Method and device for supplying primary air for kiln head of cement kiln

A technology of supply device and cement kiln, which is applied in combustion method, combustion air/fuel supply, furnace and other directions, can solve problems such as energy consumption gap, and achieve obvious effect, improve coal saving effect, and save coal consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

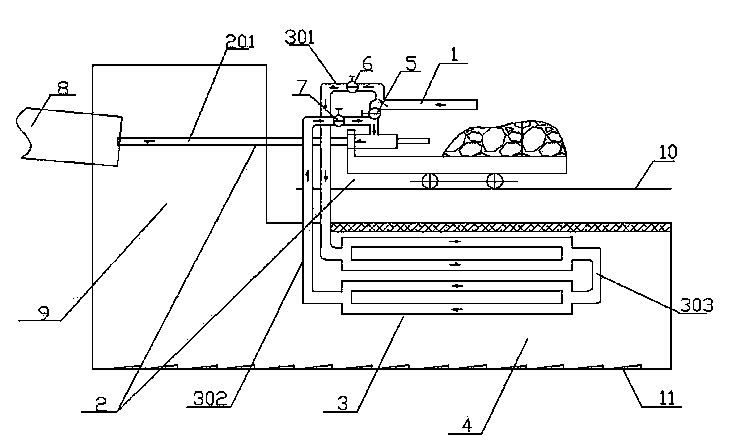

[0012] In conjunction with the accompanying drawings, the most preferred process of the present invention and its device are described in detail;

[0013] The method for supplying primary air at the head of a cement kiln includes the steps of providing primary air to a burner by a Roots blower, and providing pulverized coal fuel and primary air to a rotary kiln from the burner, and also includes a step of heating the primary air. The Roots blower provides The primary air that comes out is heated by the heater to ensure that the air temperature of the primary air increases by 150~200℃, and the heated primary air enters the burner. The effect brought by the heating and supplying process of the primary air can be calculated from three aspects; first, the volume of the primary air expands due to the heating. After calculation, the primary air is heated from the normal temperature of 30°C to 250°C, and the original flow rate remains unchanged. On the basis of , its normal temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com