Electrolytic manganese residue harmless processing composition

A technology of harmless treatment and electrolysis of manganese slag, applied in the direction of fertilizer mixture, application, inorganic fertilizer, etc., can solve the problems of high energy consumption, high cost, high processing cost, etc., and achieve reduction in processing cost, energy consumption, and operation steps simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

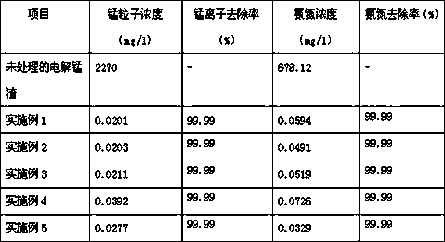

Examples

Embodiment 1

[0041] Step 1, add 0.1 part of phosphate into container 1, stir and react for 1 minute to obtain product 1;

[0042] Step 2, add 10 parts of a mixture of magnesium hydroxide and magnesium oxide to the product 1, the mixing ratio is: 1:6, stir and react for 30 minutes to obtain the product 2;

[0043] Step 3: Add 0.1 part of carboxylic acid to product 2, stir and react for 2 minutes to obtain harmless electrolytic manganese slag.

[0044] The compound phosphate comprises the following components in parts by weight:

[0045] Tripolyphosphate 40 parts

[0046] Hexametaphosphate 40 parts

[0047] Trisodium Phosphate 10 parts.

[0048] Described carboxylic acid comprises following composition in parts by weight:

[0049] Tartaric acid 20 parts

[0050] 70 parts of citric acid.

Embodiment 2

[0052] Step 1, add 0.05 part of phosphate into container 2, and stir to react for 0.5min to obtain product 1;

[0053] Step 2, add 5 parts of a mixture of magnesium hydroxide and magnesium oxide to product 1, the mixing ratio is 1:8, and stir for 25 minutes to obtain product 2;

[0054] Step 3: Add 0.05 parts of carboxylic acid to the product 2, stir and react for 1 min to obtain harmless electrolytic manganese slag.

[0055] The compound phosphate comprises the following components in parts by weight:

[0056] Tripolyphosphate 50 parts

[0057] Hexametaphosphate 50 parts

[0058] 20 parts of trisodium phosphate.

[0059] Described carboxylic acid comprises following composition in parts by weight:

[0060] Tartaric acid 30 parts

[0061] 80 parts of citric acid.

Embodiment 3

[0063] Step 1, add 0.2 parts of phosphate in the container 3, stir and react for 2 minutes to obtain product 1;

[0064] Step 2, add 15 parts of a mixture of magnesium hydroxide and magnesium oxide to the product one, the mixing ratio is: 1:9, stir and react for 28 minutes to obtain the product two;

[0065] Step 3: Add 0.2 parts of carboxylic acid to the product 2, stir and react for 2 minutes to obtain harmless electrolytic manganese slag.

[0066] The compound phosphate comprises the following components in parts by weight:

[0067] Tripolyphosphate 50 parts

[0068] Hexametaphosphate 40 parts

[0069] 20 parts of trisodium phosphate.

[0070] Described carboxylic acid comprises following composition in parts by weight:

[0071] Tartaric acid 20 parts

[0072] 70 parts of citric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com