Sintering technology of cement clinker with directly doped steel slag in cement sintering system rotary kiln

A technology of cement clinker and rotary kiln, which is applied in cement production, etc., to achieve the effects of fewer operators, increased output, and shorter construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention will be further described

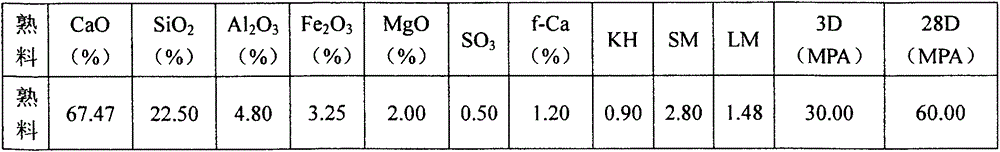

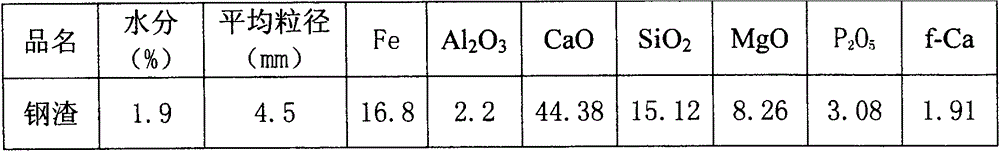

[0026] The steel slag sample comes from a steel plant in Jiangxi. The physical and chemical composition of the steel slag in granular state after hot-seal treatment and magnetic iron removal is shown in Table 2:

[0027] Table 2 Physical and chemical composition of steel slag after hot-hot stuffing treatment and magnetic iron removal in a steel plant in Jiangxi

[0028]

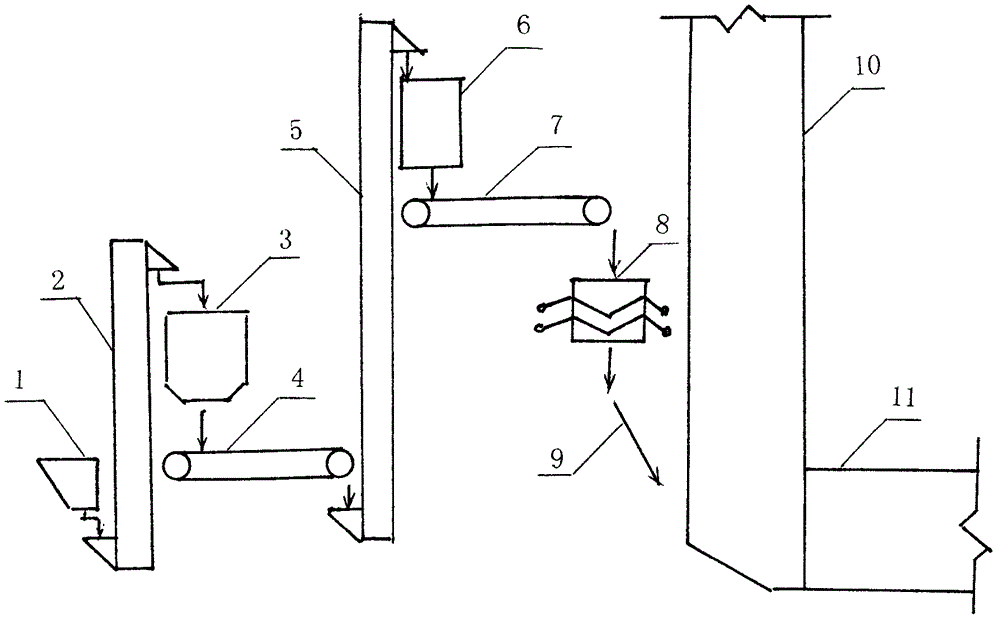

[0029] The technological process of steel slag directly entering the kiln is shown in the attached figure. After the steel slag is poured into the hopper (1), it flows into the material receiving elevator (2) and is lifted into the buffer bin (3), and continuously and steadily flows into the feeding scale (4). The feeding scale weighs the quantitative steel slag according to the set flow rate. And send it into the conveying elevator (5), after being lifted to the platform of the firing preheater kiln tail smoke c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com