Highly active cement mineral forming promoter

An accelerator and high-activity technology, which is applied in the field of new dry process cement production and high-activity cement mineral formation accelerator, can solve the problem that mineralizers cannot meet the requirements of seed crystals and mineralizers, and the fineness of steel slag is difficult to reach cement crystals. Requirements of species, problems affecting clinker quality, production process stability, etc., to achieve the effects of broadening the range of firing, improving ease of firing, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 0.8kg steel slag and 0.2kg mineralizer (chemical composition: SiO 2 3.1%, Al 2 o 3 0.65%, Fe 2 o 3 0.35%, CaO 23.2%, SO 3 23.5%, P 2 o 3 0.7%, CaF 2 48.5%) compound grinding to make an activator with a fineness of 450m 2 / kg, then with a fineness of 350m 2 Mix 4kg of high-calcium ash per kg evenly, and mix it into 95kg of raw meal. The raw meal rate of cement is KH=0.88, n=2.0, p=1.2.

Embodiment 2

[0023] 0.4kg steel slag and 0.6kg mineralizer (chemical composition: SiO 2 3.6%, Al 2 o 3 0.8%, Fe 2 o 3 0.45%, CaO 21.6%, SO 3 24.8%, P 2 o 3 0.5%, CaF 2 48.25%) compound grinding to make an activator with a fineness of 550m 2 / kg, then with a fineness of 450m 2 Mix 11kg / kg slag powder evenly, and mix it into 88kg of raw meal. The raw meal rate of cement is KH=0.98, n=3.0, p=1.8.

Embodiment 3

[0025] 0.6kg steel slag and 0.4kg mineralizer (chemical composition: SiO 2 3.9%, Al 2 o 3 0.72%, Fe 2 o 3 0.42%, CaO 23.9%, SO 3 20.6%, P 2 o 3 0.76%, CaF 2 49.7%) compound grinding, made into activator, the fineness is 500m 2 / kg, then with a fineness of 400m 2 Mix 7kg / kg steel slag powder evenly, and mix it into 92kg of raw meal. The cement raw meal rate values are KH=0.94, n=2.5, p=1.5.

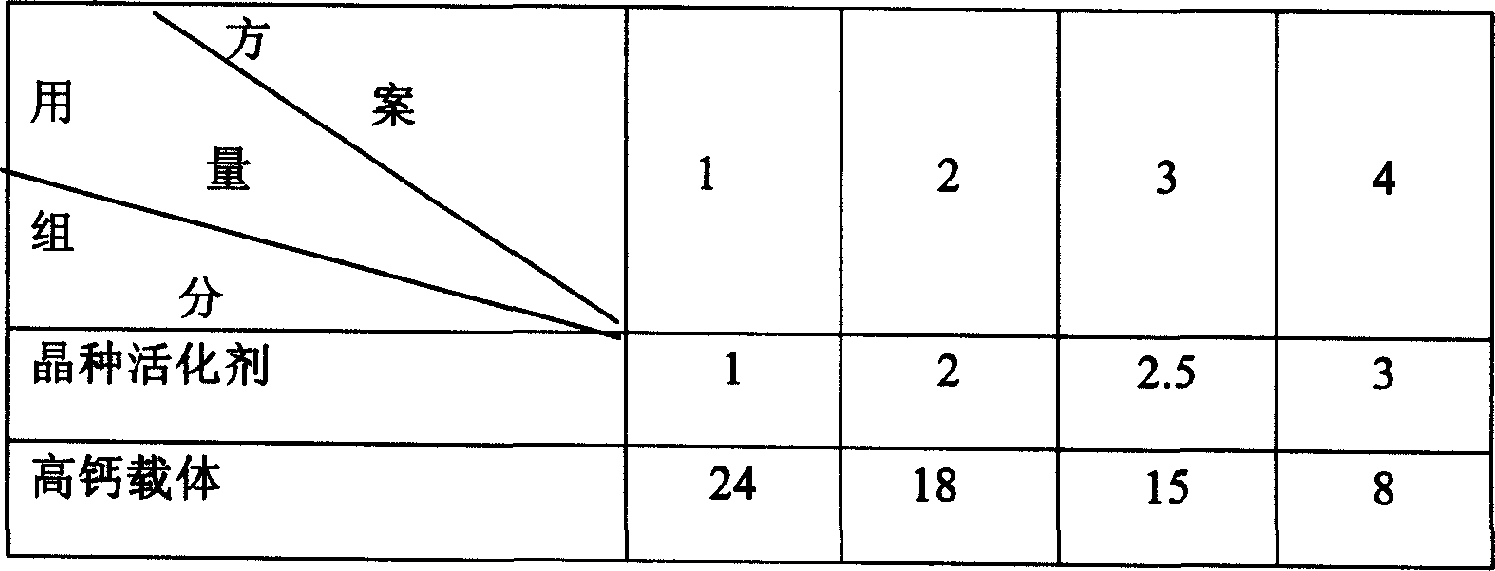

[0026] Attached Table 1: Formula (parts by weight) of highly active cement mineral formation accelerator

[0027]

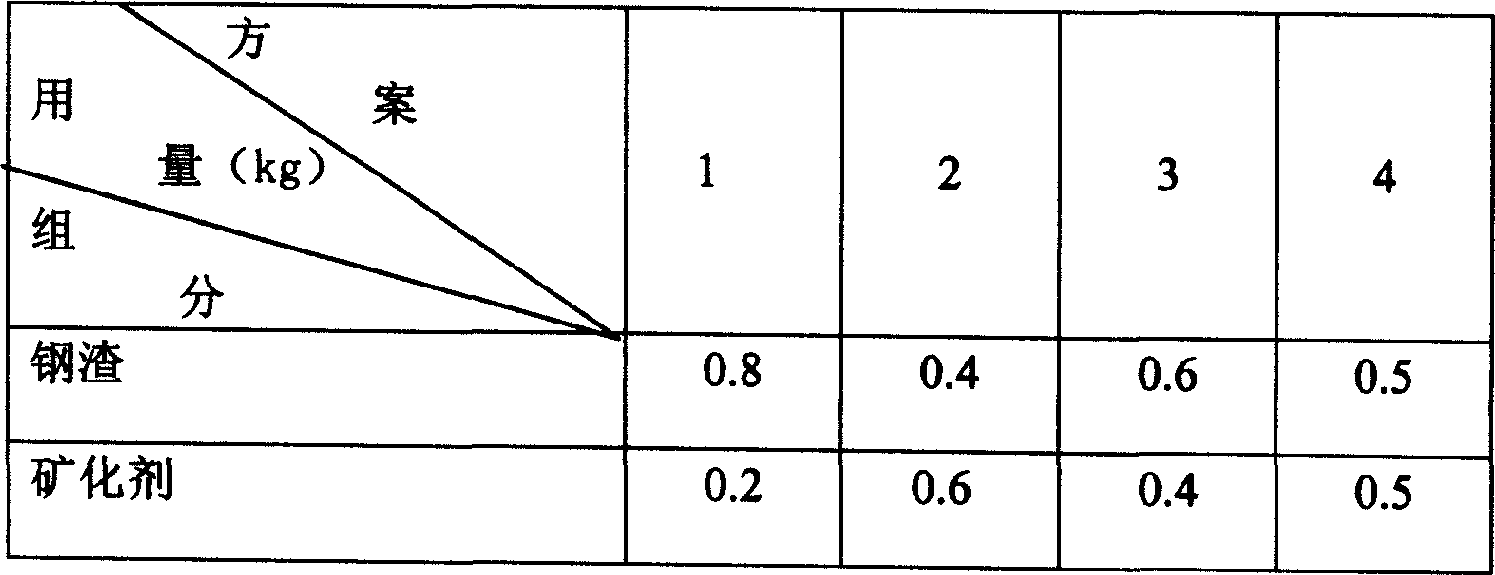

[0028] Attached Table 2: Seed Crystal Activator Formula

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com