Thermal technology for making acid from gypsum as well as device

A technology of gypsum and acid heat, applied in inorganic chemistry, cement production, sulfur compounds, etc., can solve the problems of high heat consumption, cost increase, and difficult atmosphere coordination of the system, reduce investment and operation costs, increase sulfur dioxide concentration, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

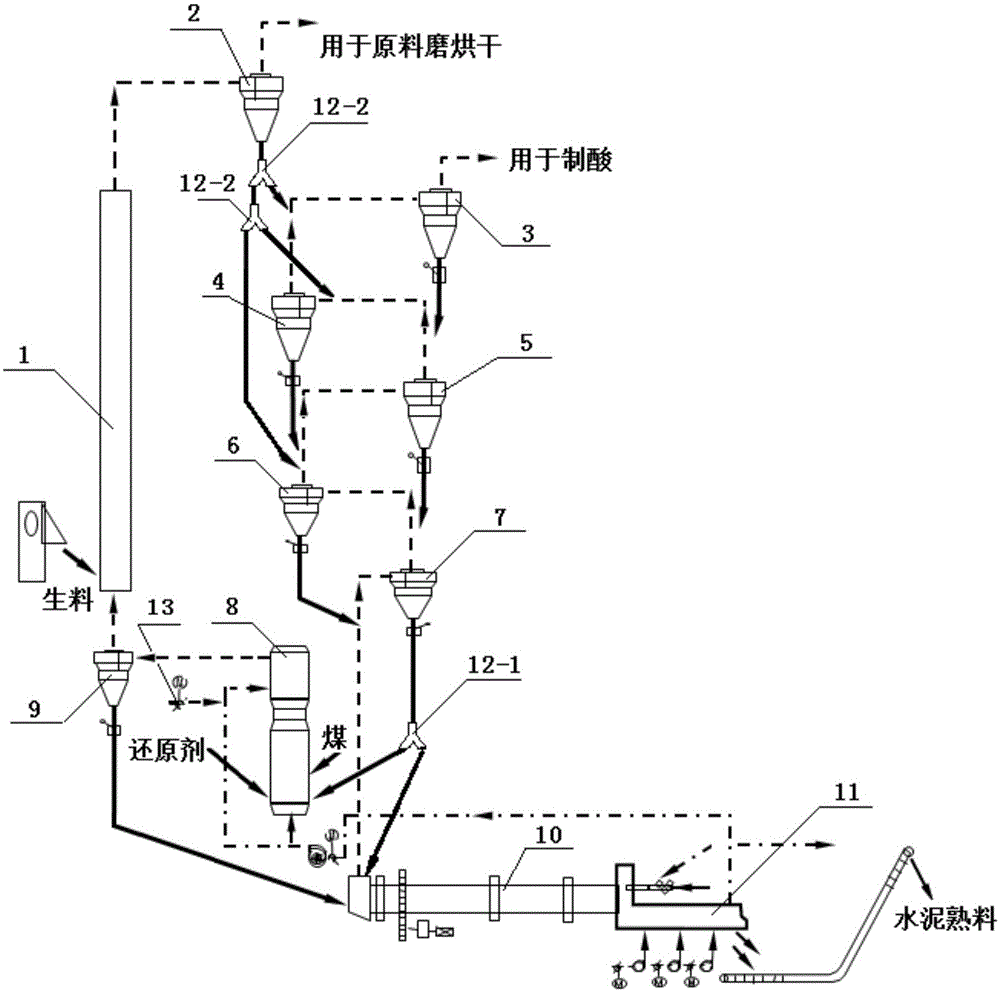

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0023] See figure 1 , a gypsum acid thermal process, comprising the following steps:

[0024] a) Dehydration furnace 1 is used to dry and dehydrate the gypsum raw meal without reducing agent;

[0025] b) The dried and dehydrated raw meal is fed into the multi-stage preheater for full preheating after gas-solid separation;

[0026] c) At least a part of the preheated raw meal is fed into the pre-reduction furnace 8, and the remainder is fed into the rotary kiln 10; in the pre-reduction furnace 8, carbon monoxide is used as a reducing agent, which will account for 20% of the total amount of calcium sulfate in the gypsum raw meal. ~35% of the calcium sulfate was reduced to calcium sulfide. The pre-reduction furnace 8 uses carbon monoxide as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com