Process and processing system for co-processing shellfish waste with cement clinker production line

A cement clinker and production line technology, which is applied in the field of co-processing of shellfish waste in the cement clinker production line and the treatment system, can solve the problems of odor emission, environmental impact, impact, etc., to reduce impact, control pollution, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

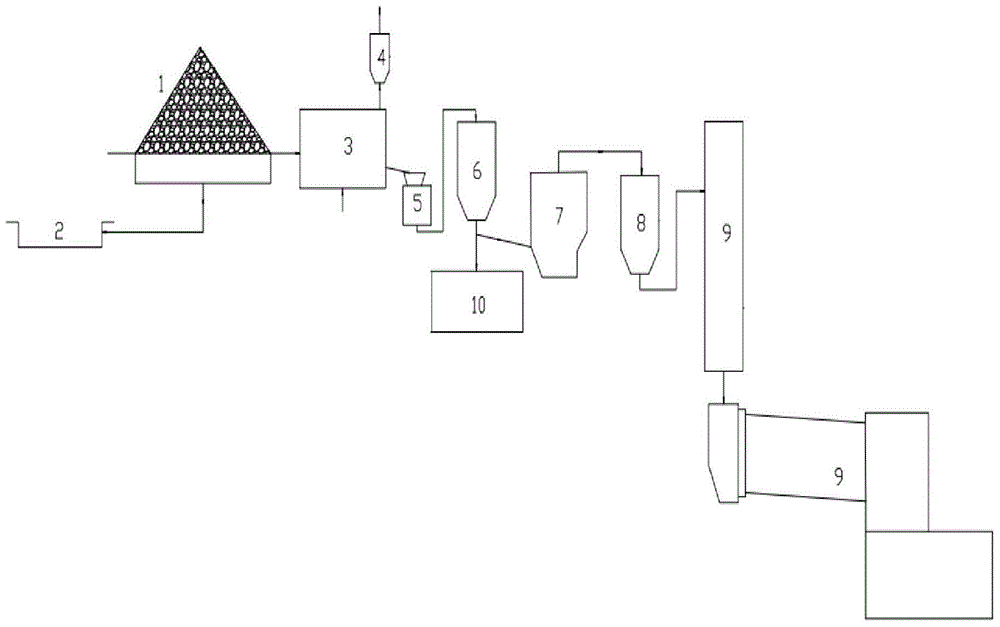

[0026] Such as figure 1 The high-efficiency cement clinker production line co-processing shellfish waste system shown includes a shed 1 with an underground waterway at the bottom for stacking shells, a dryer 3 , a hammer crusher 5 and a storage warehouse 6 . The feed inlet of the dryer 3 is connected to the stack shed 1 through the conveyor belt, and the cleaned shells in the stack shed 1 are sent to the dryer 3 through the conveyor belt, and the air inlet of the dryer 3 is connected to the cement clinker through the pipeline. The air outlet of the bag filter at the end of the rotary kiln of the production line is connected so that the hot air after dust removal at the end of the rotary kiln can be introduced into the dryer to dry the shells. The discharge port of the dryer 3 is connected to the feed port of the hammer crusher 5 via the conveyor belt, the discharge port of the hammer crusher 5 is conveyed to the inlet of the storage 6, and the outlet of the storage 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com