Dry sintering method and apparatus for aluminum oxide clinker

A technology of sintering device and sintering method, which is applied in the fields of alumina/hydroxide preparation, chemical industry, sustainable manufacturing/processing, etc., and can solve the problem of insufficient utilization of the heat of exhaust gas of the rotary kiln, unclear edge of the flame of the coal injection pipe, and Shape and temperature misjudgment and other problems, to achieve the effect of favorable thermal system, small fluctuation range, and effective clinker quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

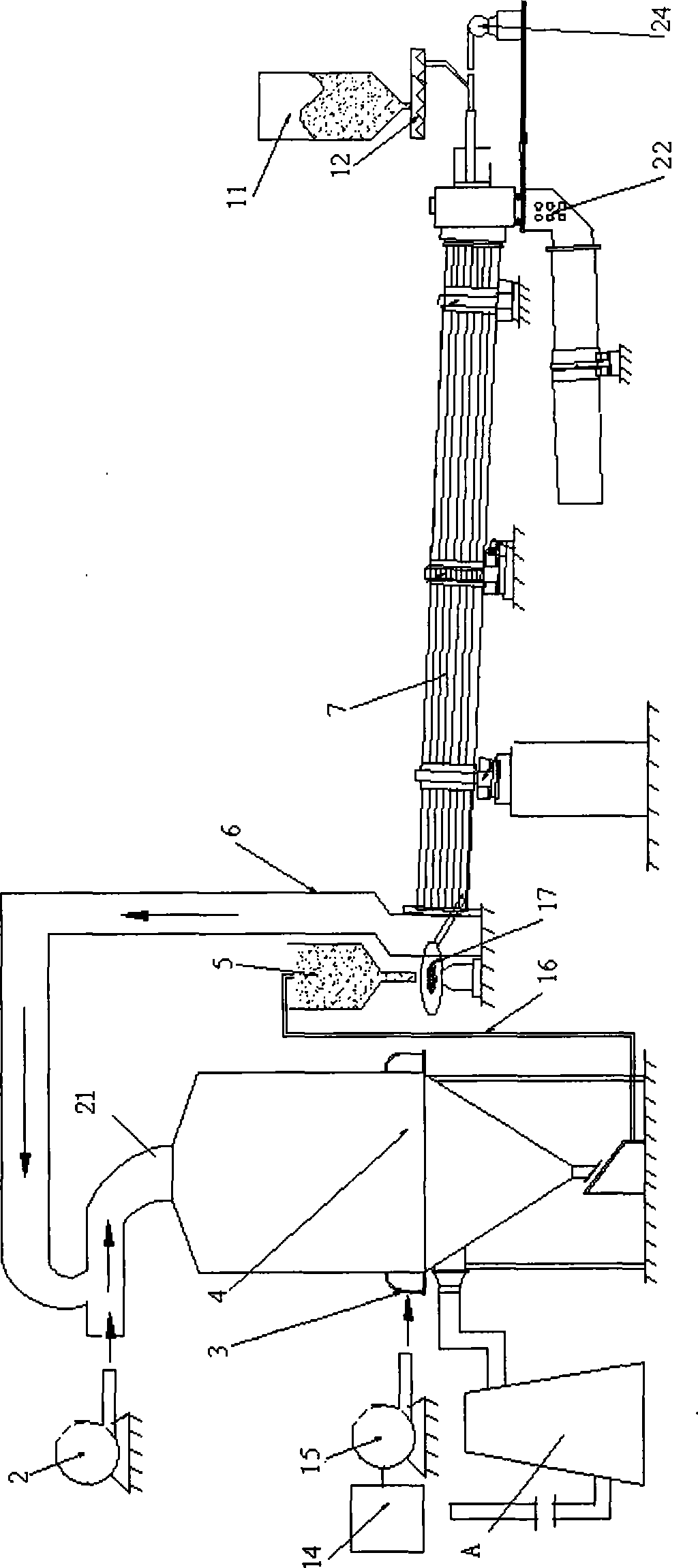

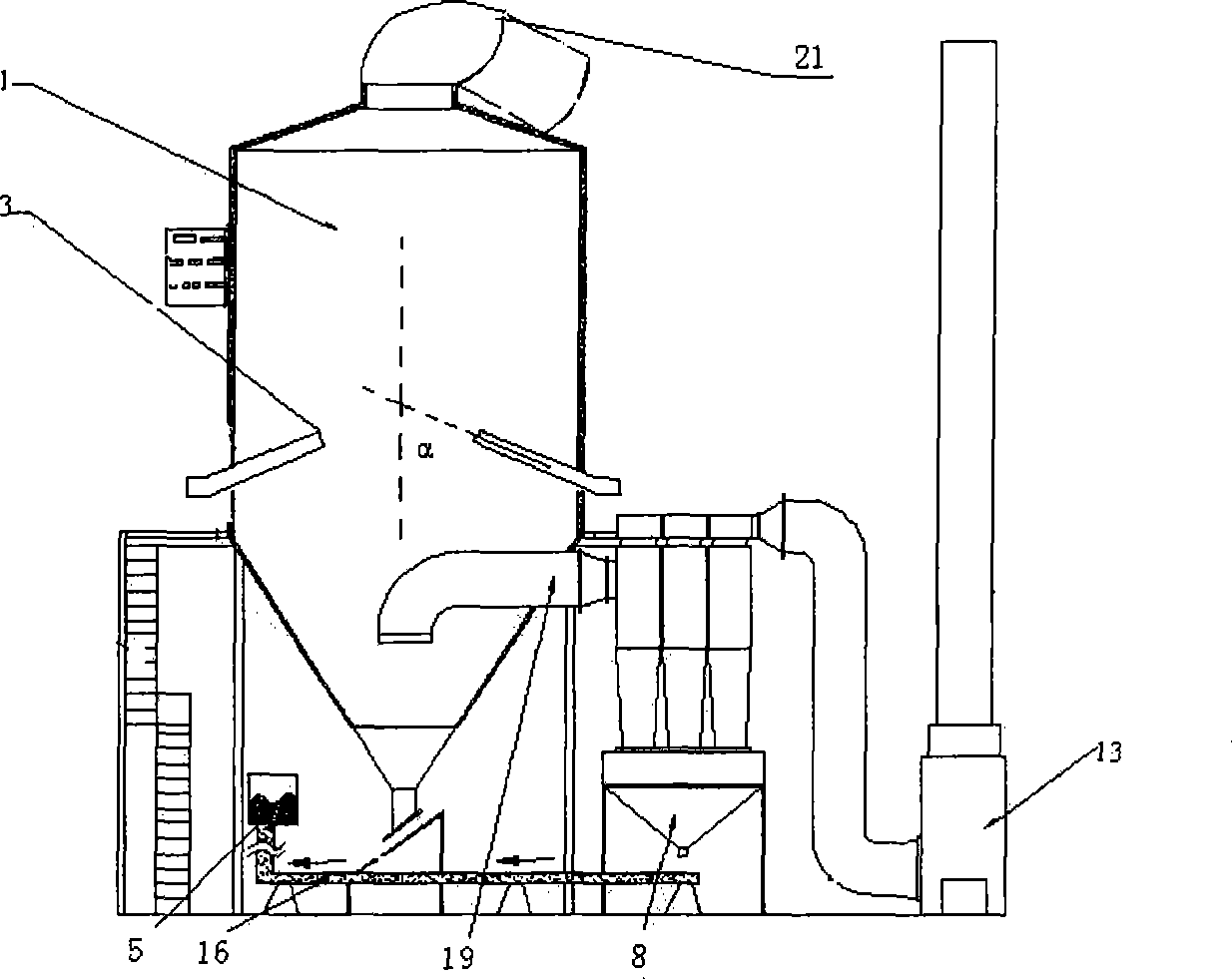

[0042] The raw slurry enters the drying tower (4) from the raw slurry tank (14) and the raw slurry pump (15) through the spray gun (3), and is fully heated with the hot air from the hot blast stove (2) and the kiln tail (6). Exchange to obtain dry raw meal with a moisture content of 3 to 5%. The dry raw meal enters the dry feed bin (5) through the hoist (16), and enters the rotary kiln (7) through the disc feeder (17). Sintering becomes qualified clinker, then falls into the cooler (22) from the kiln head of the rotary kiln, and is discharged from the cooler (22) tail.

Embodiment 2

[0044] Dry raw meal with a moisture content of 3-5% enters the rotary kiln at a ratio of 9:1 to kiln dust, sinters the clinker at a temperature of 1230°C to 1350°C, and discharges it through the tail of the cooler. After measurement, the appearance of the clinker is taupe, the particle size is 10-25mm, the loose specific gravity is 0.95-1.05, η A净 is 97.65%, about 3 percentage points higher than the existing technology, η N净 97.96%, about 1 percentage point higher than the existing technology; the comprehensive energy consumption is 128kg standard coal / t-clinker, about 10kg lower than the existing technology; the output is 72kg / m 3 Kiln volume, about 25kg / m higher than the existing technology 3 Kiln volume.

Embodiment 3

[0046] Dry raw meal with a moisture content of 3-5% enters the rotary kiln at a ratio of 8:2 to kiln dust, sinters the clinker at a temperature of 1230°C to 1350°C, and discharges it through the tail of the cooler. After measurement, the appearance of the clinker is taupe, the particle size is 10-25mm, and the loose specific gravity is 0.97-1.08, η A净 is 97.42%, about 2.7 percentage points higher than the existing technology, η N净 97.63%, about 1 percentage point higher than the existing technology; the comprehensive energy consumption is 131.3kg standard coal / t-clinker, about 6.5kg lower than the existing technology; the output is 68.5kg / m 3 Kiln volume, about 21kg / m higher than the existing technology 3 Kiln volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com