G-class oil well cement and processing technology thereof

A technology for oil well cement and processing technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of serious snowmen in kilns, affecting the production of high-quality oil well cement, and high cost, and achieves improvement of clinker quality and reduction of kiln kilns. The effect of building a snowman and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

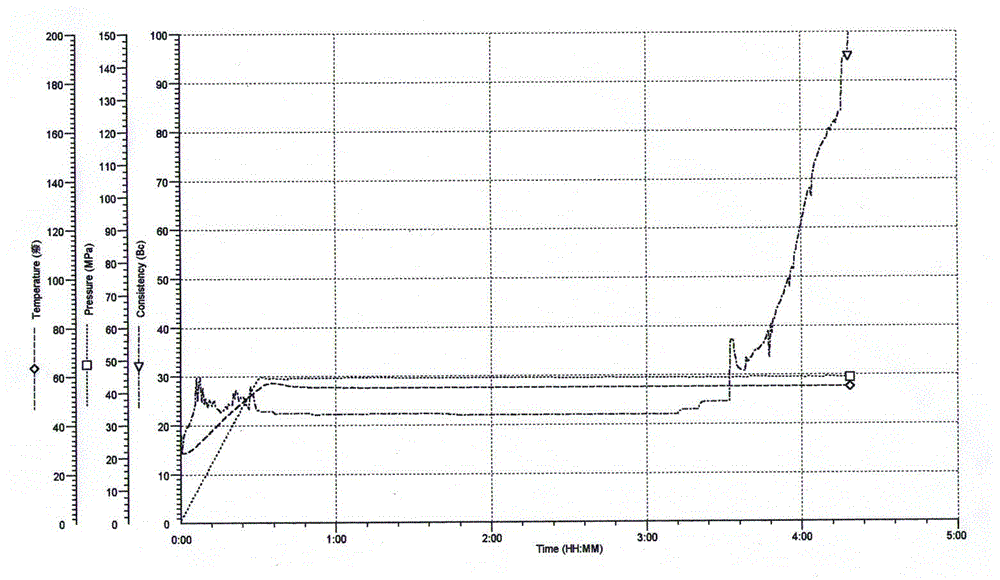

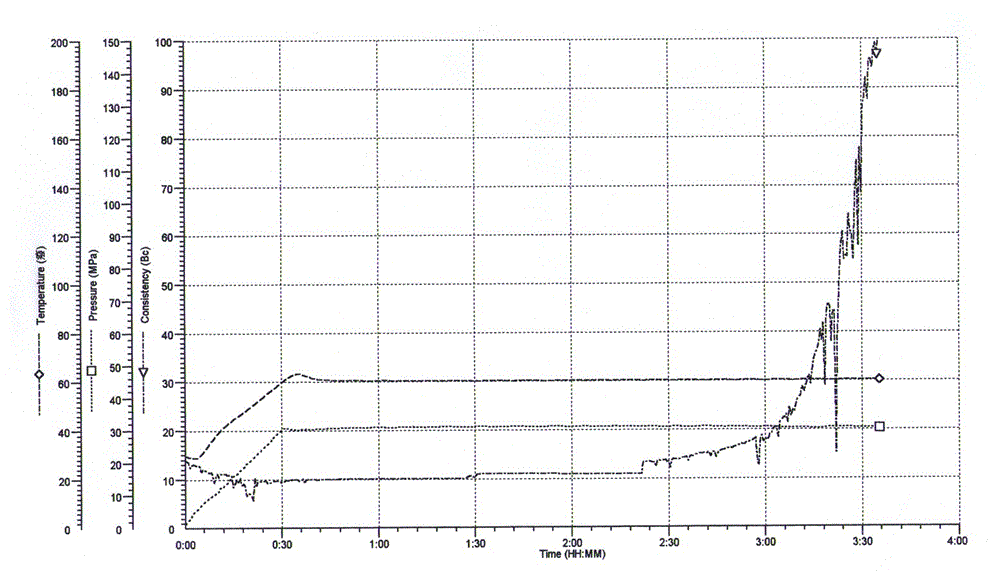

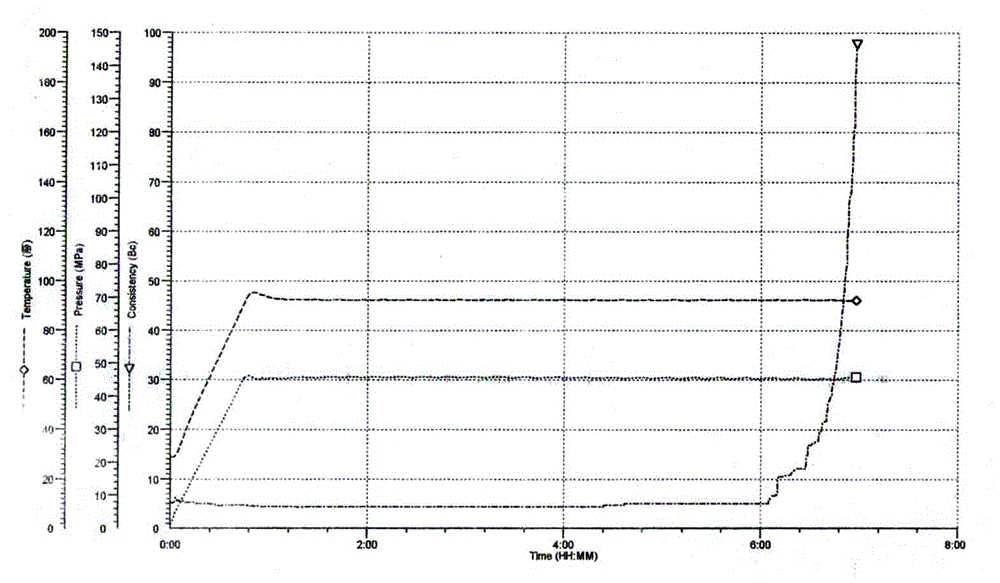

Image

Examples

Embodiment 1

[0023] The present invention will be further described below in conjunction with the examples, but the scope of protection claimed by the invention is not limited to the scope expressed in the examples.

[0024] The specific operation of using coal gangue as siliceous material to produce high-quality oil well cement is as follows:

[0025] 1) The raw materials entering the factory should be as stable as possible, and the main raw materials should use a single ore point as much as possible. The main raw materials are limestone, the siliceous materials are waste rocks from beneficiation, the iron materials are iron ore mining waste rocks, and the aluminum materials are wet powder from power plants. Coal ash and coal are matched with Yushen coal and carbonaceous shale at a ratio of 1:1. Limestone, fly ash, coal gangue, and iron ore mining waste rock are mixed according to the weight ratio and then ground, and the sieve residue of the finished product after the grinding is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com