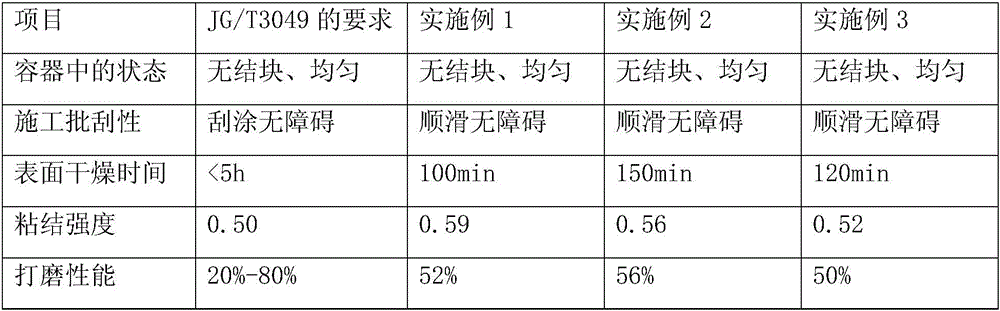

Embodiment 1

[0030] 20 parts of titanium dioxide, 15 parts of talcum powder, 15 parts of kaolin, 10 parts of desulfurized gypsum, 5 parts of modified plant fiber, 0.5 parts of vanilla powder, 8 parts of negative ion powder, 0.1 part of nano-iron oxide, 0.05 part of nano-carbon black, konjac powder 10 parts, 35 parts of water; the preparation method is as follows, weigh each component according to the above ratio, first add a sufficient amount of water into the putty paste mixing tank, first add konjac powder and start the mixer to stir evenly at a speed of 500r / min , stirred for 10 minutes, then added titanium dioxide, talcum powder, kaolin, desulfurized gypsum and stirred evenly at a speed of 500r / min, stirred for 10 minutes, then added modified cellulose, vanilla powder, negative ion powder, nano-iron oxide and nano-carbon black Stir evenly at a constant speed at 1000r / min, stir for 10 minutes, turn off the agitator and let stand for 10-15 minutes, then rotate at 800r / min, stir for 3-5 mi...

Embodiment 2

[0032] 30 parts of titanium dioxide, 12 parts of talcum powder, 15 parts of kaolin, 12 parts of desulfurized gypsum, 4 parts of modified plant fiber, 1 part of vanilla powder, 5 parts of negative ion powder, 0.08 parts of nano-iron oxide, 0.1 part of nano-carbon black, konjac powder 15 parts, 40 parts of water; the preparation method is as follows, weigh each component according to the above ratio, first add a sufficient amount of water into the putty paste mixing tank, first add konjac powder and start the mixer to stir evenly at a speed of 500r / min , stirred for 10 minutes, then added titanium dioxide, talcum powder, kaolin, desulfurized gypsum and stirred evenly at a speed of 500r / min, stirred for 10 minutes, then added modified cellulose, vanilla powder, negative ion powder, nano-iron oxide and nano-carbon black Stir evenly at a constant speed at 1000r / min, stir for 10 minutes, turn off the agitator and let stand for 10-15 minutes, then rotate at 800r / min, stir for 3-5 minu...

Embodiment 3

[0034] 25 parts of titanium dioxide, 15 parts of talcum powder, 10 parts of kaolin, 8 parts of desulfurized gypsum, 8 parts of modified plant fiber, 0.8 parts of vanilla powder, 10 parts of negative ion powder, 0.3 parts of nano-iron oxide, 0.06 parts of nano-carbon black, konjac powder 12 parts, 38 parts of water; the preparation method is as follows, weigh each component according to the above ratio, first add a sufficient amount of water into the putty paste mixing tank, first add konjac powder and start the mixer to stir evenly at a speed of 500r / min , stirred for 10 minutes, then added titanium dioxide, talcum powder, kaolin, desulfurized gypsum and stirred evenly at a speed of 500r / min, stirred for 10 minutes, then added modified cellulose, vanilla powder, negative ion powder, nano-iron oxide and nano-carbon black Stir evenly at a constant speed at 1000r / min, stir for 10 minutes, turn off the agitator and let stand for 10-15 minutes, then rotate at 800r / min, stir for 3-5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com