Preparation method of magnesium calcium clinker

A technology of clinker and magnesium-calcium, which is applied in the field of preparation of magnesium-calcium clinker, can solve the problems that magnesite powder cannot be used, and achieve the effects of promoting reasonable and efficient comprehensive utilization, improving the quality of clinker, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

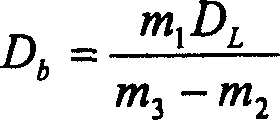

Method used

Image

Examples

Embodiment 1

[0034] Liaoning Dashiqiao abandoned magnesite powder (particle size range 0.001-40mm) and Zhejiang Hangzhou limestone ore were used as raw materials, and the chemical composition is shown in Table 1.

[0035] MgO

CaO

SiO 2

Al 2 O 3

Fe 2 O 3

LOI

magnesite

46.56

0.41

1.38

0.25

0.47

50.92

limestone

0.08

55.08

0.28

0.75

0.04

43.65

[0036] ① Lightly burn. In a rotary kiln, a suspension roasting kiln, a multi-layer furnace, a boiling furnace or a reverberatory furnace, the above-mentioned raw materials are added, and ashless fuel is used for light burning at 1000 ° C for 1 hour.

[0037] ② Cool down. The lightly burned minerals are naturally cooled to 100°C in the air.

[0038] ③ Hydration. The cooled light-burned magnesia and light-burned lime are proportioned according to a certain metering ratio, so that the CaO content accounts for 15% of the ...

Embodiment 2

[0047] The magnesite powder and limestone ore used in Example 1 were used as raw materials.

[0048] ① Lightly burn. In a rotary kiln, a suspension roasting kiln, a multi-layer furnace, a boiling furnace or a reverberatory furnace, the above-mentioned raw materials are added, and ashless fuel is used for light burning at 800 ° C for 2 hours.

[0049] ② Cool down. The lightly burned minerals are naturally cooled to 100°C in the air.

[0050] ③ Hydration. The cooled light-burned magnesia and light-burned lime are proportioned according to a certain metering ratio, so that the CaO content accounts for 15% of the total minerals by weight percentage. Put the weighed two minerals together into room temperature water 4 times the volume of the minerals, and hydrate for 40 minutes to hydrate the MgO in the minerals.

[0051] ④ The materials obtained in the above step ③, including minerals and water, are directly added to the ball mill, and ball milled for 2 hours.

[0052] ⑤ Filter....

Embodiment 3

[0059] The magnesite powder and limestone ore used in Example 1 were used as raw materials.

[0060] ① Lightly burn. In a rotary kiln, suspension roasting kiln, multi-layer furnace, boiling furnace or reverberatory furnace, the above-mentioned raw materials are added, and ashless fuel is used for light burning at 900 ° C for 1.5 hours.

[0061] ② Cool down. The lightly burned minerals are naturally cooled to 150°C in the air.

[0062] ③ Hydration. The cooled light-burned magnesia and light-burned lime are batched according to a certain metering ratio, so that the CaO content accounts for 25% of the total minerals by weight percentage. Put the weighed two minerals together into room temperature water 4 times the volume of the minerals, and hydrate for 20 minutes to hydrate the MgO in the minerals.

[0063] ④ The materials obtained in the above step ③, including minerals and water, are directly added to the ball mill, and ball milled for 2 hours.

[0064] ⑤ Filter. Filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com